Polyphenol substance hydrogen bond enhanced hydrogel

A technology of hydrogel and polyphenols, applied in aerosol delivery, bandage, emulsion delivery, etc., can solve problems such as poor mechanical properties, achieve enhanced mechanical properties, broad application prospects, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

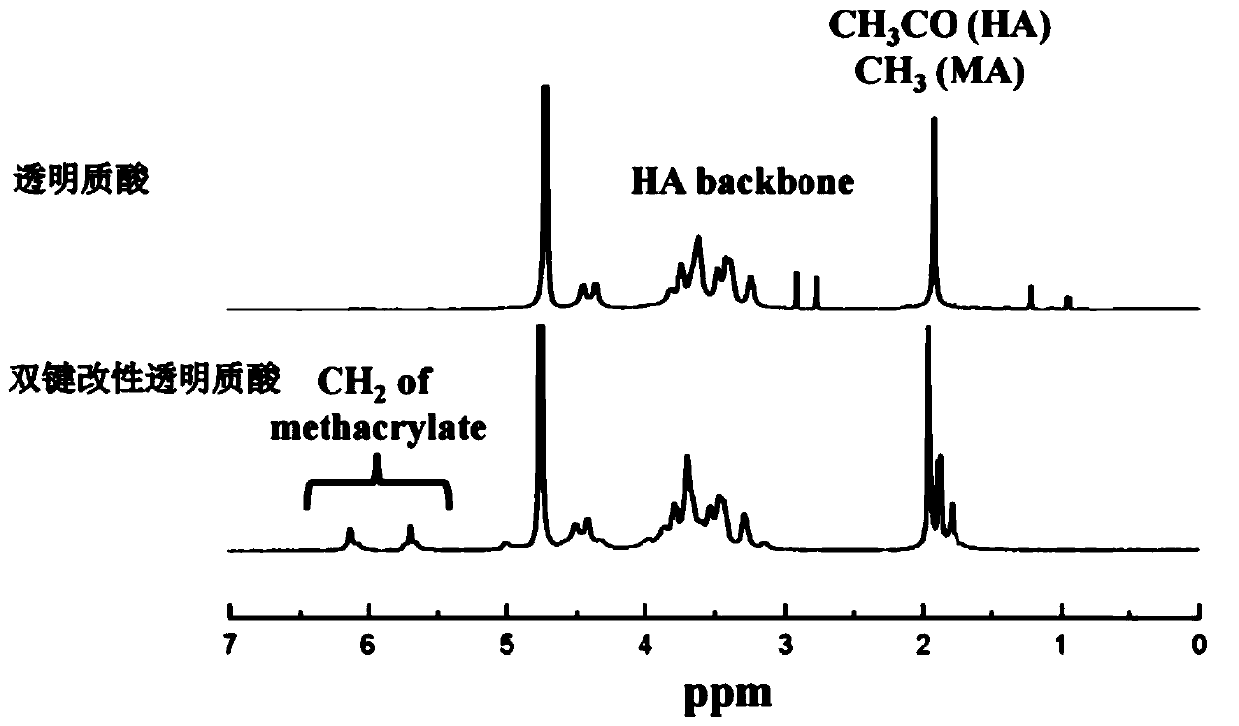

[0035] 1. Preparation of double bond modified hyaluronic acid

[0036] 1 g of hyaluronic acid was stirred and dissolved in 100 mL of mixed solvent (DMF:water=1:2, v:v). After fully dissolving, cool down to 4°C in an ice-water bath, and adjust the pH to 8-9 with 5M (mol / L) sodium hydroxide solution. Slowly add 3.7 mL of methacrylic anhydride dropwise, and stir overnight at 4° C. to maintain a stable pH value between 8 and 9. The reacted solution was poured into 1L of absolute ethanol, and stood at 4° C. overnight to completely precipitate MA-HA (methacrylic anhydride-hyaluronic acid). Centrifuge, redissolve the precipitated product in ultrapure water, dialyze through a dialysis bag with a molecular weight of 14,000, change the water every 4 hours, freeze-dry after 5 days of dialysis, and obtain methacrylic anhydride-modified hyaluronic acid, that is, double-bond modified hyaluronic acid acid.

