A kind of silicon carbide coating and preparation method thereof

A silicon carbide coating and coating technology, applied in the field of silicon carbide coating and its preparation, can solve the problems of high preparation cost, increase of coating cycle, anti-oxidation coating damage, etc., reduce the preparation cycle and simplify the preparation process , the effect of rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

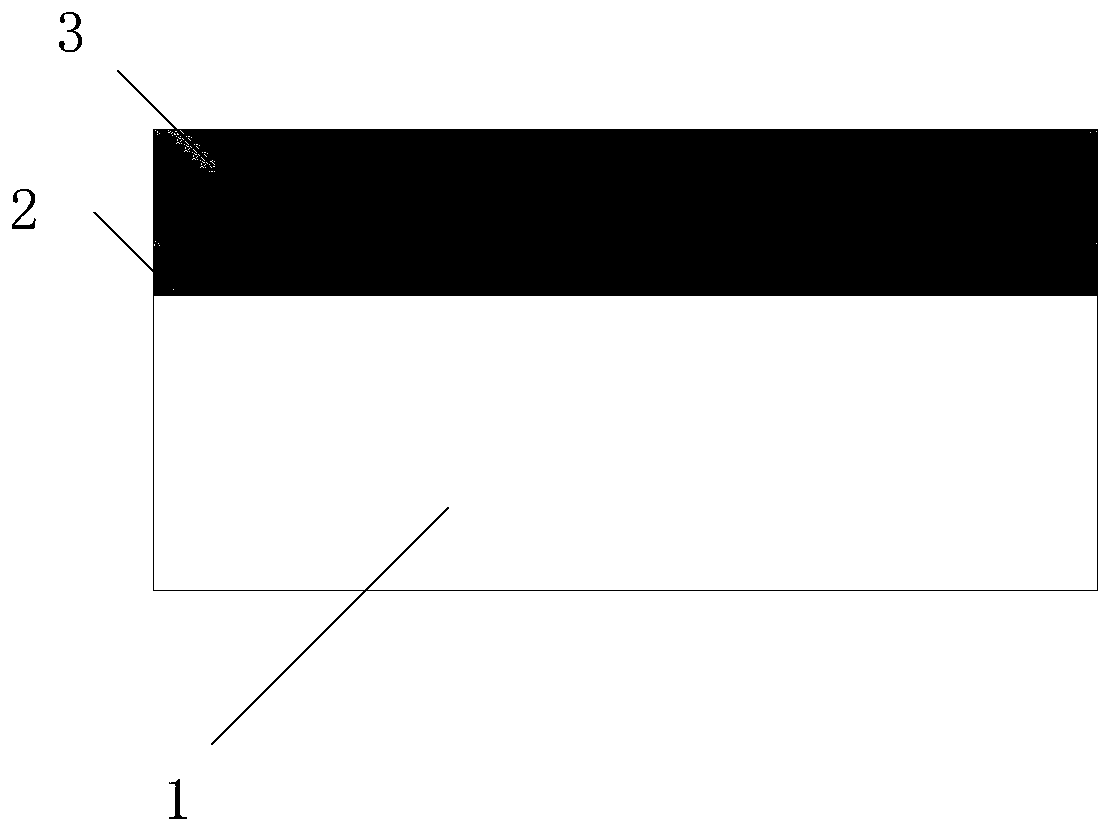

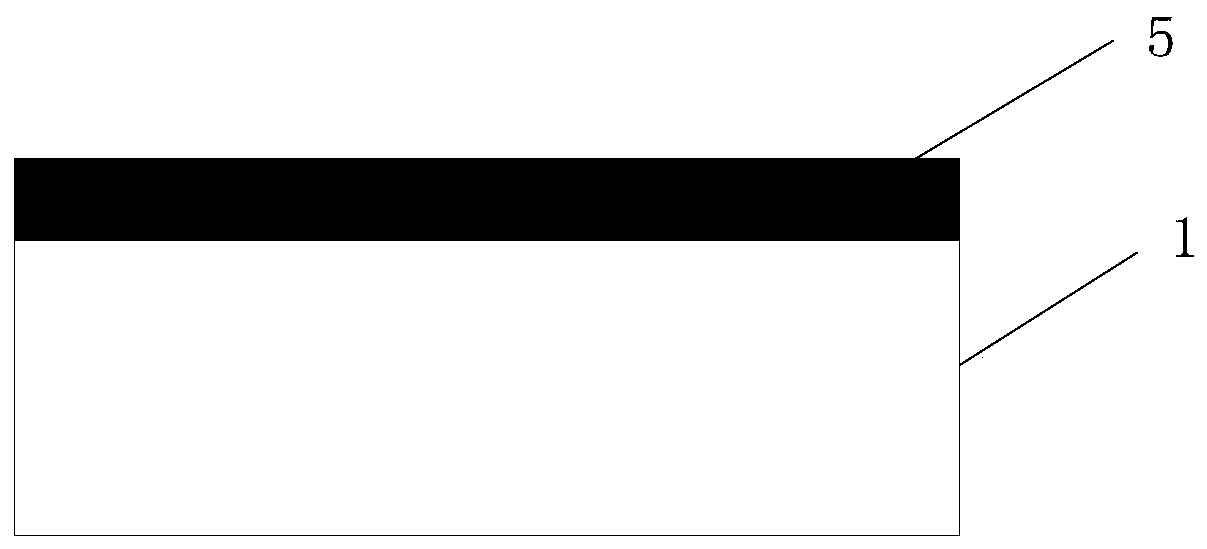

[0030] The embodiment of the present invention provides a method for preparing a silicon carbide coating, comprising the following steps:

