Core-shell structure conductive microsphere with adjustable specific gravity as well as preparation method and application of core-shell structure conductive microsphere

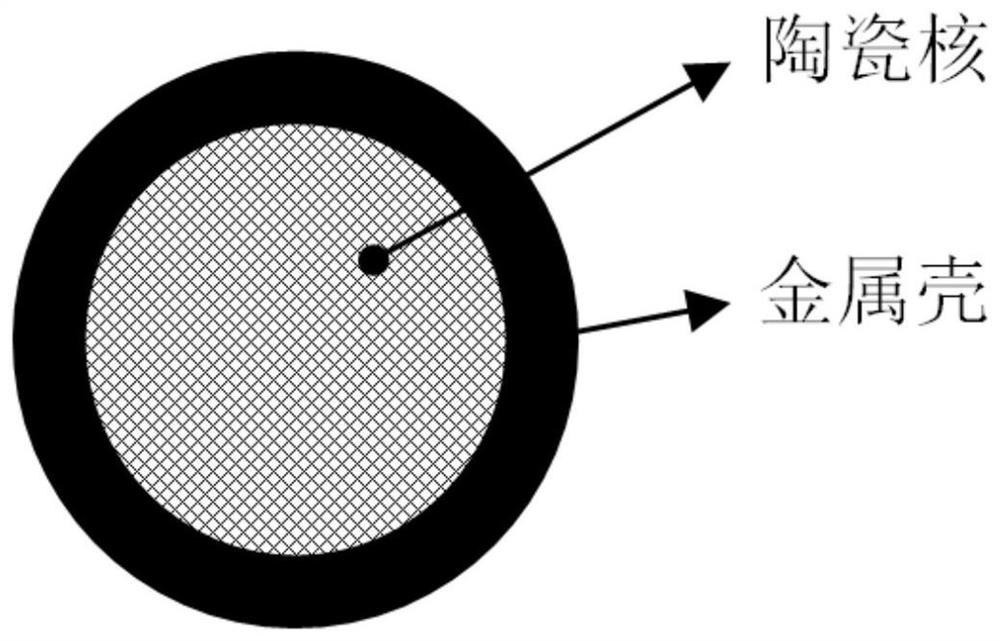

A core-shell structure and microsphere technology, applied in the field of materials, can solve the problems of low electroplating yield, poor conductive medium effect, large size of stainless steel balls, etc., and achieve the effects of dense core-shell structure, densification, and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

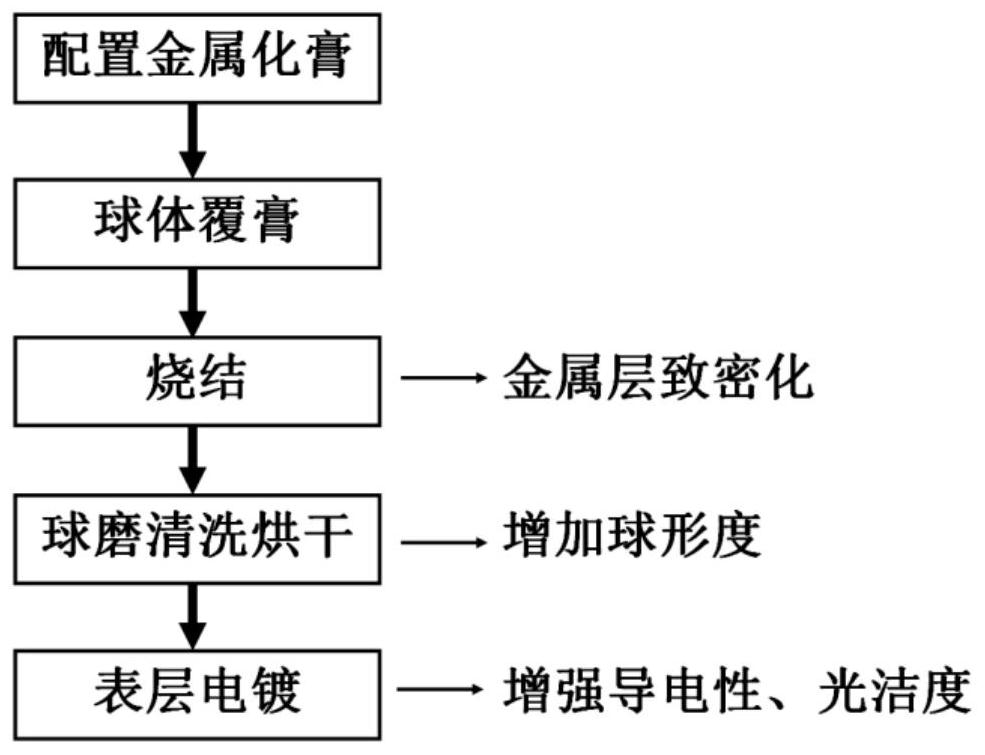

[0080] refer to figure 1 , a method for preparing conductive microspheres with a core-shell structure with adjustable specific gravity, comprising the following steps:

[0081] (1) Prepare metallization paste: molybdenum powder: glass phase additive (mixed with manganese powder, silicon oxide powder and aluminum oxide powder according to the mass ratio of 3:3:4) = 80:20 for batching according to mass percentage; Put it into the agate ball mill tank of the planetary ball mill for ball milling, the ball-to-material ratio is 1:1, the diameter of the agate ball is about 5mm, the revolution is set at 100r / min, and the rotation is set at 200r / min; the powder is discharged after ball milling for 50h; add nitrocellulose solution (with Butyl acetate is used as a solvent, the concentration of nitrocellulose is 2wt%), the mass ratio of metal powder and nitrocellulose solution is 3:1, put into a roller mill, and carry out mixed grinding for 50h at a speed of 120r / min to obtain molybdenum ...

