LED fluorescent lamp

A technology of LED fluorescent lamps and blue light chips, applied in the field of LED fluorescent tubes, can solve problems such as heat can not be exported in time, voltage is difficult to light up, circuit board deformation, etc., to avoid LED brightness attenuation, improve brightness and color rendering, and avoid contact Effect of Face Gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

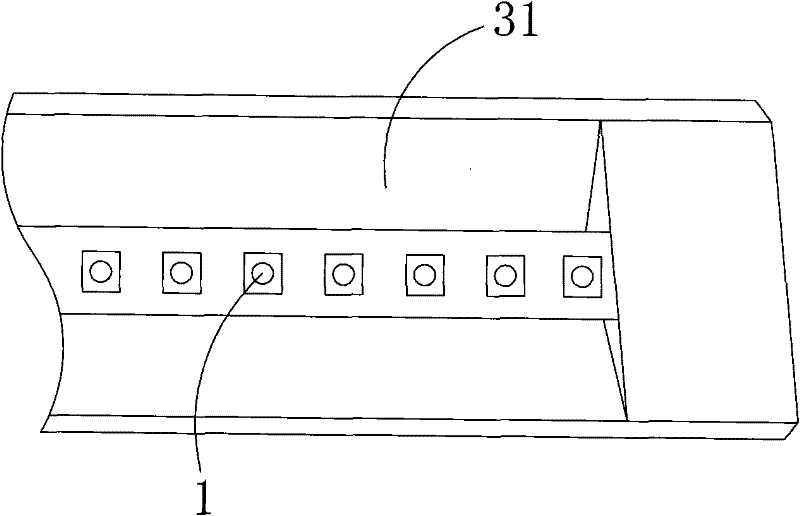

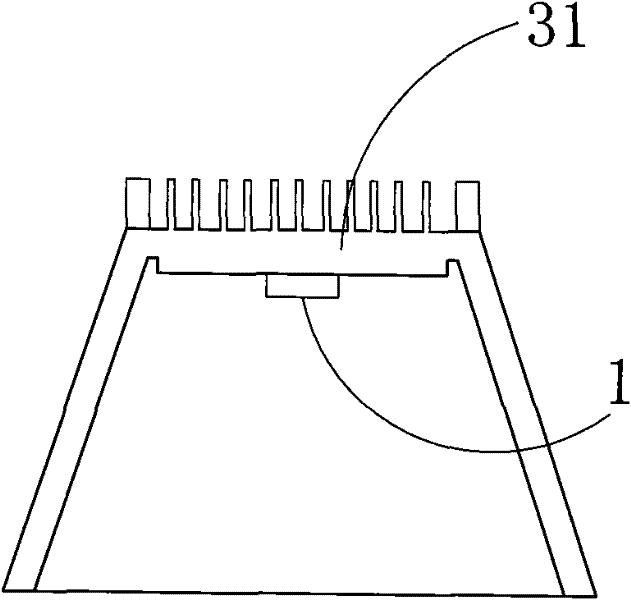

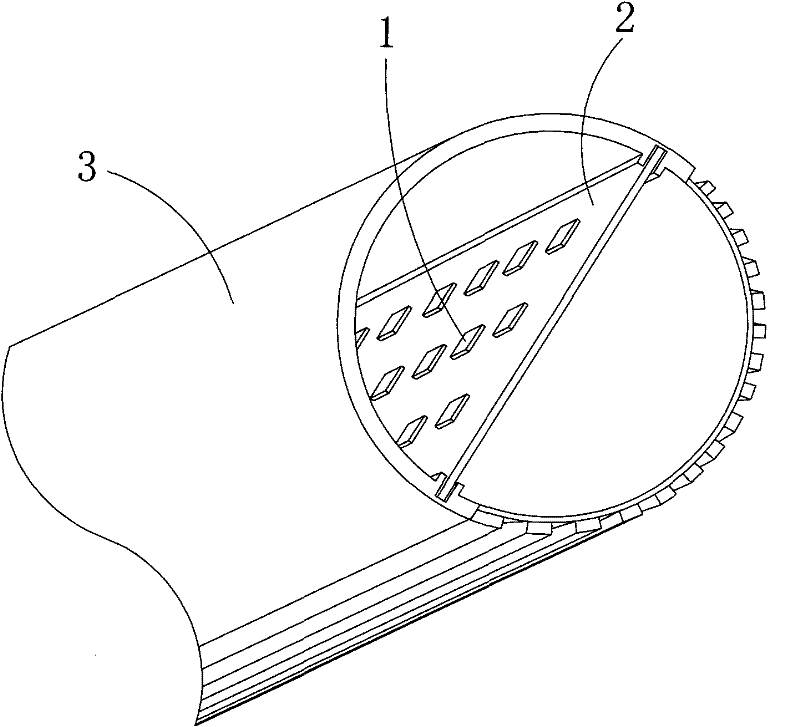

[0015] Embodiment: an LED fluorescent tube, comprising a casing, several LEDs 1 and a circuit board for electrically connecting the LEDs, the casing is composed of a heat dissipation installation base 31 and a light transmission cover, and the circuit board is integrally formed on the heat dissipation The installation base, the LED1 is soldered to the heat dissipation installation base and electrically connected to the circuit board, and the heat dissipation installation base is buckled with the light transmission cover. That is, the heat dissipation installation base 31 of the housing of the LED fluorescent tube in this embodiment is an integrated heat dissipation installation base integrating heat dissipation and circuit boards, which can improve heat dissipation efficiency, allow the heat generated by the LED to be quickly conducted, and reduce light emission. The attenuation and aging of the chip due to excessive temperature. In this way, it can be avoided that the traditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com