High-heat-conduction diamond/copper composite material and manufacturing method of high-heat-conduction diamond/copper composite material

A composite material and diamond technology, which is applied in the field of high thermal conductivity diamond/copper composite material and its preparation, can solve the problems of high brittleness, low thermal expansion coefficient and high cost, and achieves reduced interface thermal resistance, good thermal conductivity, and improved interface bonding state. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

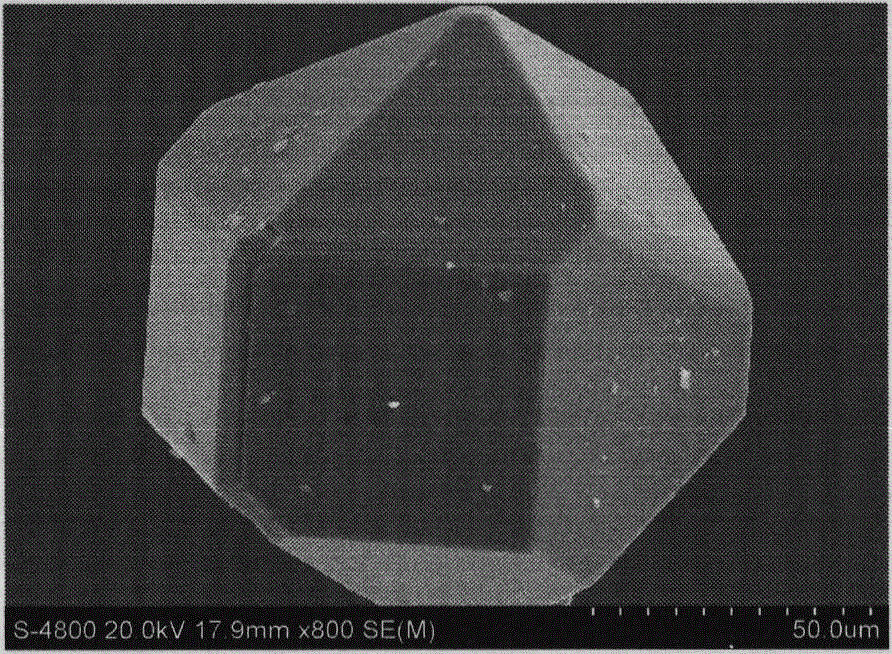

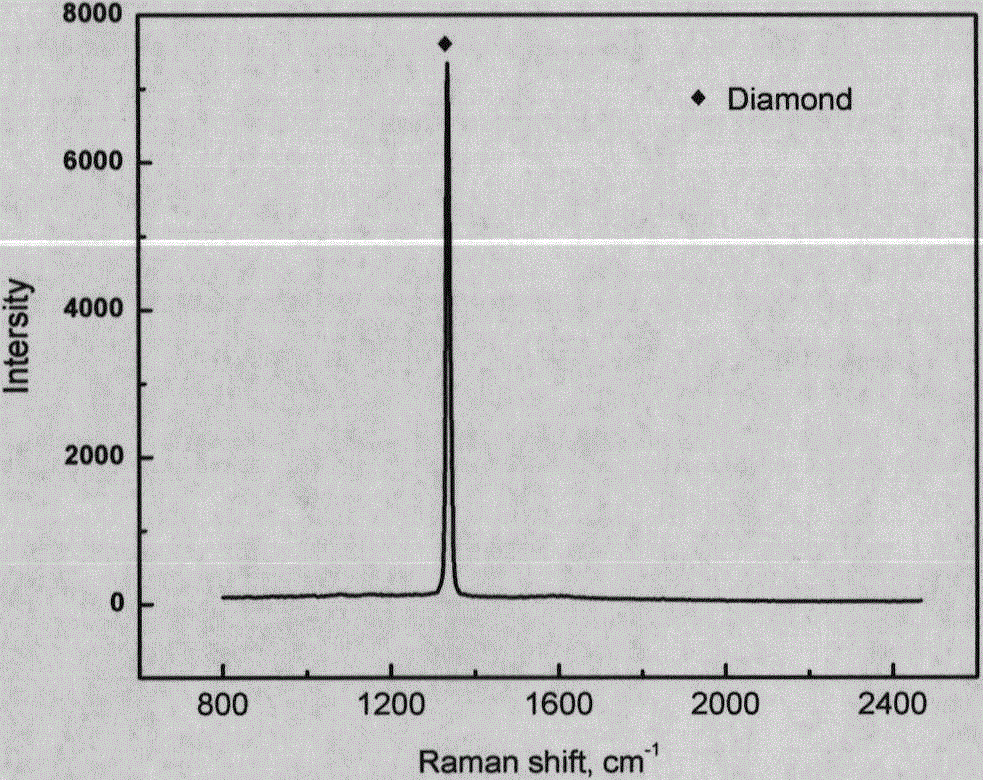

[0020] Put titanium-coated diamond particles with an average particle size of 130 μm into a small metal cup, and cover the diamond particles with a pure copper sheet. Then put the large metal cup on the small cup for assembly. The assembled cup was placed in a vacuum furnace at 550 °C for 2 h under vacuum, and then the cup was assembled in a pyrophyllite block for ultra-high pressure sintering.

[0021] The ultra-high pressure sintering process adopts the mode of first pressurizing and then heating up. The pressure is raised to 5GPa and then the temperature is raised. The sintering temperature is 1200°C for 5 minutes, and then the pressure is released after cooling down. The synthesized samples were machined to 12.7 x 3.5 mm. The resulting composite has a density of 3.99 g / cm 3 , the relative density is 99.46%, and the thermal conductivity is 647W / (m·K).

