Fe-Co-P-C amorphous electro-catalyst for efficient hydrogen evolution reaction and preparation method thereof

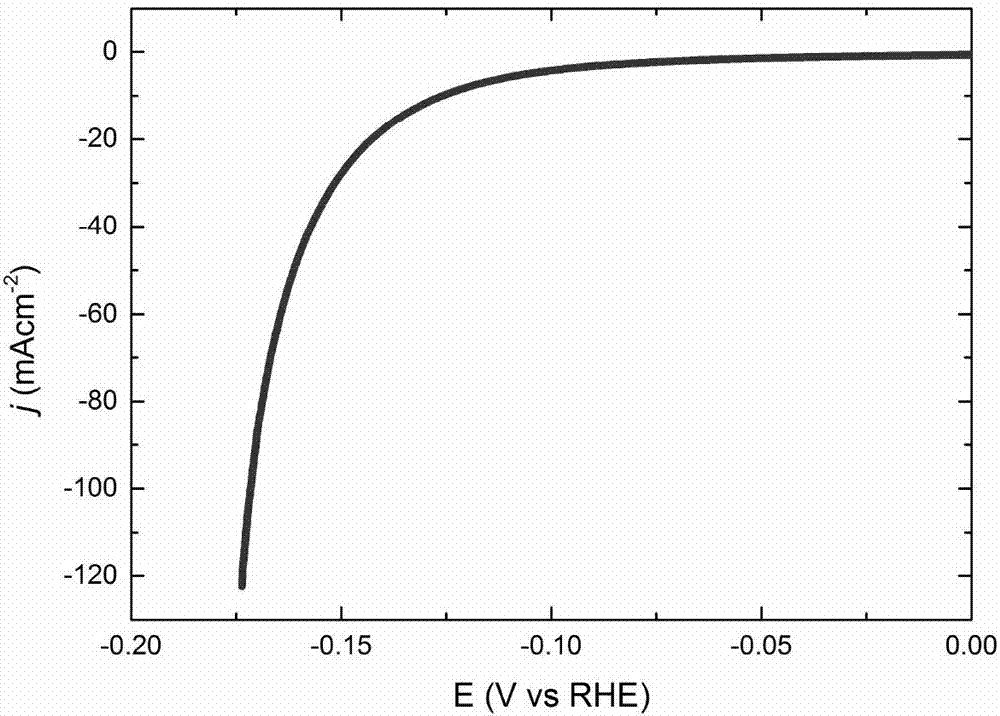

An electrocatalyst and hydrogen evolution reaction technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor stability, high overpotential, and low current density of electrocatalysts, and achieve low cost, many active sites, good electrolysis The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

