Preparation method of platinum based/nitrogen doped carbon quantum dot-carbon nanotube catalyst

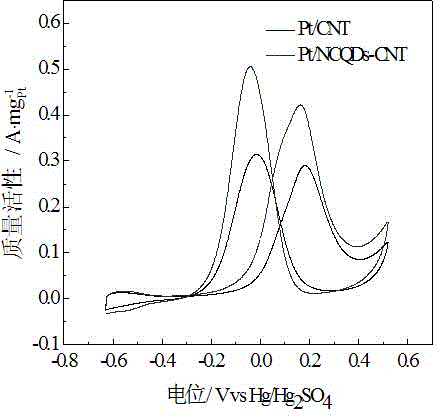

A technology of carbon nanotubes and carbon quantum dots is applied in the field of preparation of new platinum-based catalyst carriers, which can solve problems such as unsatisfactory specific surface area, and achieve the effect of simple and feasible preparation method, improved electrocatalytic activity, and improved activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

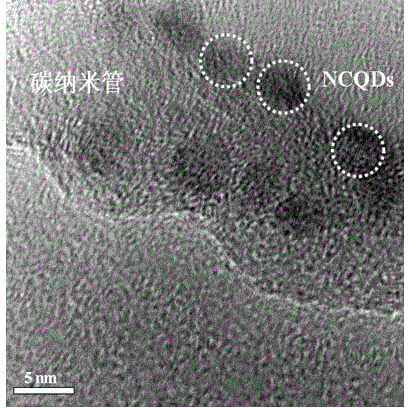

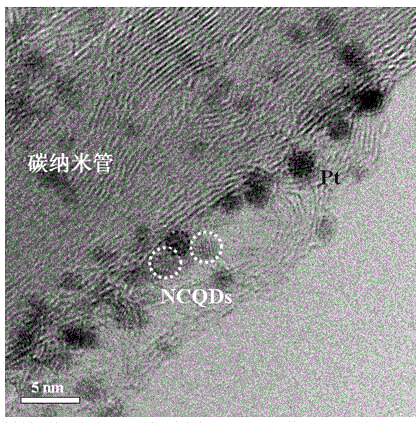

[0029] Specific implementation mode 1: In this implementation mode, platinum-based / nitrogen-doped carbon quantum dot-carbon nanotube catalysts are prepared according to the following steps:

[0030] Weigh 1.0 g of ethylenediaminetetraacetic acid and 20 mL of deionized water and mix them, ultrasonically disperse for 1 h; weigh 20 mg of carbon nanotubes and mix them with ethylenediaminetetraacetic acid solution, and place the mixture in a 50 mL Teflon sealed jar In 140 °C, hydrothermal treatment for 1 h, after cooling to room temperature, washing with deionized water, vacuum drying at 80 °C, to obtain nitrogen-doped carbon quantum dot-carbon nanotube support. The platinum-based catalyst was prepared by microwave-assisted reduction of ethylene glycol.

specific Embodiment approach 2

[0031] Specific embodiment 2: In this embodiment, platinum-based / nitrogen-doped carbon quantum dot-carbon nanotube catalysts are prepared according to the following steps:

[0032] Weigh 3.0 g of citric acid and urea (1:1) and mix with 20 mL of deionized water, ultrasonically disperse for 2 h; weigh 20 mg of carbon nanotubes and mix with the solution, and place the mixture in a 50 mL Teflon sealed jar In 160 °C, hydrothermal for 4 h, after being cooled to room temperature, washed with deionized water, and vacuum-dried at 60 °C to obtain nitrogen-doped carbon quantum dot-carbon nanotube support. The platinum-based catalyst was prepared by microwave-assisted reduction of ethylene glycol.

specific Embodiment approach 3

[0033] Specific embodiment three: In this embodiment, platinum-based / nitrogen-doped carbon quantum dot-carbon nanotube catalysts are prepared according to the following steps:

[0034] Weigh 2.0 g of glucose and glycine (1:1) and mix with 20 mL of deionized water, ultrasonically disperse for 3 h; weigh 20 mg of carbon nanotubes and mix with the solution, and place the mixture in a 50 mL Teflon sealed jar , heated at 180 °C for 8 h, cooled to room temperature, washed with deionized water, and dried in vacuum at 80 °C to obtain a nitrogen-doped carbon quantum dot-carbon nanotube carrier. The platinum-based catalyst was prepared by microwave-assisted reduction of ethylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com