Method for treating high-concentration nitrate wastewater

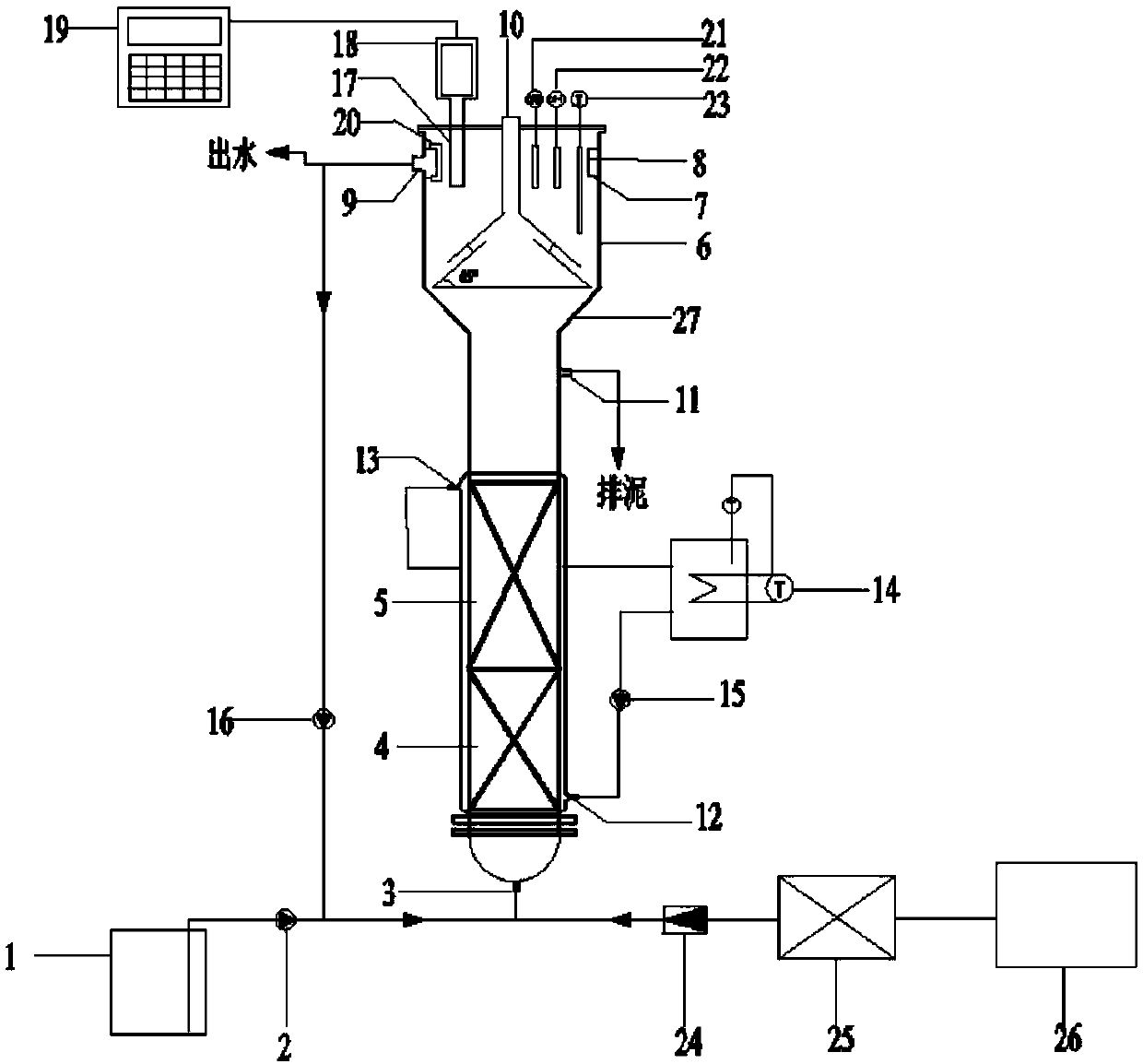

A nitrate and high-concentration technology, applied in anaerobic digestion treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of inability to deal with large-scale wastewater, secondary pollution of zinc powder, high price, etc., and achieve high efficiency Substrate mass transfer rate and wastewater treatment efficiency, prevent sludge from clogging the filter, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The concentration of nitrate in the industrial wastewater treated in this embodiment is 13766mg / L (NO 3 - N concentration is 3108mg / L), COD concentration is 2430mg / L, and pH is 0.5.

[0058] First, the industrial wastewater is pretreated, including:

[0059] (1) Add carbon source (methanol) to industrial wastewater to make COD 11344mg / L, COD:NO 3 The mass concentration ratio of -N is 3.65;

[0060] (2) Add nitrogen nutrient salt (ammonia or urea), phosphorus nutrient salt (KH) to the waste water that step (1) obtains 2 PO 4 or Na 3 PO 4 ) are respectively so that in terms of N elements, the concentration of N is 142mg / L, in terms of P elements, the concentration of P is 28mg / L, and the ratio of the mass concentration of COD:N:P is 400:5:1;

[0061] (3) adding alkali (NaOH) to the waste water obtained in step (2) to adjust the pH of the waste water to 2 to obtain pretreated waste water.

[0062] The pretreated waste water is passed into the anoxic expanded bed re...

Embodiment 2

[0066] The industrial waste water nitrate content of processing in the present embodiment is 29178mg / L (NO 3 - The N concentration is 6588 mg / L), the COD concentration is 4300 mg / L, and the pH is 0.3.

[0067] First, the industrial wastewater is pretreated, including:

[0068] (1) supplement carbon source (methanol) to make COD be 26020mg / L in described industrial waste water, COD:NO 3 The mass concentration ratio of -N is 3.9;

[0069] (2) Add nitrogen nutrient salt (ammonia or urea), phosphorus nutrient salt (KH) to the wastewater obtained in step (1) 2 PO 4 or Na 3 PO 4 ) are respectively to make the concentration of N in terms of N elements be 435mg / L, in terms of P elements, the concentration of P is 87mg / L, and the ratio of the mass concentration of COD:N:P is 299:5:1;

[0070] (3) adding alkali (NaOH) to the wastewater in step (2) to adjust the pH of the influent to 2.2 to obtain pretreated wastewater.

[0071] The pretreated waste water is fed into the anoxic e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com