Embodiment 2

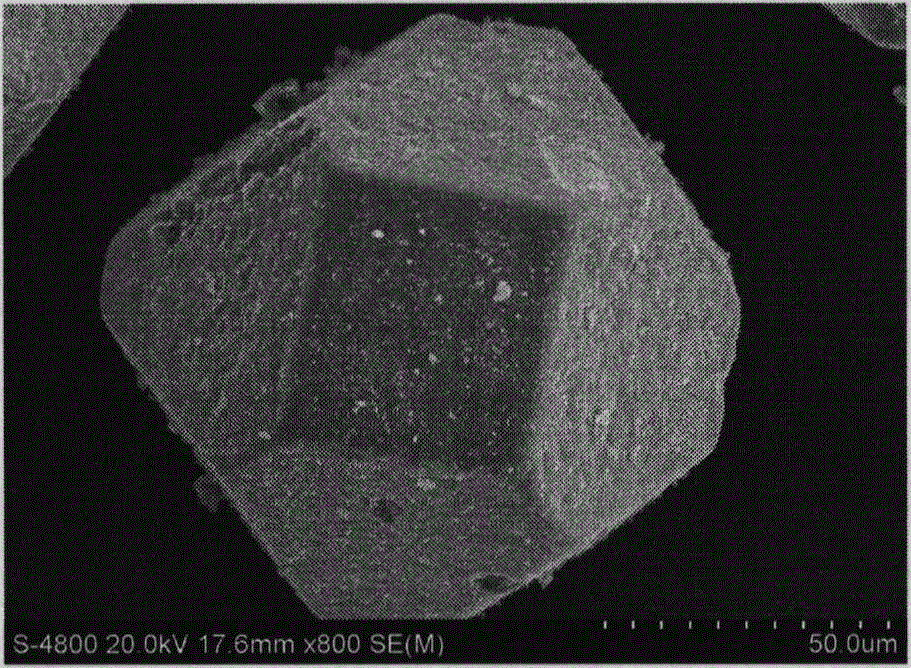

[0023] Put titanium-coated diamond particles with an average particle size of 160 μm into a small metal cup, and cover the diamond particles with a pure copper sheet. Then put the large metal cup on the small cup for assembly. Put the assembled cup into a vacuum furnace for 2 hours at 550°C for vacuum treatment, then assemble the cup into a pyrophyllite block for ultra-high pressure sintering. The sintering process is as follows: sintering temperature is 1200°C, pressure is 3GPa, holding time for 5min. The resulting composite had a density of 3.64 g / cm 3 , the relative density is 99.71%, and the thermal conductivity is 685W / (m·K).

Embodiment 3

[0025] Put titanium-coated diamond particles with an average particle size of 200 μm into a small metal cup, and cover the diamond particles with a pure copper sheet. Then put the large metal cup on the small cup for assembly. Put the assembled cup into a vacuum furnace for 2 hours at 550°C for vacuum treatment, then assemble the cup into a pyrophyllite block for ultra-high pressure sintering, the sintering process is: sintering temperature 1000°C, pressure 5GPa, holding time for 5min. The resulting composite has a density of 3.89 g / cm 3 , the relative density is 99.64%, and the thermal conductivity is 670W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com