Preparation method of thermal conductive film based on graphene polyimide composite sponge precursor

A polyimide precursor, ene polyimide technology, is applied in the field of preparation of a thermal conductive film based on a graphene polyimide composite sponge precursor, and achieves the effects of reducing grain boundary scattering, improving electrical conductivity, and reducing interface thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

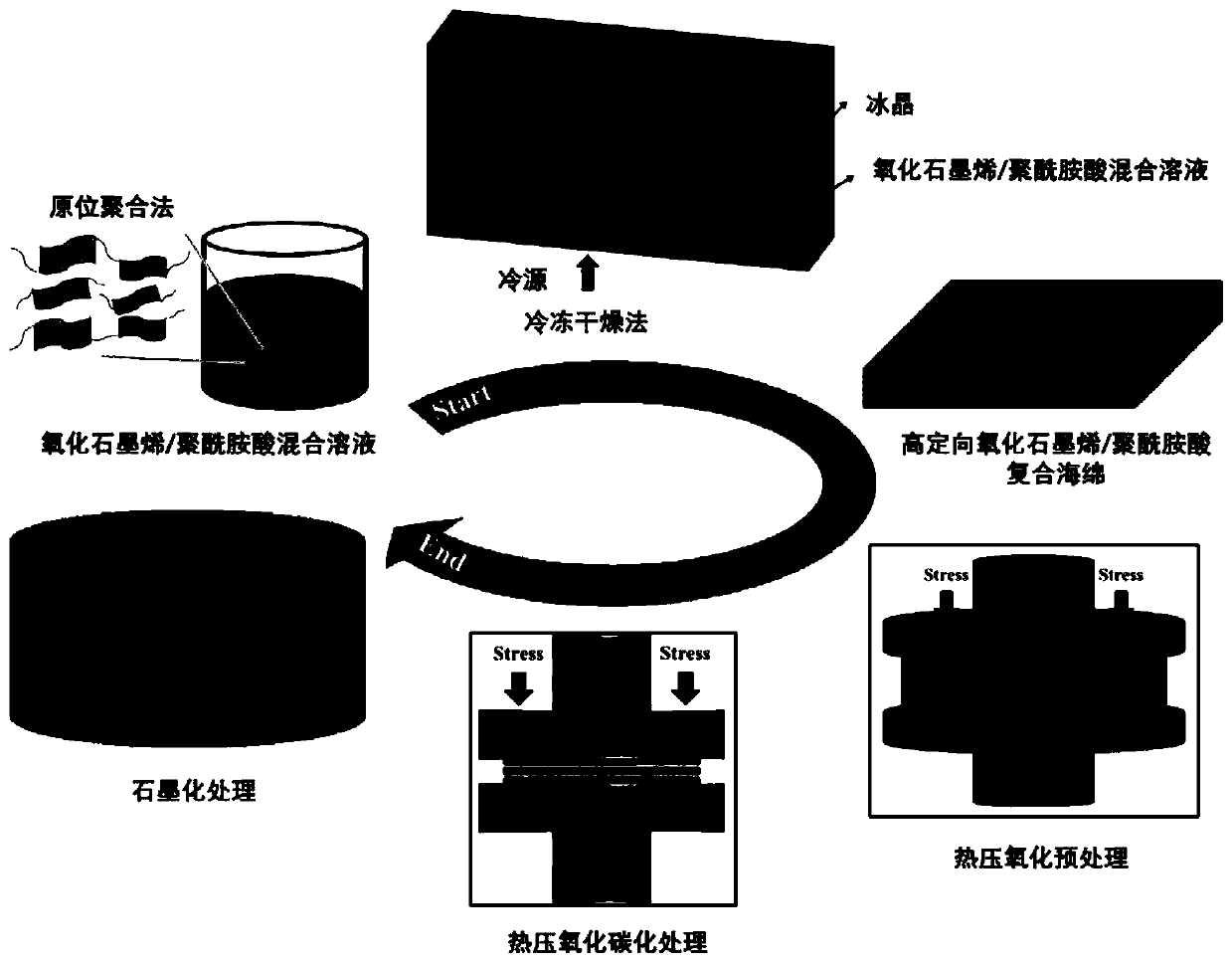

[0059] A thermally conductive film based on graphene / polyimide composite sponge precursor is prepared by the following steps, and the schematic diagram of the preparation process is as follows: figure 1 Shown:

[0060] 1. Preparation of graphene oxide aqueous solution: measure 20mL graphene oxide slurry, add deionized water; under the condition of stirring speed of 700r / min, after stirring for 60min; and at a frequency of 100KHz, perform ultrasonic treatment for 30min to obtain Graphene oxide aqueous solution.

[0061] Wherein, the concentration of the graphene oxide slurry is 20 mg / mL; the concentration of graphene oxide in the graphene oxide aqueous solution is 5 mg / mL.

[0062] 2. Preparation of polyimide precursor solution:

[0063] Using an electromagnetic stirrer, 1.98g of monomeric diamine diaminodiphenyl ether (ODA) powder was uniformly dispersed in 83mL of polar solvent dimethylacetamide (DMAc) solution; 2.18g of dianhydride was continuously added to the mixed solut...

Embodiment 2

[0083]A thermally conductive film based on graphene / polyimide composite sponge precursor is prepared by the following steps:

[0084] 1. Preparation of graphene oxide aqueous solution:

[0085] Measure 20 mL of graphene oxide slurry, add deionized water; stir for 60 min at a stirring speed of 700 r / min; and perform ultrasonic treatment for 30 min at a frequency of 100 KHz to obtain a graphene oxide aqueous solution.

[0086] Wherein, the concentration of the graphene oxide slurry is 20 mg / mL; the concentration of graphene oxide in the graphene oxide aqueous solution is 5 mg / mL.

[0087] 2. Preparation of polyimide precursor solution:

[0088] Using an electromagnetic stirrer, 1.98g of monomeric diamine diaminodiphenyl ether (ODA) powder was uniformly dispersed in 83mL of polar solvent dimethylacetamide (DMAc) solution; 2.18g of dianhydride was continuously added to the mixed solution in small amounts Pyromellitic anhydride (PMDA) powder, stirred for 5h to make it fully react...

Embodiment 3

[0106] A thermally conductive film based on graphene / polyimide composite sponge precursor is prepared by the following steps:

[0107] 1. Preparation of graphene oxide aqueous solution:

[0108] Measure 20 mL of graphene oxide slurry, add deionized water; stir for 120 min at a stirring speed of 100 r / min; and perform ultrasonic treatment for 60 min at a frequency of 10 KHz to obtain a graphene oxide aqueous solution.

[0109] Wherein, the concentration of the graphene oxide slurry is 20 mg / mL; the concentration of graphene oxide in the graphene oxide aqueous solution is 4 mg / mL.

[0110] 2. Preparation of polyimide precursor solution:

[0111] Using an electromagnetic stirrer, 1.98g of monomeric diamine diaminodiphenyl ether (ODA) powder was uniformly dispersed in 83mL of polar solvent dimethylacetamide (DMAc) solution; 2.18g of dianhydride was continuously added to the mixed solution in small amounts Pyromellitic anhydride (PMDA) powder, after stirring 5h to make it fully r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com