Preparation method of novel metal organic complex fibers and derivative porous carbon fibers thereof

A porous carbon fiber, metal-organic technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, rayon manufacturing, etc., to achieve the effect of high yield, easy operation and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention discloses a method for preparing a metal-organic complex fiber and a porous carbon fiber derived therefrom, comprising the following steps:

[0037] Step a) using zinc nitrate hexahydrate and / or cobalt nitrate hexahydrate as a precursor, and adding dimethylimidazole to methanol respectively, then mixing the two solutions rapidly, reacting under magnetic stirring, centrifuging and washing the obtained product, Obtain metal-organic complex nanoparticles;

[0038] Step b) Dispersing metal-organic complex nanoparticles into N,N-dimethylformamide solution, then adding polyacrylonitrile, magnetic stirring to dissolve polyacrylonitrile, and obtaining milky white or purple electrospinning solution for later use;

[0039] Step c) preparing the electrospinning solution into metal-organic complex / polyacrylonitrile electrospun fibers by electrospinning technology, collecting them through a copper mesh, and then peeling off to obtain a metal-organic complex / polyacrylon...

Embodiment 1

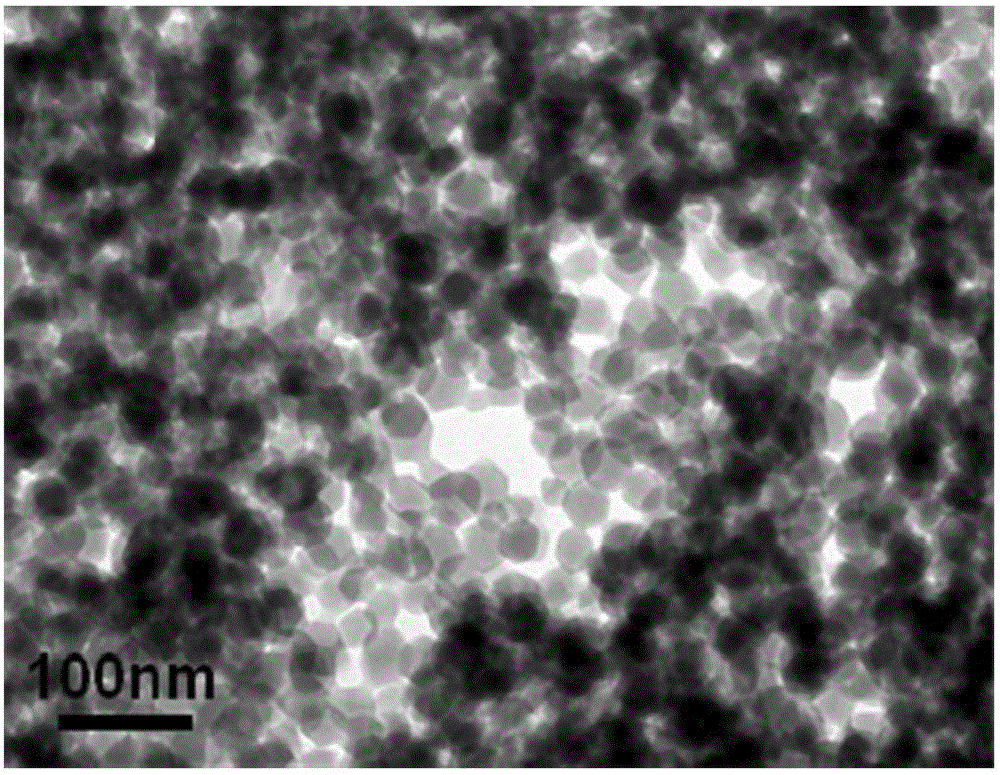

[0045] Dissolve 1.49g of zinc nitrate hexahydrate in 100mL of methanol, and dissolve 3.28g of dimethylimidazole in 100mL of methanol, then mix the two solutions, stir magnetically at 250rpm for 2h, and centrifuge the obtained product (10000rpm, 10min) and washing to obtain ZIF-8 nanoparticles.

[0046] Disperse ZIF-8 nanoparticles in 4mL of N,N-dimethylformamide, add 0.35g of polyacrylonitrile, and magnetically stir to dissolve. The obtained milky white solution is the electrospinning solution.

