Hollow porous spherical platinum-silver alloy nano-material and preparation method for same

A technology of platinum-silver alloy and nanomaterials, applied in the field of hollow porous spherical platinum-silver alloy nanomaterials and its preparation, to achieve the effects of controllable porous structure, convenient operation and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare a mixed solution of ethylene glycol, polyvinylpyrrolidone, potassium bromide and copper chloride: weigh 1 gram of polyvinylpyrrolidone and add it to 50 ml of ethylene glycol, stir or ultrasonically dissolve, then add 5 mg of potassium bromide and 5 mg of Copper chloride, stirred or ultrasonically dissolved evenly for later use. Then weigh 1 gram of silver nitrate and add it to the above mixed solution and stir or shake to dissolve. Then get 02 grams of chloroplatinic acid and add to the above mixed solution and mix well. Finally, the mixed solution was transferred to a reaction kettle, and then placed in an oven at 160° C. for 240 minutes. Naturally cool to room temperature after stopping heating. After the reaction stopped, the mixture was centrifuged with 400 ml of ethanol and 400 ml of water respectively to obtain platinum-silver alloy nanoparticles. Get 1 gram of platinum-silver alloy nanoparticles and redisperse them in an aqueous solution of polyvinylpy...

Embodiment 2

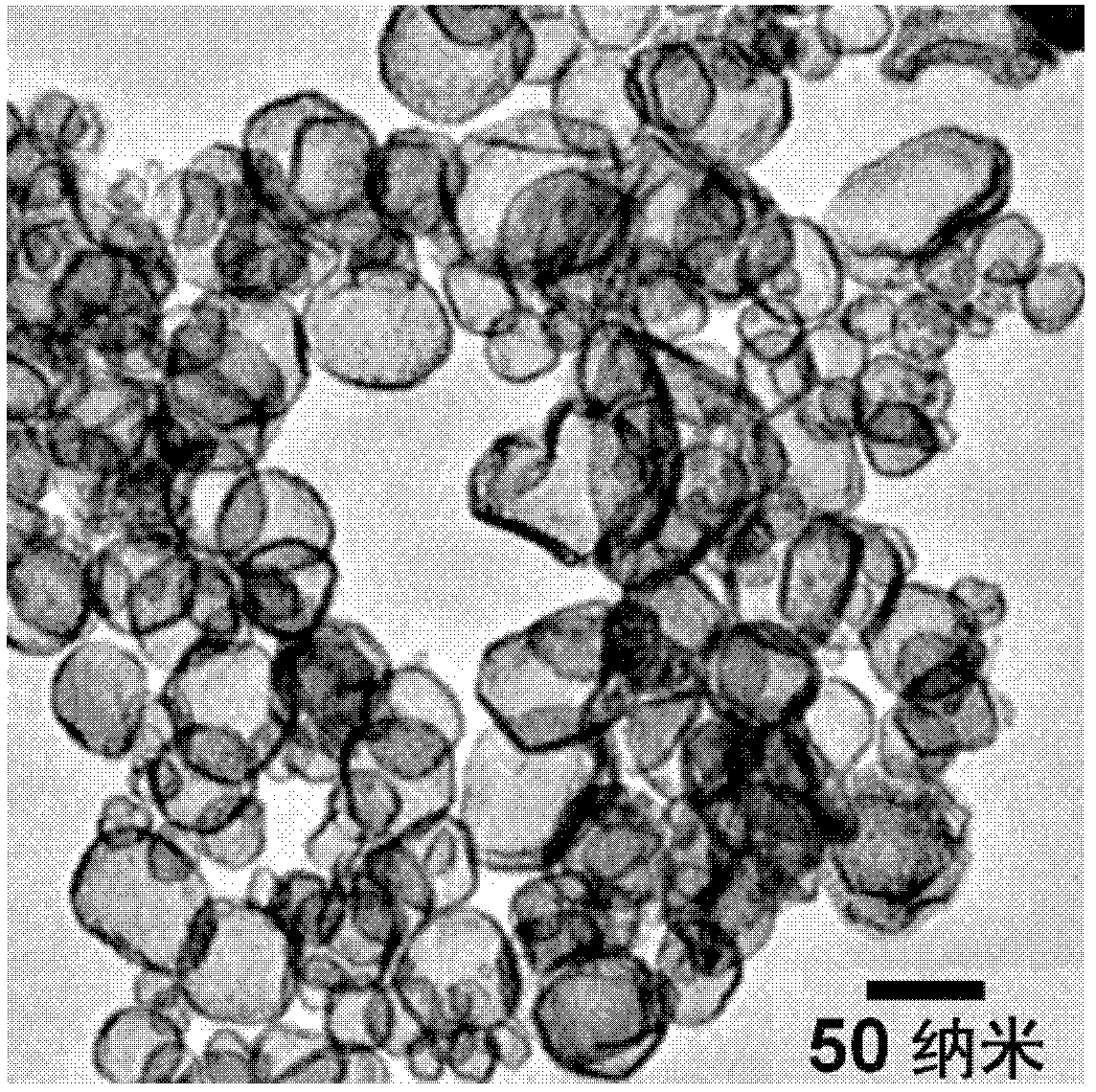

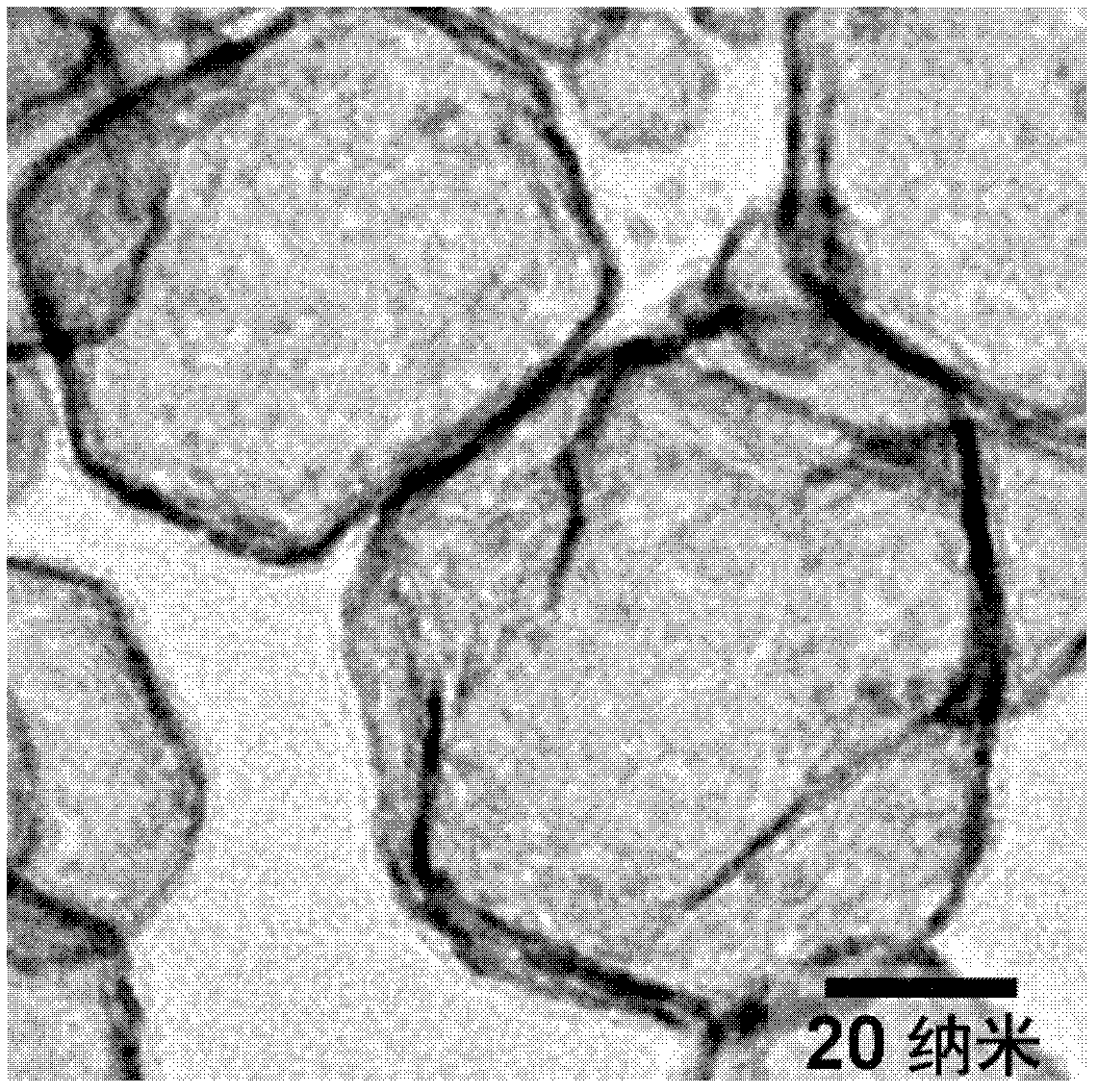

[0042] Example 2: The process is similar to Example 1, but after nitric acid corrosion and centrifugal cleaning, the heating temperature of the product is increased to 200° C. and the heating time is extended to 200 minutes after the product is redispersed in water. Stop heating and cool to room temperature, wash with water and centrifuge to obtain hollow porous spherical platinum-silver alloy nanomaterials with obvious surface pore structure. Figure 4 is a transmission electron microscope image of a hollow porous spherical platinum-silver alloy nanomaterial with a diameter of 50 nanometers, by Figure 4 It can be seen that the surface pore structure is obvious and continuous. Figure 5 This is a high-resolution transmission electron microscope image of this platinum-silver alloy nanomaterial, from which it can be seen that there is a continuous pore wall structure, and the diameter of the pores is between 2 and 10 nanometers. The hollow porous spherical platinum-silver allo...

