Siliconized graphite and preparation method of siliconized graphite

A technology of siliconized graphite and siliconized graphite, which is applied in the field of siliconized graphite preparation technology, can solve problems such as low efficiency, poor bonding strength, and easy falling off of the siliconized layer, and achieve high density, good acid and alkali resistance, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

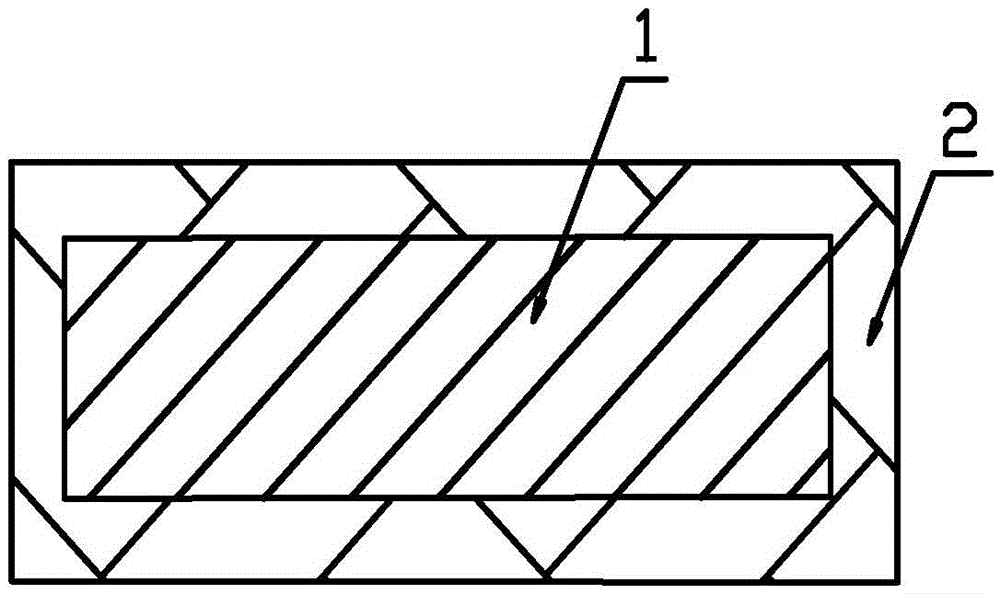

[0025] Such as figure 1 As shown, a silicided graphite has a siliconized graphite layer 1 inside and a silicide layer 2 on its surface.

[0026] The preparation method of described graphite silicide is:

[0027] The graphite boat and graphite base material equipped with silicon source are placed in vacuum siliconization equipment, and the vacuum degree inside the siliconization equipment is 10 -3 Pa, from room temperature to 1200°C, the heating rate is 10°C / min. At this time, the silicon source is converted into silicon liquid, and the graphite base material is put into the silicon liquid with a manipulator. At 1200°C, silicification is carried out at a constant temperature for 6 hours. After the silicide reaction is completed, cool to room temperature to obtain the silicided graphite.

[0028] The ratio by weight of the graphite base material to the silicon liquid is 20:40, the shape of the graphite base material is set as a cylinder, and the purity of the silicon liquid is...

Embodiment 2

[0032] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0033] The graphite boat and graphite base material equipped with silicon source are placed in vacuum siliconization equipment, and the vacuum degree inside the siliconization equipment is 10 -3 Pa, the heating rate is 10°C / min. After the temperature rises from room temperature to 1200°C, put the graphite base material into the silicon liquid with a manipulator, and silicify at a constant temperature for 8 hours at 1200°C. After the silicification reaction is completed, cool to room temperature to obtain The silicided graphite.

[0034] The weight ratio of graphite base material to silicon liquid is 20:40.

[0035] The silicified graphite properties prepared by the method are as follows:

[0036] Silicide layer 2 has a thickness of 0.6mm and a bulk density of 2.38g·cm -3 , hardness 3050Hv, compressive strength 305MPa, flexural strength 155MPa, tensile strength 55MPa, t...

Embodiment 3

[0038] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0039] The graphite boat and graphite base material equipped with silicon source are placed in vacuum siliconization equipment, and the vacuum degree inside the siliconization equipment is 10 -3 Pa, the heating rate is 10°C / min. After the temperature rises from room temperature to 1400°C, put the graphite base material into the silicon liquid with a manipulator, and silicify at a constant temperature for 6 hours at 1400°C. After the silicification reaction is completed, cool to room temperature to obtain The silicided graphite.

[0040] The weight ratio of the graphite base material to the silicon liquid is 20:40, and the shape of the graphite base material is a cone.

[0041] The silicified graphite properties prepared by the method are as follows:

[0042] Silicide layer 2 has a thickness of 0.7mm and a bulk density of 2.39g cm -3 , hardness 3000Hv, compressive stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com