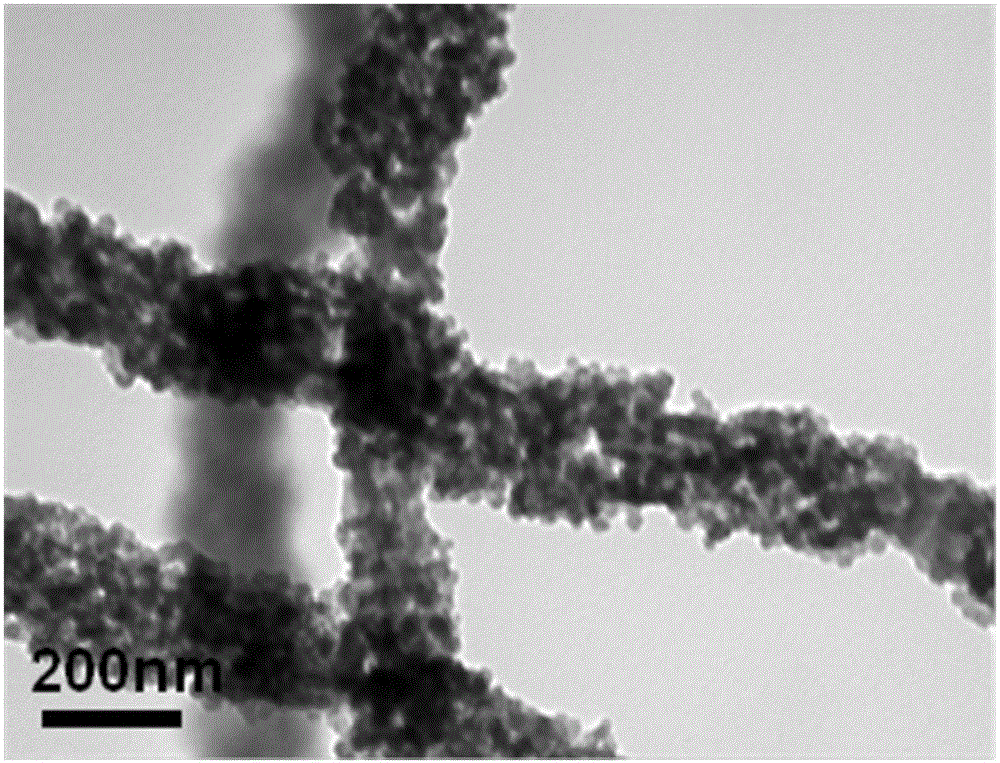

[0047] Transfer the electrospinning solution into a 10 mL syringe for electrospinning. The flow rate is set to 0.16mL / h, the voltage is 7.5KV, and the distance from the needle to the receiving screen is 12cm. The ZIF-8 nanoparticle / polyacrylonitrile electromimetic fiber can be obtained on the collection screen, and the ZIF-8 / polyacrylonitrile fiber film can be obtained after electrospinning for 1 hour.

[0048] The prepared ZIF-8 nanoparticles and electrospun fibers were observed by...

Embodiment 2

[0050] Dissolve 1.49g of zinc nitrate hexahydrate and 0.03g of cobalt nitrate hexahydrate in 100mL of methanol, and dissolve 3.28g of dimethylimidazole in 100mL of methanol, then mix the two solutions and stir magnetically at 250rpm for 2h, the obtained product Centrifuge (13000rpm, 10min) and wash to obtain bimetallic organic complex nanoparticles with a molar ratio of Zn:Co=100:2.

[0051] Disperse bimetallic organic complex nanoparticles in 4 mL of N,N-dimethylformamide, add 0.35 g of polyacrylonitrile, stir and dissolve with magnetic force, and the obtained purple solution is an electrospinning solution.

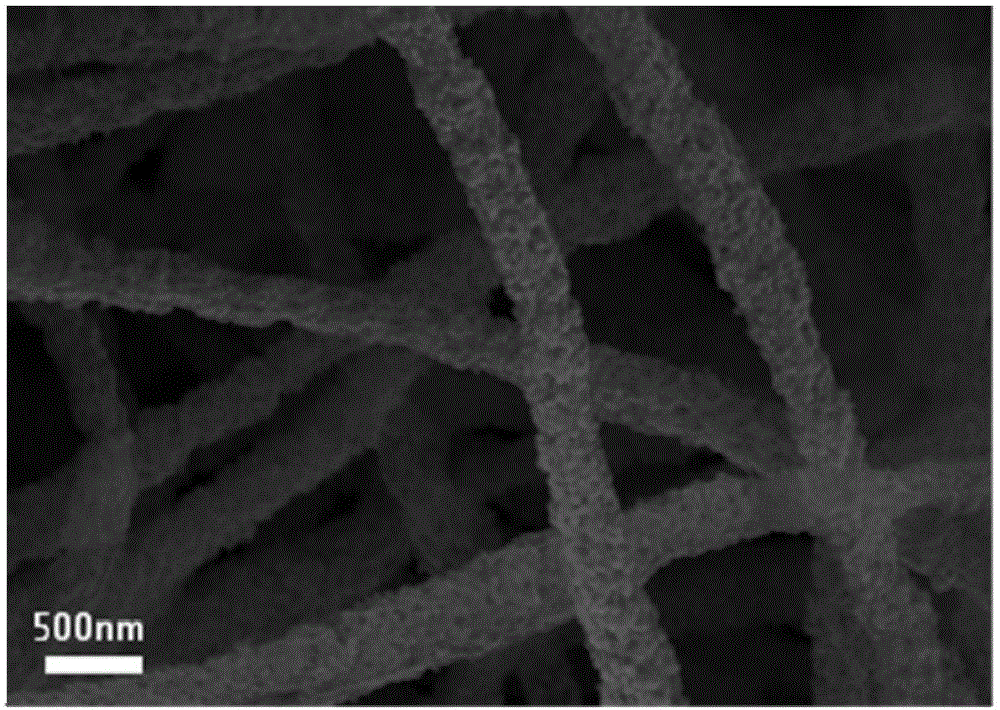

[0052] Transfer the electrospinning solution into a 10 mL syringe for electrospinning. The flow rate was set to 0.16mL / h, the voltage was 7.0KV, and the distance from the needle to the receiving screen was 12cm. Bimetallic organic complex nanoparticles / polyacrylonitrile electrospun fibers can be obtained on the collection screen, and bimetallic organic complex nanoparti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com