Edge hydroxylation modification method for hexagonal layered boron nitride

A technology of boron nitride and hydroxylation, which is applied in the field of edge hydroxylation modification of hexagonal layered boron nitride, can solve the problems of high thermal conductivity, affecting the mean free path of phonons, and unfavorable thermal conductivity, etc., and achieves simple operation process , weaken the tendency of secondary agglomeration into large particles, and reduce the effect of interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

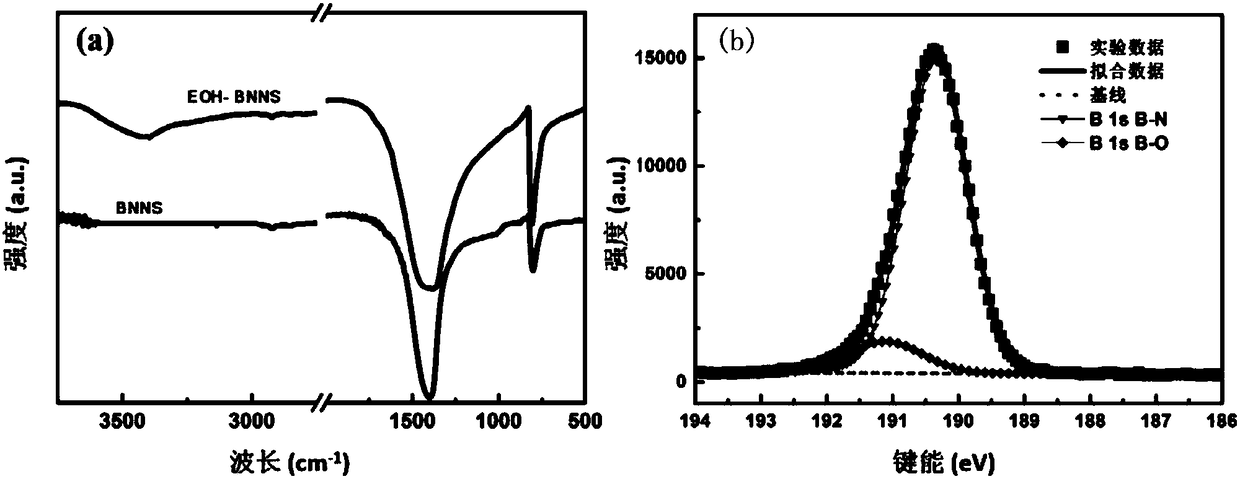

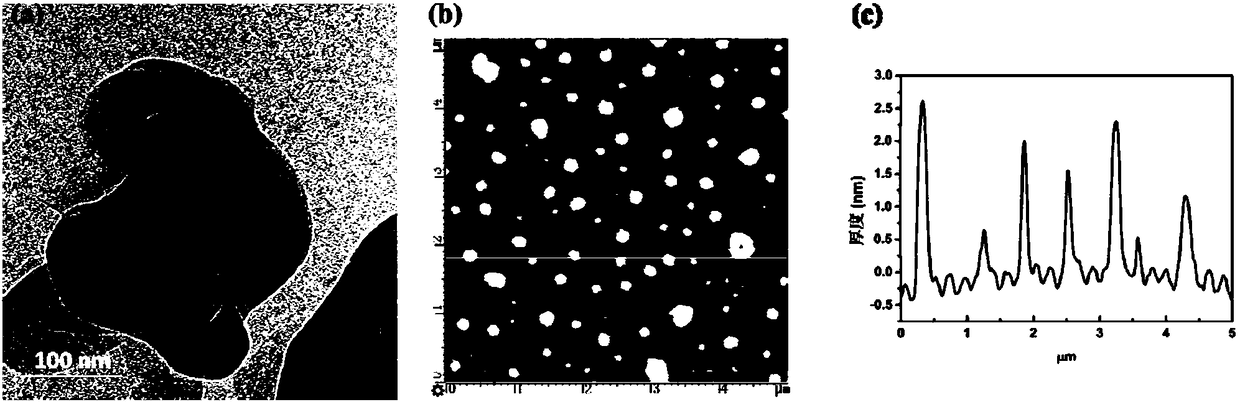

[0027] (1) Edge hydroxylation modification of hexagonal layered boron nitride: add urea and deionized water to hexagonal layered boron nitride, and then ball mill at room temperature for 2 to 12 hours to obtain completely hydroxylated modified hexagonal layered nitrogen Boron oxide; wherein, the dosage ratio of hexagonal layered boron nitride, urea and deionized water is 500-20000mg: 30-60g: 12-24mL;

[0028] (2) post-treatment: the modified hexagonal layered boron nitride obtained in step (1) is diluted with deionized water, and the diluted boron nitride solution is repeatedly diluted-ultrasonic dispersion-centrifugal treatment at room temperature, Remove excess urea and impurities; then take off the lower layer and precipitate and dry to obtain hexagonal layered boron nitride modified by edge hydroxylation.

[0029] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate...