Embodiment 3

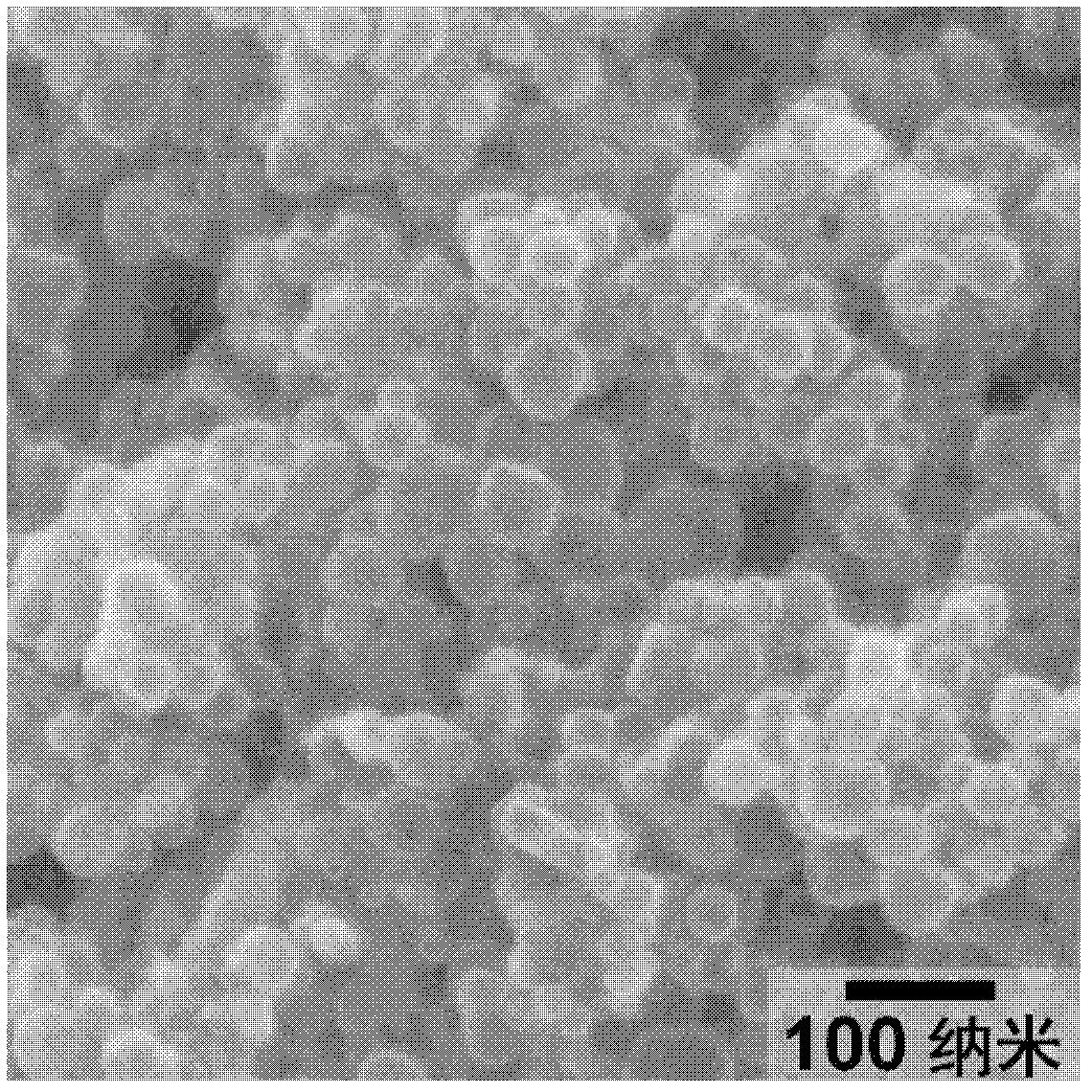

[0043] Embodiment 3: Similar to the process of Embodiment 1, but in the preparation process, ethylene glycol is replaced by glycerol, and all the other conditions remain unchanged. A hollow porous spherical platinum-silver alloy nanomaterial with a diameter of 60 nanometers can be obtained. Image 6 It is a transmission electron microscope image of a hollow porous spherical platinum-silver alloy nanomaterial with a diameter of 60 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com