Heavy-duty metal processing cutting lubricant and preparation method thereof

A metal processing and lubricant technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of hidden dangers in production enterprises, short tool life cycle, polluted working environment, etc., and achieve the advantages of simple operation, low cost and improved surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of heavy-duty metal processing cutting lubricant, it is made up of the raw material of following percentage by weight: 3% mineral oil, 2% component A, 1% component B, 1% component C, 1% component Part D, 15% component E, 2% antirust agent, the sum of the weight percentages of the mineral oil, component A, component B, component C, component D, component E and antirust agent is 100 %;

[0028] Among them: mineral oil is one or more of transformer oil, rubber oil, machine oil and white oil;

[0029] Component A is one or more of oleic acid, linoleic acid, palmitic acid, dimerized cottonseed oleic acid, lauryl alcohol, ethanol oleate and rapeseed oil;

[0030] Component B is one or more of sodium hydroxide, potassium hydroxide, monoethanolamine and diethanolamine;

[0031] Component C is one or more of abietic acid amide, sorbitol polyoxyethylene ether, castor oil and ethylene oxide condensate, betaine, alkyl polyglycoside and sulfonated castor oil; ...

Embodiment 2

[0037] Embodiment 2: other conditions of the present invention's heavy-duty metalworking cutting lubricant are all the same, and the difference is the percentage by weight of each component, and this embodiment is made up of the raw material of following percentage by weight: 20% mineral oil, 10% component Component A, 10% component B, 8.5% component C, 5.5% component D, 55% component E, 12% rust inhibitor, the mineral oil, component A, component B, component C, The sum of the percentage by weight of component D, component E and antirust agent is 100%;

Embodiment 3

[0038]Embodiment 3: Other conditions of the heavy-duty metalworking cutting lubricant of the present invention are all the same, the difference is the weight percentage of each component, and the present embodiment is made up of the raw material of following weight percentage: 12% mineral oil, 8% component Component A, 7% component B, 6.5% component C, 5% component D, 50% component E, 6% rust inhibitor, the mineral oil, component A, component B, component C, The sum of the weight percentages of component D, component E and antirust agent is 100%.

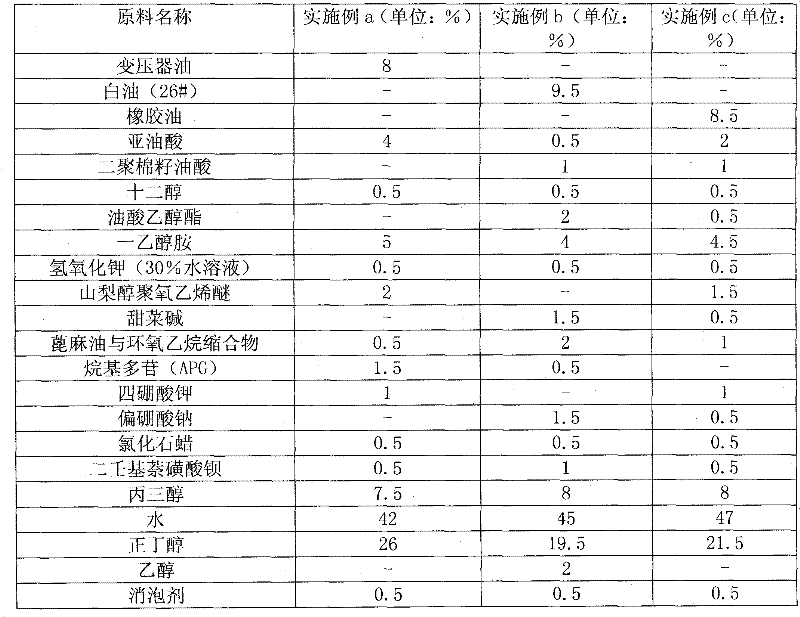

[0039] Table 1 is the formula composition of 3 specific embodiments of the heavy-duty metalworking cutting lubricant of the present invention;

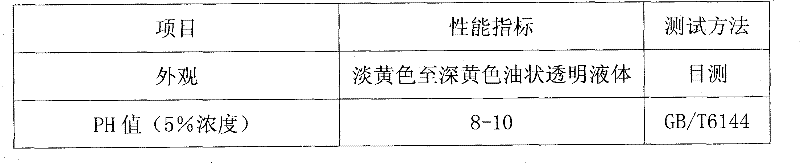

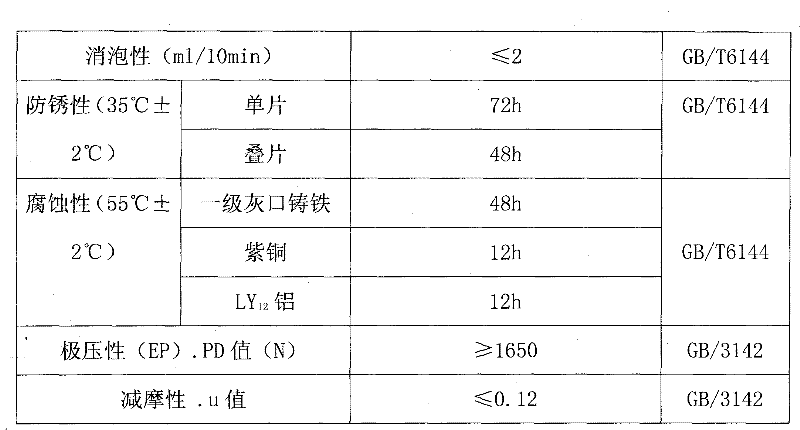

[0040] Table 2 shows various technical indicators of the heavy-duty metal processing cutting lubricant of the present invention.

[0041] Table one: the present invention provides the formula composition of 3 embodiment a, embodiment b and embodiment c in addition

[0042]

[0043] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com