Preparation method of biodegradable magnesium alloy/calcium phosphate coating composite material

A technology of calcium phosphorus coating and composite materials, which is applied in the field of preparation of biomedical degradable materials, can solve the problems of material failure, too fast degradation, and no systematic evaluation standards and systems for clinical application performance, so as to improve corrosion resistance , reduce the degradation rate, promote the effect of research and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Pretreatment of the substrate: the magnesium alloy is cut into moderately sized samples with a wire cutting machine, and polished with 2000# alumina water-resistant sandpaper to remove the oxide layer on the surface of the sample. Ultrasonic cleaning with water and ethanol for 10 min, and drying at room temperature for later use.

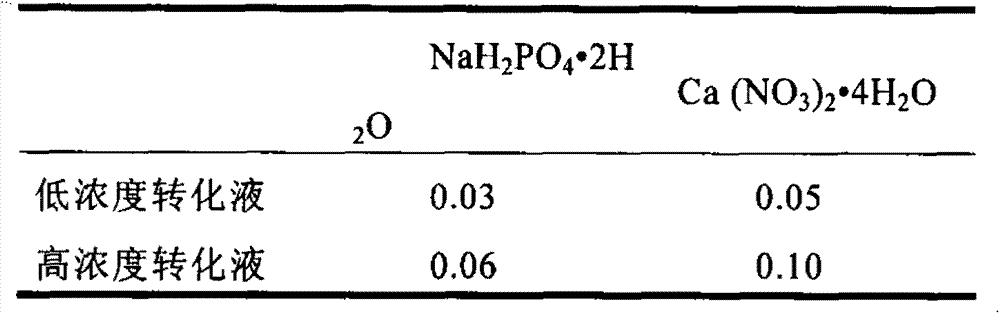

[0021] (2) Configuration of conversion solution: The conversion solution used was prepared from sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate, and a low-concentration conversion solution (as shown in Table 1) was prepared, wherein the solvent was deionized water.

[0022] (3) Preparation of biomimetic calcium-phosphorus coating: Put the processed sample and the transformation solution into the inner tank of the hydrothermal kettle. Cover, put the water heating kettle into the furnace to heat. Heat treatment at 100°C for 2.5 hours to prepare calcium phosphorus coating;

[0023] (4) Performance testing: corrosion ...

Embodiment 2

[0025] (1) Pretreatment of the substrate: the magnesium alloy is cut into moderately sized samples with a wire cutting machine, and polished with 2000# alumina water-resistant sandpaper to remove the oxide layer on the surface of the sample. Ultrasonic cleaning with water and ethanol for 20 min, and drying at room temperature for later use.

[0026] (2) Configuration of conversion solution: The conversion solution used was prepared from sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate, and a low-concentration conversion solution (as shown in Table 1) was prepared, wherein the solvent was deionized water.

[0027] (3) Preparation of biomimetic calcium-phosphorus coating: Put the processed sample and 80ml of conversion liquid into the inner tank of the hydrothermal kettle, the volume of the conversion solution accounts for 1 / 2 of the volume of the inner tank of the hydrothermal kettle, and tighten the water heating kettle Metal lid, put the hydrothermal ket...

Embodiment 3

[0030] (1) Pretreatment of the substrate: the magnesium alloy is cut into moderately sized samples with a wire cutting machine, and polished with 2000# alumina water-resistant sandpaper to remove the oxide layer on the surface of the sample. Water and ethanol ultrasonic cleaning for 30min, and dry at room temperature, set aside.

[0031] (2) Configuration of conversion solution: The conversion solution used was prepared from sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate, and a low-concentration conversion solution (as shown in Table 1) was prepared, wherein the solvent was deionized water.

[0032] (3) Preparation of biomimetic calcium-phosphorus coating: Put the processed sample and the transformation solution into the inner tank of the hydrothermal kettle. Cover, put the water heating kettle into the furnace to heat. Heat treatment at 140°C for 1.5h to prepare calcium phosphorus coating;

[0033] (4) Performance testing: corrosion performance chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com