Metal fiber wire and its producing process

A metal fiber wire and manufacturing process technology, applied in the field of metal processing, can solve the problems of many annealing times, low comprehensive performance and high linear speed, and achieve the effect of improving comprehensive performance and overcoming poor drawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

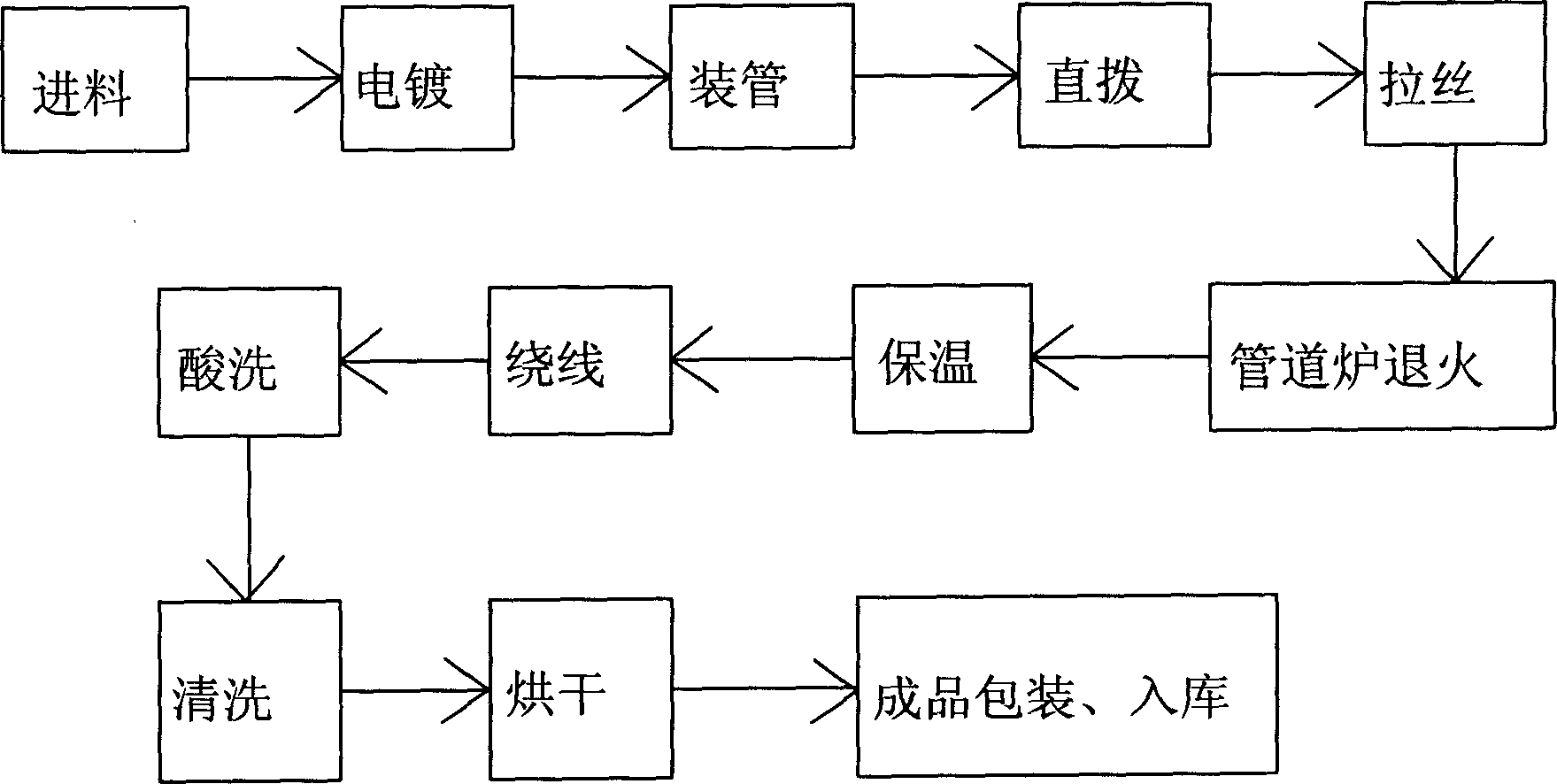

Method used

Image

Examples

Embodiment 1

[0014] A kind of metal fiber filament, its composition comprises following component (expressed in wt.%):

[0015] Carbon: 0.04%, Manganese: 0.25%, Silicon: 0.45%, Lanthanum or Cerium: 0.03%, Aluminum: 5.0%, Chromium: 17%, Copper: 0.06%, Sulfur: 0.03%, Phosphorus: 0.04%, Iron: 77.1 %.

Embodiment 2

[0017] A kind of metal fiber filament, its composition comprises following component (expressed in wt.%):

[0018] Carbon: 0.05%, Manganese: 0.3%, Silicon: 0.5%, Lanthanum or Cerium: 0.05%, Aluminum: 5.0%, Chromium: 19%, Copper: 0.08%, Sulfur: 0.03%, Phosphorus: 0.04%, Iron: 74.95 %.

Embodiment 3

[0020] A kind of metal fiber filament, its composition comprises following component (expressed in wt.%):

[0021] Carbon: 0.06%, Manganese: 0.36%, Silicon: 0.55%, Cerium or Lanthanum: 0.08%, Aluminum: 5.0%, Chromium: 21%, Copper: 1%, Sulfur: 0.04%, Phosphorus: 0.05%, Iron 67.12% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com