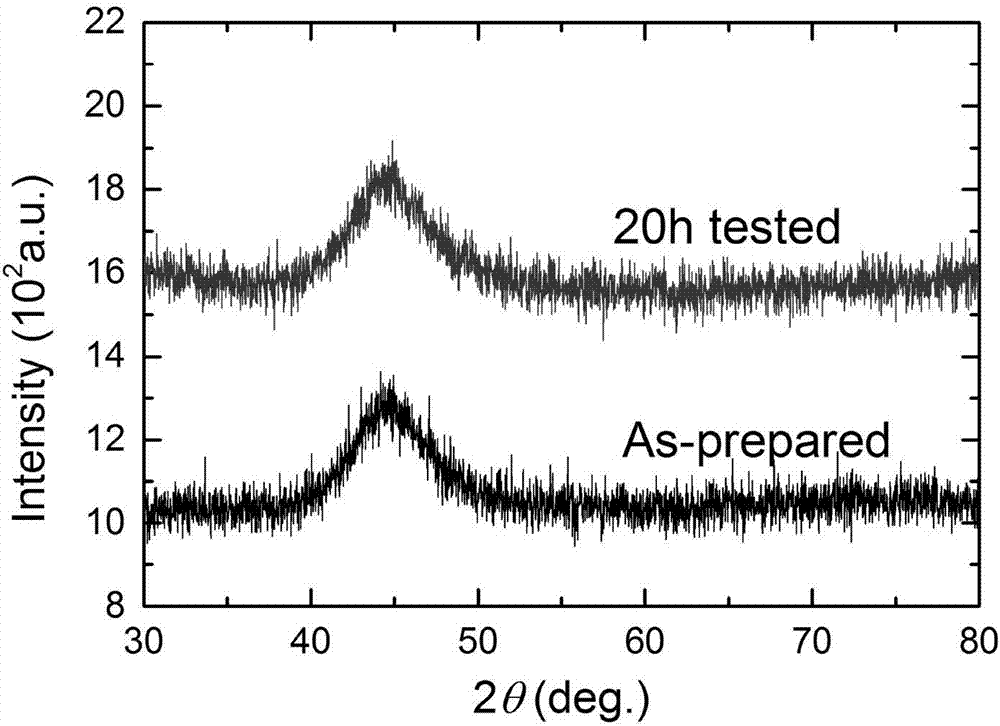

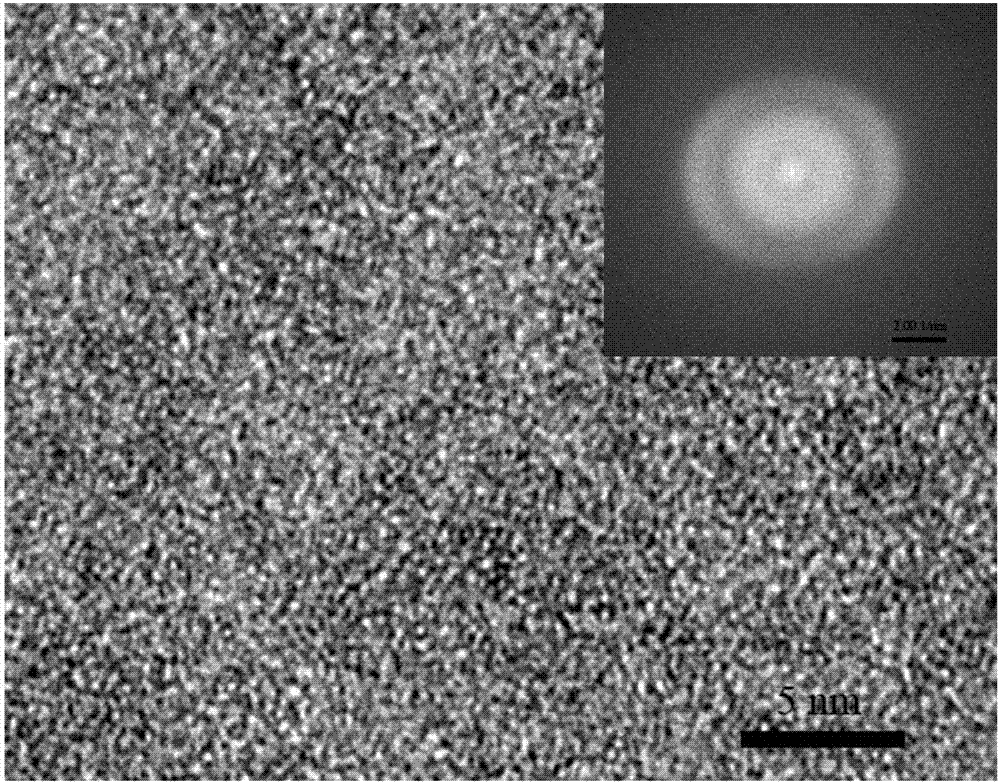

[0026] This embodiment prepares Fe according to the following steps 40 co 40 P 13 C 7 Amorphous alloy strip:

[0027] (1) Preparation of master alloy ingot

[0028] According to the nominal composition Fe 40 co 40 P 13 C 7 , Fe powder, Co powder with a purity of 99.9wt.%, P powder and C powder with a purity of not less than 99.00wt.% are batched, and then melted in a vacuum electric arc furnace under the protection of high-purity Ar gas, in order to ensure the alloy composition The composition of the master alloy is uniform, and the master alloy is repeatedly turned and smelted in the furnace for more than 4 times. During each smelting process, the ferrophosphorus and carbon powder are smelted as slowly as possible to prevent the volatilization of the raw materials due to excessive temperature. Finally, the master alloy ingot is obtained after cooling.

[0029] (2) High vacuum belt

[0030] The master alloy ingot obtained in step (1) is re-melted by induction heating,...

Embodiment 2

[0035] In this example, the Fe-Co-P-C based amorphous electrocatalyst was prepared in the same manner as in Example 1, the only difference being that the nominal composition of each raw material was changed to obtain strips with different compositions. The size parameters of the obtained samples are shown in Table 1. After characterization, each sample has an amorphous structure and has good electrocatalytic activity.

[0036] Table 1 Composition and size parameters of some samples of Fe-Co-P-C amorphous alloy strips

[0037] Sample composition

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com