Embodiment 2

[0100] (1) Prepare metallization paste: molybdenum powder: glass phase additive (mixed with manganese powder, silicon oxide powder and aluminum oxide powder according to the mass ratio of 3:3:4) = 80:20 for batching according to mass percentage; Enter the agate ball mill tank of the planetary ball mill for ball milling, the ball-to-material ratio is 1:1, the diameter of the agate ball is about 5mm, the revolution is set at 100r / min, and the rotation is set at 200r / min; the powder is discharged after ball milling for 30h; add nitrocellulose solution (with Butyl acetate is used as a solvent, the concentration of nitrocellulose is 2wt%), the mass ratio of metal powder and nitrocellulose solution is 3:1, put into a roller mill, and carry out mixed grinding for 30 hours at a speed of 120r / min to obtain molybdenum metallization paste;

[0101] (2) Select 95 alumina ceramic microsphere powders with a diameter of about 1800 μm (according to the gas replacement method, the specific gra...

Embodiment 3

[0109] (1) Preparation of metallization paste: molybdenum powder: glass phase additive (mixed from manganese powder, silicon oxide powder and aluminum oxide powder according to the mass ratio of 3:3:4) = 70:30 by mass percentage; Put it into the agate ball mill tank of the planetary ball mill for ball milling, the ball-to-material ratio is 1:1, the diameter of the agate ball is about 5mm, the revolution is set at 100r / min, and the rotation is set at 200r / min; the powder is discharged after ball milling for 50h; add nitrocellulose solution (with Butyl acetate is used as a solvent, the concentration of nitrocellulose is 2wt%), the mass ratio of metal powder and nitrocellulose solution is 1:1, put into a roller mill, and carry out mixed grinding at 120r / min for 50h to obtain molybdenum metal ointment;

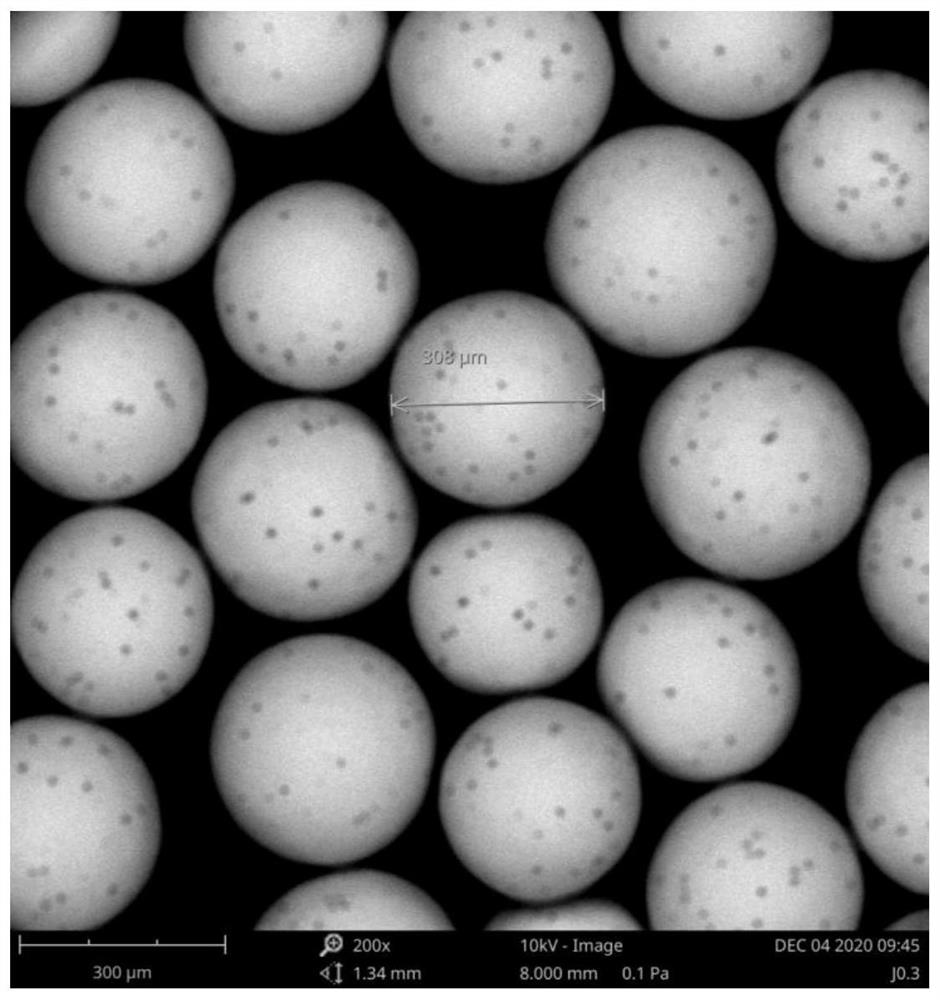

[0110] (2) Select zirconia ceramic microsphere powder with a diameter of about 50 μm (the composition is ZrO 2 : Y 2 o 3 =95:5) (according to the gas replacement method, its sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com