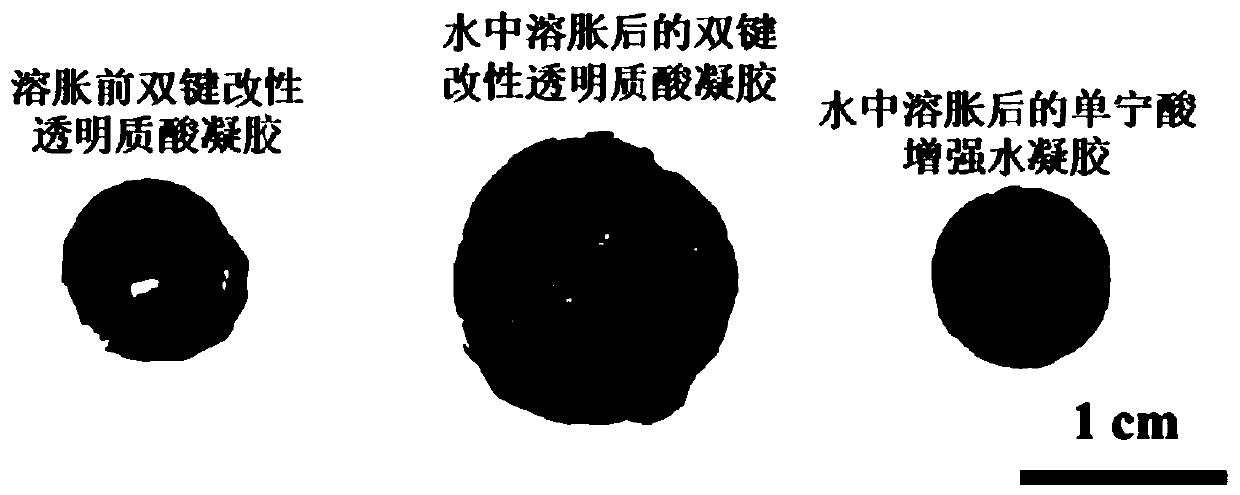

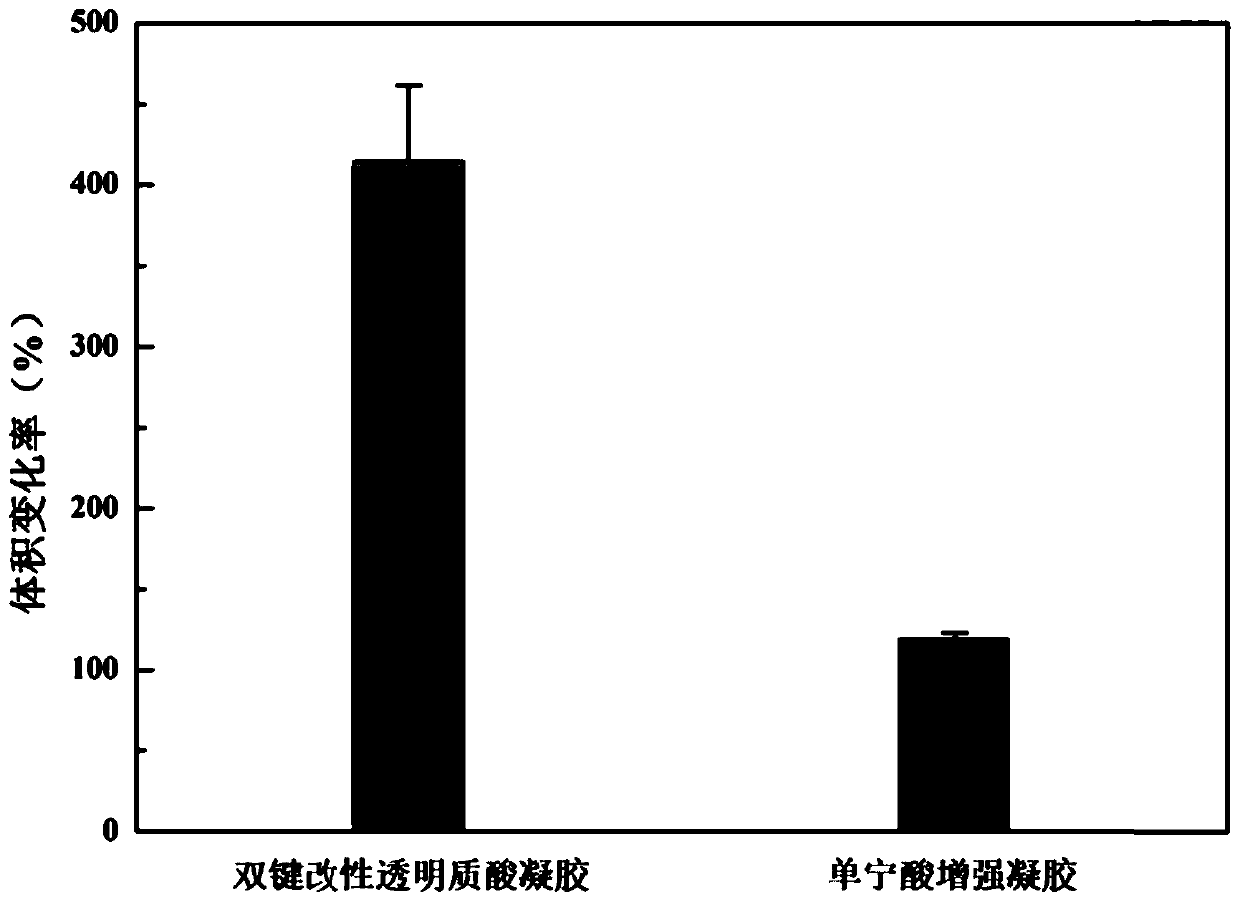

[0037] 2. Preparation of tannin-enhanced hyaluronic acid hydrogel

[0038] 2% (w...

Embodiment 2

[0042]1. Preparation of sodium alginate hydrogel

[0043] Prepare 5% (w / v) sodium alginate aqueous solution. Prepare a calcium chloride solution with a certain concentration (such as 10mmol / L), and add it dropwise to the sodium alginate aqueous solution until the gel is formed. Stand at room temperature for 2 hours for later use.

[0044] 2. Preparation method of tannic acid enhanced sodium alginate gel

[0045] Prepare a Tris buffer solution with a pH=8.5 and a concentration of 0.1M. A 10 mg / mL tannic acid / Tris solution was prepared, the prepared gel was soaked in it, and shaken at room temperature for 4 days in the dark. After taking out, rinse with phosphate buffered saline solution (PBS) of pH=7.4 for 3 times to obtain tannic acid enhanced sodium alginate gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com