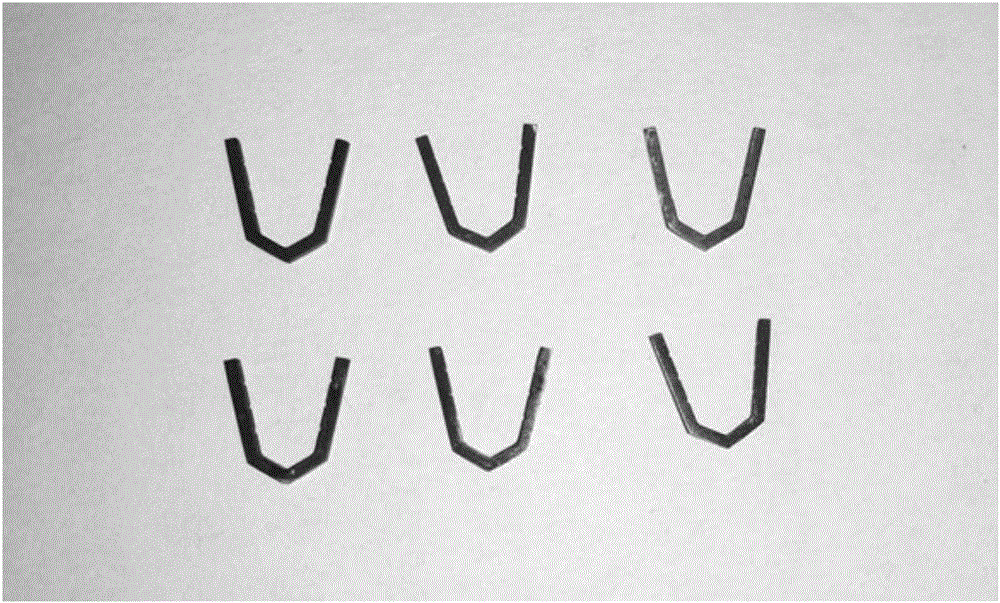

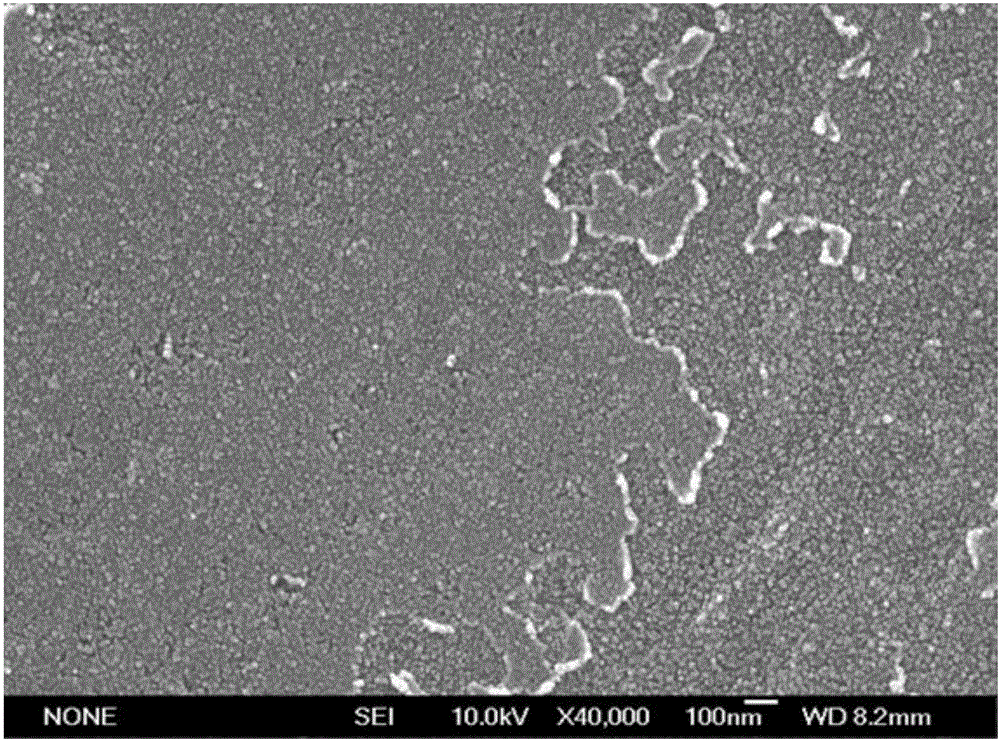

Method for preparing hemostatic clips through surface-passivated degradable magnesium alloy

