Device for repairing fractured bones and method for manufacturing device

A technology of bone and bone repair medium, applied in bone implants, medical science, prosthesis, etc., can solve the problem of poor biocompatibility and biomechanical properties, poor biodegradability and strength balance of fixation devices, materials - Problems such as poor bone tissue interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

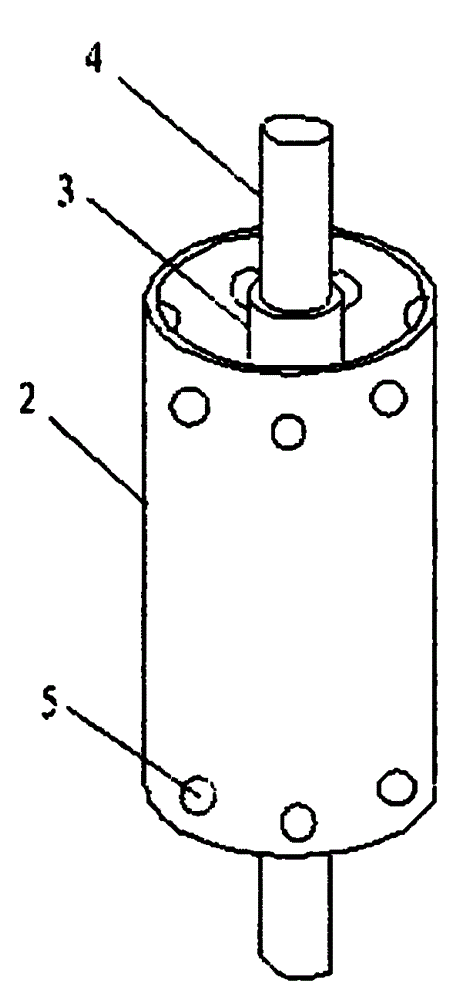

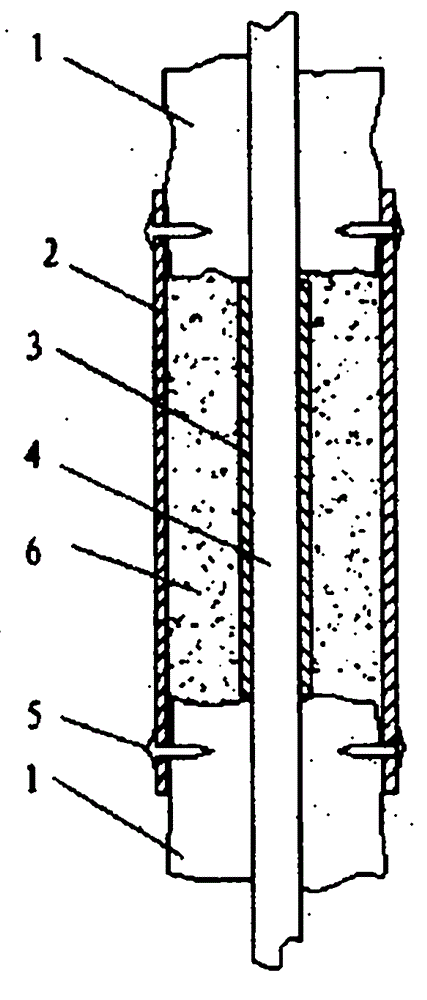

[0040] Such as figure 1 As shown, the device for repairing fractured bones consists of an outer sleeve 2 , an inner sleeve 3 and a connecting rod 4 . The two ends of the outer sleeve 2 are sleeved on the two ends of the tubular bone defect requiring bone grafting, and fixed by screws 5 . The inner sleeve 3 is located in the outer sleeve 2, the connecting rod 4 is inserted into the inner sleeve 3, the diameter of the connecting rod 4 matches the inner diameter of the inner sleeve 3, and the two ends of the connecting rod 4 are inserted into the marrow of the tubular bone 1 cavity. The connecting rod 4 is a rod-shaped or column-shaped structure, and an intramedullary nail can generally be used. The walls of the inner sleeve and the outer sleeve have a mesh structure, and the inner sleeve and the outer sleeve are made of degradable magnesium alloy. The degradable magnesium alloy material not only has bone grafting and enhanced fixation stability, but also It has the effect of ...

Embodiment 2

[0042] Such as figure 1 As shown, the method of using the device in Example 1 is as follows: first, fill the space between the outer sleeve 2 and the inner sleeve 3 with the patient's own high-quality cancellous bone; then pull the defective tubular bone 1 to both ends, Place the outer sleeve 2 and the inner sleeve 3 at the defect position of the tubular bone 1, and the two ends of the inner sleeve 3 are opposite to the center of the two ends of the tubular bone 1; then align the defective tubular bone 1 to the middle, so that the outer sleeve The two ends of 2 are set on the tubular bone 1 at both ends; the connecting rod 4 is driven from one end of the tubular bone 1 along the medullary cavity, and the intramedullary nail is generally used, and the intramedullary nail passes through the inner sleeve 3 and enters the tubular bone The medullary cavity at the lower part of 1 firmly connects the two sections of tubular bone 1; finally, the outer sleeve 2 is firmly connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com