Polyamide hollow fiber composite separation membrane and preparation method

A fiber composite and polyamide technology, which is applied in the field of polyamide hollow fiber composite separation membrane and its preparation, can solve the problem of continuous production of hollow fiber composite separation membrane, uneven thickness of separation layer of hollow fiber composite separation membrane, and solution viscosity Small and other problems, to achieve the effect of improving membrane separation performance, improving membrane strength and operation stability, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare a polyamide hollow fiber composite reverse osmosis membrane, the specific method is as follows:

[0042] 1) Mixing: mix polyvinylidene fluoride with a mass fraction of 20%, diphenyl carbonate with a mass fraction of 79.9%, and trimesoyl chloride with a mass fraction of 0.1% as a casting solution, and pass through a twin-screw extruder Mix well at 220°C;

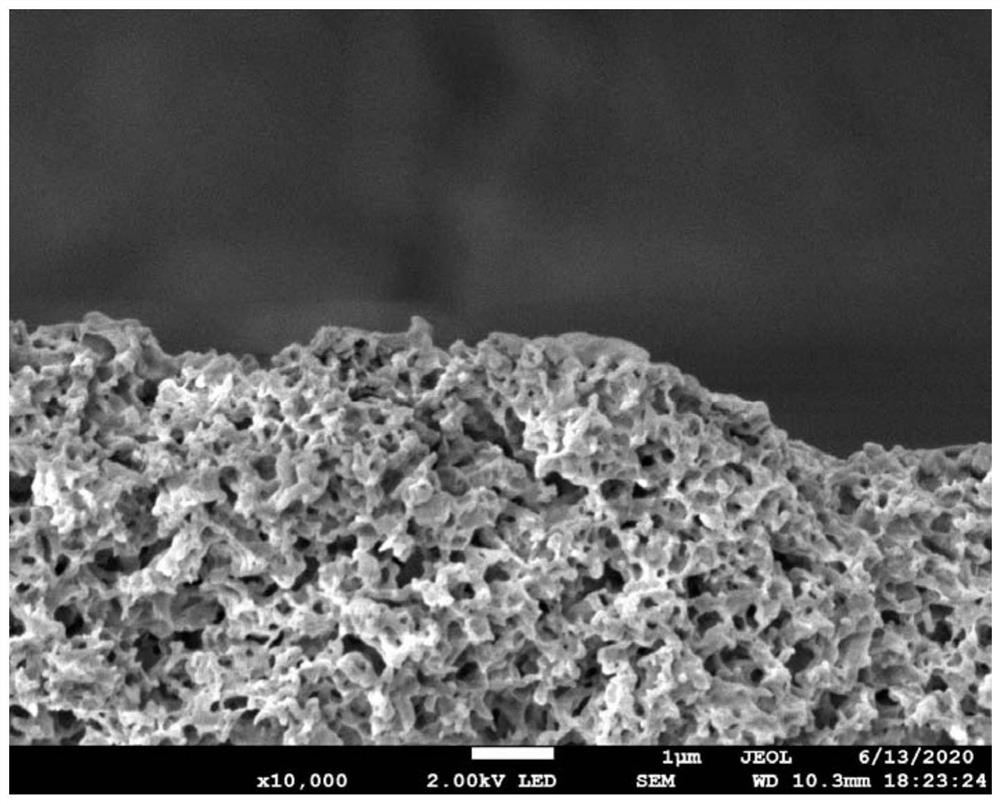

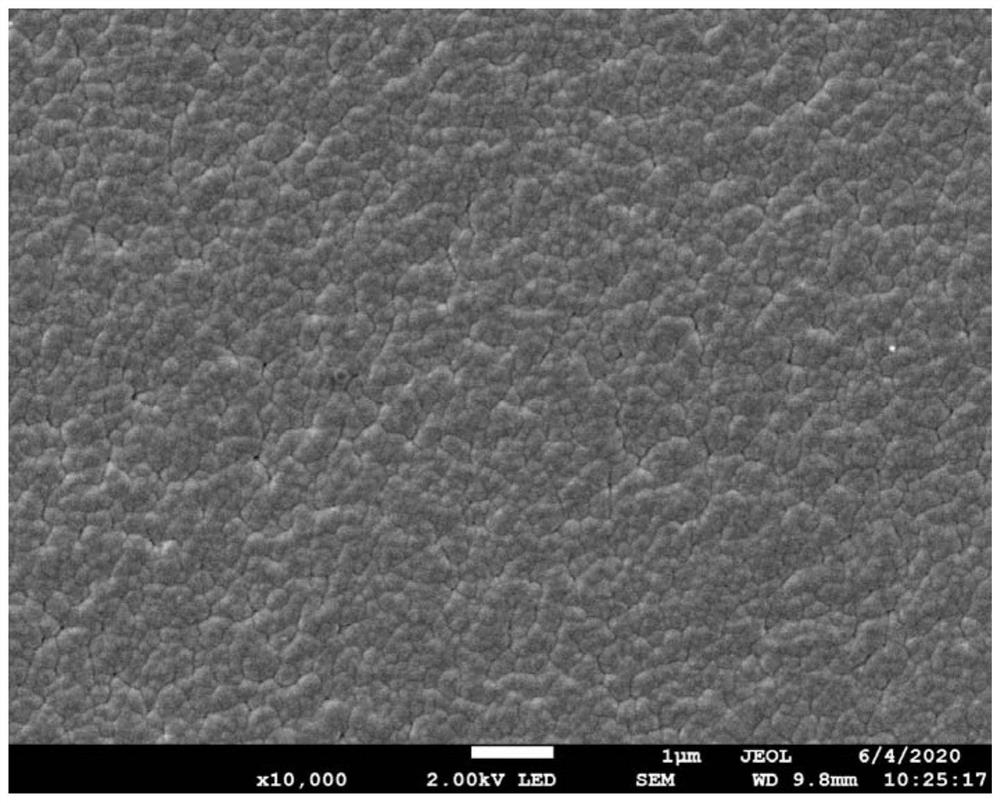

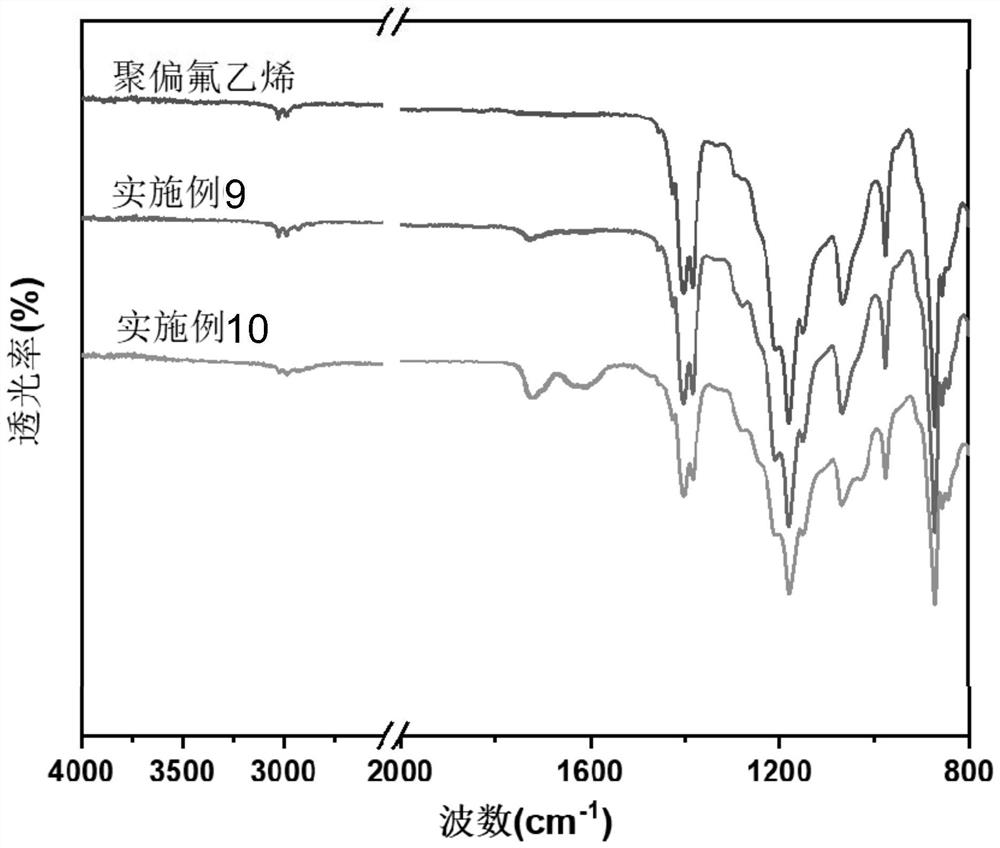

[0043] 2) Composite membrane preparation: Extrude the casting solution in step 1) to the spinneret with a twin-screw extruder to form a hollow fiber membrane, and enter the temperature after passing through the air section at room temperature with a temperature of 25°C and a concentration of 2.0% by weight. Cool the water bath in the m-phenylenediamine aqueous solution for 120s. While solidifying and forming a film, trimesoyl chloride and the m-phenylenediamine in the water bath undergo interfacial polymerization to form a polyamide layer. Dry at 80°C for 10 minutes to obtain polyvinylidene fluoride-containing ...

Embodiment 2

[0046] A kind of polyamide hollow fiber composite reverse osmosis membrane is prepared, the mass fraction of polyvinylidene fluoride in the 1) mixing step in embodiment 1 is increased to 40%, and diphenyl carbonate mass fraction is reduced to 59.9%, and other conditions are not changed. Change.

Embodiment 3

[0048] To prepare a polyamide hollow fiber composite reverse osmosis membrane, the concentration of phenylenediamine in the 2) composite membrane preparation step in Example 1 was increased to 5% by weight, and other conditions remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com