TiC crystal whisker-reinforced metal ceramic and preparation method thereof

A cermet and whisker technology, which is applied in the field of cermet and its preparation, can solve the problems of poor wettability of SiC whiskers and inconspicuous effect of toughness, etc., achieve good stability, not easy to grow and coarsen, and improve strength The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

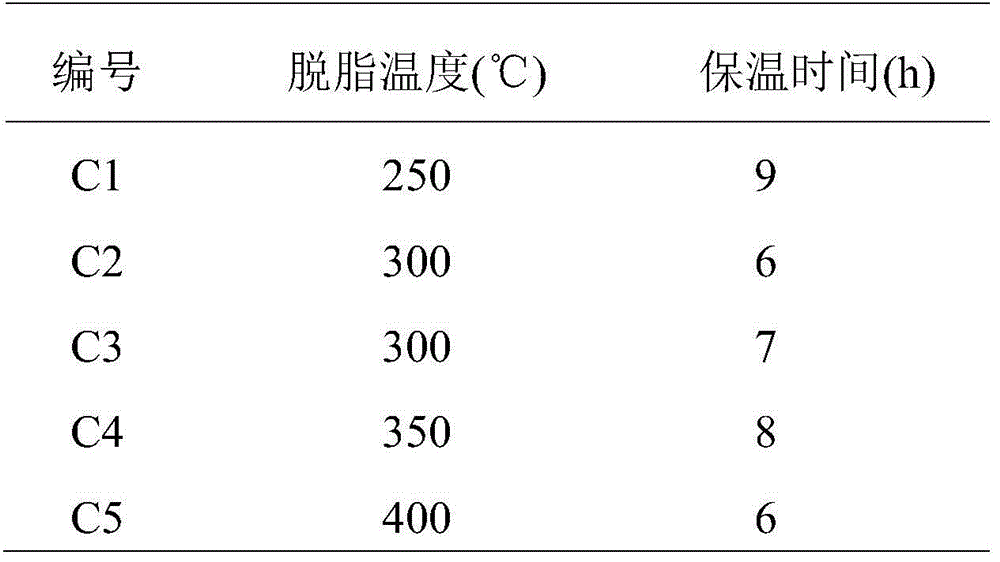

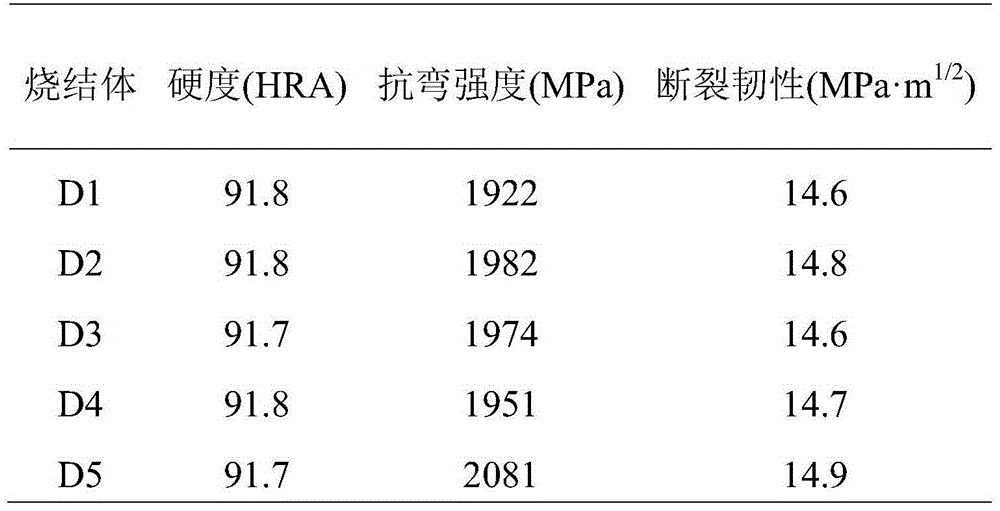

[0022] Embodiment 1: including raw material mixing step, TiC whisker dispersion step, drying and sieving step, molding step, degreasing step and vacuum sintering step:

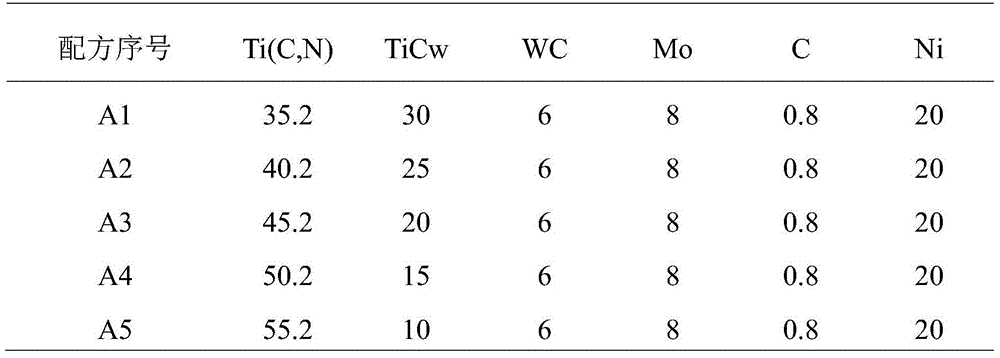

[0023] (1). Raw material mixing step: mix Ti(C,N) powder, TiC whisker, WC powder, Mo powder, C powder and Ni powder respectively according to the mass percentages shown in the formula numbers A1-A5 in Table 1; Mix the Ti(C,N) powder, WC powder, Mo powder, C powder and Ni powder in the formula numbers A1 to A5, and use a ball mill to wet grind, the mass ratio of ball to material is 5:1, the rotation speed is 120rpm, and the time is 24h to obtain the mixed Slurry B1-B5, wherein the particle size of Ti(C,N) powder is less than or equal to 200nm, the diameter of TiC whisker is 0.4-0.8μm, and the length is 10-60μm;

[0024] Table 1 TiCw reinforced cermet ingredient list

[0025]

[0026] (2). TiC whisker dispersing step: Put the TiC whiskers in the formula numbers A1 to A5 into the polar solvent ethanol, and ma...

Embodiment 2

[0035] Embodiment 2: including raw material mixing step, TiC whisker dispersion step, drying and sieving step, molding step, degreasing step and vacuum sintering step:

[0036] (1). Raw material mixing step: mix Ti(C,N) powder, TiC whisker, WC powder, Mo powder, C powder and Ni powder according to the mass percentages shown in the formula numbers E1-E8 in Table 4; The Ti(C,N) powder, WC powder, Mo powder, C powder and Ni powder in the serial numbers E1-E8 were mixed, and wet-milled by a ball mill with a ball-to-material ratio of 7:1 (mass ratio), a rotational speed of 220rpm, and a time of 36h to obtain Mixed slurry F1-F8, wherein the particle size of Ti(C,N) powder is less than or equal to 200nm, the diameter of TiC whisker is 0.4-0.8μm, and the length is 10-60μm;

[0037] Table 4 TiC whisker reinforced cermet ingredient list

[0038]

[0039] (2). TiC whisker dispersing step: Put the TiC whiskers in the formula numbers E1 to E8 into the polar solvent ethanol respectively...

Embodiment 3

[0049] Embodiment 3: including raw material mixing step, TiC whisker dispersion step, drying and sieving step, molding step, degreasing step and vacuum sintering step:

[0050] (1). Raw material mixing step: batching according to mass percentage: Ti(C,N) powder 35%, TiC whisker 15%, WC powder 10%, Mo powder 12%, C powder 1.0% and Ni powder 27%; The Ti(C,N) powder, WC powder, Mo powder, C powder and Ni powder were mixed, wet milled with a ball mill, the mass ratio of the ball to material was 6:1, the speed of the ball mill was 180rpm, and the ball milling time was 36h to obtain a mixed slurry. Among them, the particle size of Ti(C,N) powder is less than or equal to 200nm, the diameter of TiC whisker is 0.4-0.8μm, and the length is 10-60μm;

[0051] (2). Step of dispersing TiC whiskers: put TiC whiskers with a mass fraction of 15% into a polar solvent ethylene glycol, and make a suspension solution by ultrasonic vibration to ensure stable dispersion of TiC whiskers. Then the Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com