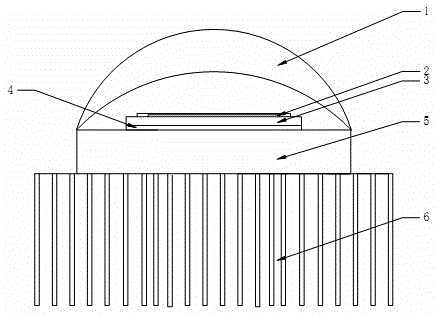

Heat dissipation interface material used for packaging of high-power LED (light emitting diode) lamp and preparation method thereof

A technology of LED lamps and interface materials, which is applied in the cooling/heating devices of lighting devices, lighting and heating equipment, chemical instruments and methods, etc. Tiling and other issues, to achieve the effect of miniaturization improvement, avoiding contact gap, and reducing interface contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) 0.05 parts by weight of silane coupling agent KH-550 was dissolved in 95wt% ethanol to prepare a 25wt% solution. Stir continuously. After dissolving, add 0.5 parts by weight of graphene microchips and place in a 60°C water bath , sonicated for about 4 hours. After the solvent is evaporated, put it in an evaporating dish, put it into an oven, dry it at 120°C for 10 hours, and then dry it at 150°C for 2 hours to obtain functionalized graphene microchips for use;

[0019] 2) Repeatedly knead 100 parts by weight of component A silicone resin with the above-mentioned 0.5 parts by weight of functionalized graphene and 20 parts by weight of simethicone in a double-roll mill until uniform. Then add 2.0 parts by weight of B-component silicone resin, after mixing evenly, collect the mixture on the roller shaft, place it in a mold with a polyester film in the inner cavity, and press it into a tablet in a flat vulcanizer, the condition is : The mold temperature is 120°C, the pr...

Embodiment 2

[0023] 1) 0.1 parts by weight of silane coupling agent KH-550 was dissolved in 95wt% ethanol to prepare a 25wt% solution. Stir continuously. After dissolving, add 1.0 parts by weight of graphene microchips and place in a 60°C water bath , sonicated for about 4 hours. After the solvent is evaporated, put it in an evaporating dish, put it into an oven, dry it at 120°C for 10 hours, and then dry it at 150°C for 2 hours to obtain functionalized graphene microchips for use;

[0024] 2) Repeatedly knead 100 parts by weight of component A silicone resin with the above-mentioned 1.0 parts by weight of functionalized graphene and 20 parts by weight of simethicone in a double-roll mill until uniform. Then add 2.0 parts by weight of B-component silicone resin, after mixing evenly, collect the mixture on the roller shaft, place it in a mold with a polyester film in the inner cavity, and press it into a tablet in a flat vulcanizer, the condition is : The mold temperature is 120°C, the pre...

Embodiment 3

[0027] 1) 0.15 parts by weight of silane coupling agent KH-550 was dissolved in 95wt% ethanol to prepare a 25wt% solution. Stir continuously. After dissolving, add 1.5 parts by weight of graphene microchips and place in a 60°C water bath , sonicated for about 4 hours. After the solvent has evaporated, place it in an evaporating dish, put it in an oven, and dry it at 120°C for 10 hours, and then dry it at 150°C for 2 hours to obtain functionalized graphene microchips for use;

[0028]2) Repeatedly knead 100 parts by weight of component A silicone resin with the above-mentioned 1.5 parts by weight of functionalized graphene and 25 parts by weight of simethicone in a double-roll mill for about 40 minutes until uniform. Then add 2.0 parts by weight of B-component silicone resin, after mixing evenly, collect the mixture on the roller shaft, place it in a mold with a polyester film in the inner cavity, and press it into a tablet in a flat vulcanizer, the condition is : The mold tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com