A magnesium alloy, hemostatic clip technology, applied in wound clips, metal material coating processes, etc., to achieve the effect of ensuring effectiveness, improving blood biocompatibility, and reducing degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a hemostatic clip using a degradable magnesium alloy with a surface passivation. The degradable magnesium alloy material is composed of Mg, Zn, Zr, and Sr, and the mass percentage of each component is: Zn is 3%, Zr is 0.8%, Sr is 0.3%, Mg is the balance, the preparation steps are as follows:

[0020] 1) Add 99.99wt% Mg, analytically pure Zn, Mg-Zr master alloy and Mg-Sr master alloy to the graphite crucible, wherein the mass percentage of Zr in the Mg-Zr master alloy is 30%, and Mg-Sr The mass percentage of Sr in the composition of the master alloy is 30%, evacuated to 1×10 -2 Pa, pass argon protection, heat to 780°C and keep it warm for 20 minutes, then fully stir at 8r / s for 10 minutes and then start to cool down. After the temperature drops to 650°C, pour into the crystallizer to obtain a 60mm diameter ingot;

[0021] 2) Put the above round ingot in an air furnace, heat it at 350℃ for 6h for homogenization annealing, then heat it to 500℃ for 1h for ...

Embodiment 2

[0028] A method for preparing a hemostatic clip using a degradable magnesium alloy with a passivation surface. The degradable magnesium alloy material is composed of Mg, Zn, Zr, Ca and Ag, and the mass percentage of each component is: Zn is 3%, Zr It is 0.7%, Ca is 0.3%, Ag is 0.3%, and Mg is the balance. The preparation steps are as follows:

[0029] 1) Add 99.99wt% Mg, analytically pure Zn, Mg-Zr master alloy, Mg-Ca master alloy and Mg-Ag master alloy to the graphite crucible, where the mass percentage of Zr in the Mg-Zr master alloy is 30%, the mass percentage of Ca in the Mg-Ca master alloy composition is 30%, the mass percentage of Ag in the Mg-Ag master alloy is 30%, and vacuum to 1×10 -2 Pa, pass argon protection, heat to 780°C and keep it warm for 20 minutes, then fully stir at 8r / s for 10 minutes and then start to cool down. After the temperature drops to 650°C, pour into the crystallizer to obtain a 60mm diameter ingot;

[0030] 2) Put the above ingot in an air furnace, k...

Embodiment 3

[0036] A method for preparing a hemostatic clip using a degradable magnesium alloy with a surface passivation. The degradable magnesium alloy material is composed of Mg, Zn, Zr, and Ca, and the mass percentage of each component is: Zn is 3%, Zr is 0.6 %, Ca is 0.3%, Mg is the balance, the preparation steps are as follows:

[0037] 1) Add 99.99wt% Mg, analytically pure Zn, Mg-Zr master alloy, and Mg-Ca master alloy to the graphite crucible, wherein the mass percentage of Zr in the Mg-Zr master alloy is 30%, and Mg-Ca The mass percentage of Ca in the composition of the master alloy is 30%, evacuated to 1×10 -2 Pa, pass argon protection, heat to 780°C and keep it warm for 20 minutes, then fully stir at 8r / s for 10 minutes and then start to cool down. After the temperature drops to 650°C, pour into the crystallizer to obtain a 60mm diameter ingot;

[0038] 2) Put the above-mentioned round ingot in an air furnace, keep it at 300℃ for 36h for homogenization annealing, then heat up to 450...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com