[0031] Step (1): Prepare the first coating slurry and the second coating slurry respectively, wherein the raw material of the first coating slurry includes phenolic aldehyde with a mass ratio of 3:(3-5):(0.5-1.5) Resin, Si powder and SiC powder, the second coating slurry is siliconized slurry;

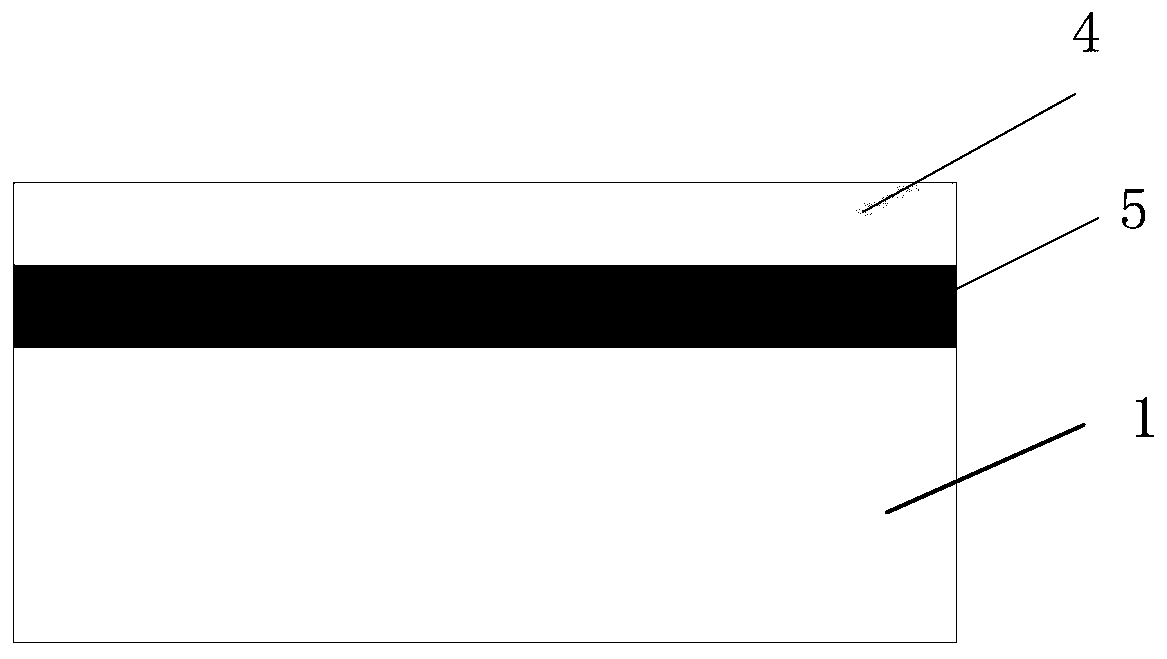

[0032] Specifically, the silicidation slurry can be the coating slurry used in the traditional coating and sintering silicon carbide coating preparation process; in the embodiment of the present invention, the raw material of the silicidation slurry includes a mass ratio of 3:(2 ~4): (1~3) silicone resin, Si powder and SiC powder. The silicidation slurry formula provided by the embodiment of the present invention can form a coupled coating layer in combination with the first coating slurry formula, and provide an additional silicon source for the ...

Embodiment 1

[0052](1) Take each material according to the mass ratio of phenolic resin: Si powder: SiC powder: ethanol=3:4:0.5:3.5, mix the weighed phenolic resin, Si powder and SiC powder, and use the weighed ethanol Regulate its viscosity to the degree suitable for coating to form the main layer slurry; take each material according to the mass ratio of silicone resin: Si powder: SiC powder: toluene=3:3:1:3, and the silicone resin that has been weighed , Si powder and SiC powder are mixed evenly, and the viscosity is adjusted to a level suitable for coating with toluene weighed to form a siliconized slurry.

[0053] (2) With a density of 1.8g / cm 3 The carbon / carbon composite material is used as the substrate, the main layer slurry is coated on the surface of the substrate, and then cured to form an inner coating layer with a thickness of about 100 μm; the siliconized slurry is coated and cured on the surface of the inner coating layer twice to form An outer cladding with a thickness of ...

Embodiment 2

[0060] (1) Take each material according to the mass ratio of phenolic resin: Si powder: SiC powder: acetone=3:3:1:4, mix the weighed phenolic resin, Si powder and SiC powder, and use the weighed acetone Regulate its viscosity to the degree suitable for coating to obtain the main layer slurry; take each material according to the mass ratio of silicone resin: Si powder: SiC powder: ethanol = 3:2:1:2, and weigh the silicone resin , Si powder and SiC powder are mixed evenly, and the viscosity is adjusted to a level suitable for coating with weighed ethanol to obtain the main slurry.

[0061] (2) With a density of 1.5g / cm 3 The carbon / silicon carbide composite material is used as the substrate, and the main layer slurry is coated and cured on the surface of the substrate twice to form an inner coating layer with a thickness of about 200 μm; the siliconized slurry is coated and cured on the inner coating layer twice On the surface, an outer cladding layer with a thickness of about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com