Embodiment 1

[0031] Hexagonal layered boron nitride (EOH-BNNS) modified by edge hydroxylation was prepared by the following steps:

[0032] Step 1: Edge hydroxylation modification of BNNS:

[0033] Add 30g of urea and 12mL of deionized water to 500mg of BNNS powder, and then use a planetary ball mill at room temperature for 2 hours, specifically, every 30 minutes of ball milling with an interval of 10 minutes, and a total of 2 hours of ball milling;

[0034] Step 2: Repeated washing with deionized water to remove excess urea and impurities:

[0035] Dilute the product obtained in step (1) with 1000mL of deionized water, disperse the diluted boron nitride solution at room temperature and at an ultrasonic power of 100W for 30min, and then centrifuge. For 15min, after centrifugation, remove the part of the precipitate;

[0036] Step 3: Wash and dry EOH-BNNS:

[0037] Dilute the product obtained by centrifugation with 1000 mL of deionized water again, ultrasonically disperse evenly for 30 m...

Embodiment 2

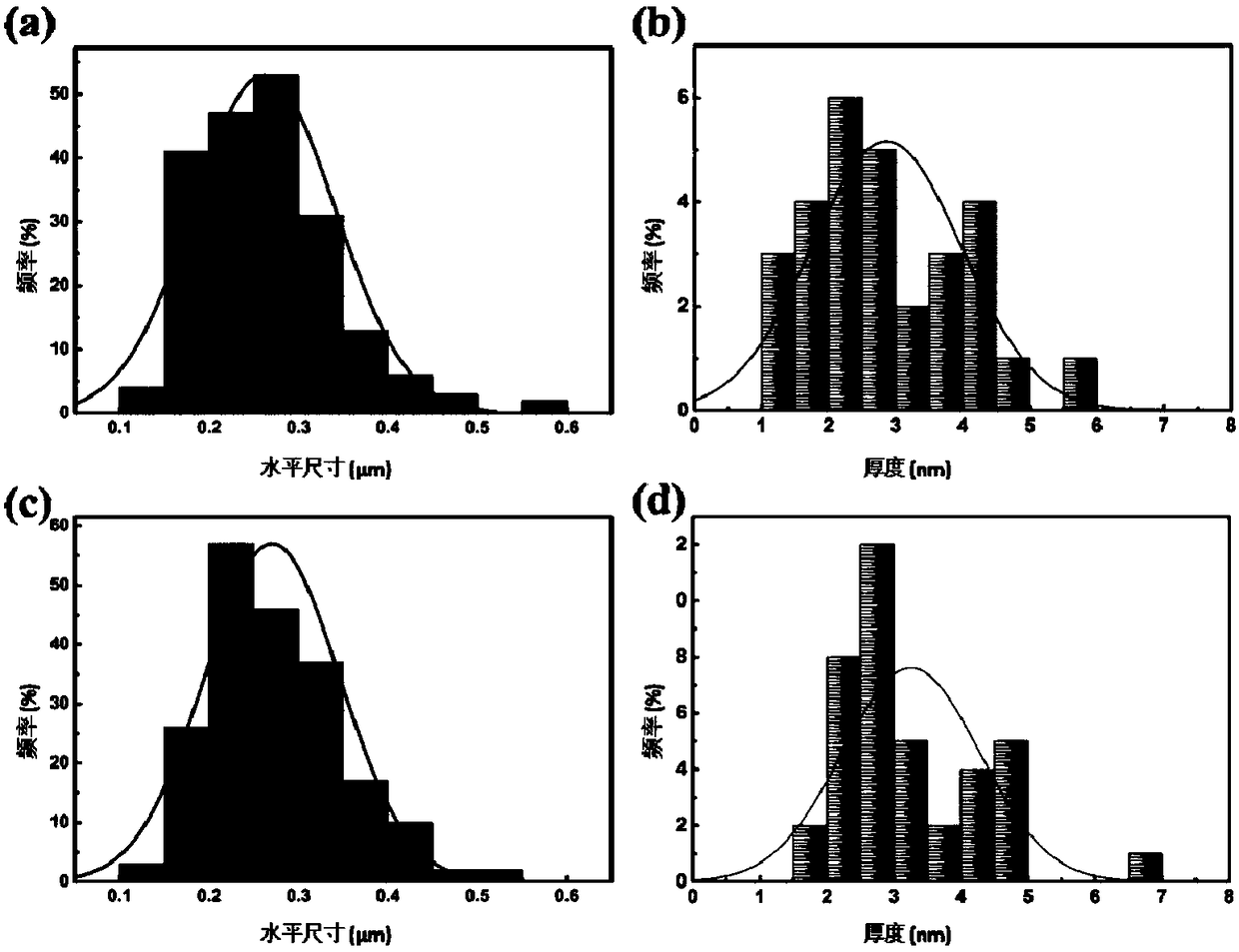

[0040] The EOH-BNNS modified by edge hydroxylation was prepared by the following steps:

[0041] Step 1: Edge hydroxylation modification of hexagonal layered boron nitride:

[0042]Add 45 g of urea and 18 mL of deionized water to 750 mg of hexagonal boron nitride powder, and then use a planetary ball mill at room temperature for 12 hours. Specifically, every 30 minutes of ball milling is performed at intervals of 10 minutes, for a total of 12 hours of ball milling.

[0043] Step 2: Repeated washing with deionized water to remove excess urea and impurities:

[0044] Dilute the product obtained in step (1) with 1000mL of deionized water, disperse the diluted boron nitride solution at room temperature and at an ultrasonic power of 100W for 30min, and then centrifuge. After 15 minutes, the lower part of the centrifugation ends.

[0045] Step 3: Wash and dry EOH-BNNS:

[0046] Dilute the product obtained by centrifugation with 1000 mL of deionized water again, ultrasonically dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com