UiO-66-NH2 composite material as well as preparation method thereof and application of composite material in seawater desalination

A technology of uio-66-nh2 and composite materials, applied in seawater treatment, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as harsh conditions, achieve easy operation, excellent seawater desalination performance, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] In a preferred embodiment, the present invention also provides UiO-66-NH 2 A method for preparing a composite material, comprising the steps of:

[0073] i) Provide UiO-66-NH 2 Membrane reaction solution and porous alumina tubular support modified by APTES; and

[0074] ii) By solvothermal reaction, UiO-66-NH 2 The membrane is supported on the surface of the porous alumina tubular support modified by APTES to obtain UiO-66-NH 2 composite material.

[0075] In another preferred example, the temperature of the solvothermal reaction in step ii) is 100-150°C.

[0076] In another preferred embodiment, after step ii), a step is further included: washing the product with a solvent, and drying the product obtained in the previous step at 20-40°C.

[0077] In another preferred example, the drying time is 1-48 hours, preferably 15-30 hours.

[0078] In another preference, the UiO-66-NH 2 Membranes were prepared as follows:

[0079] a-1) providing a first mixed solution, s...

Embodiment 1

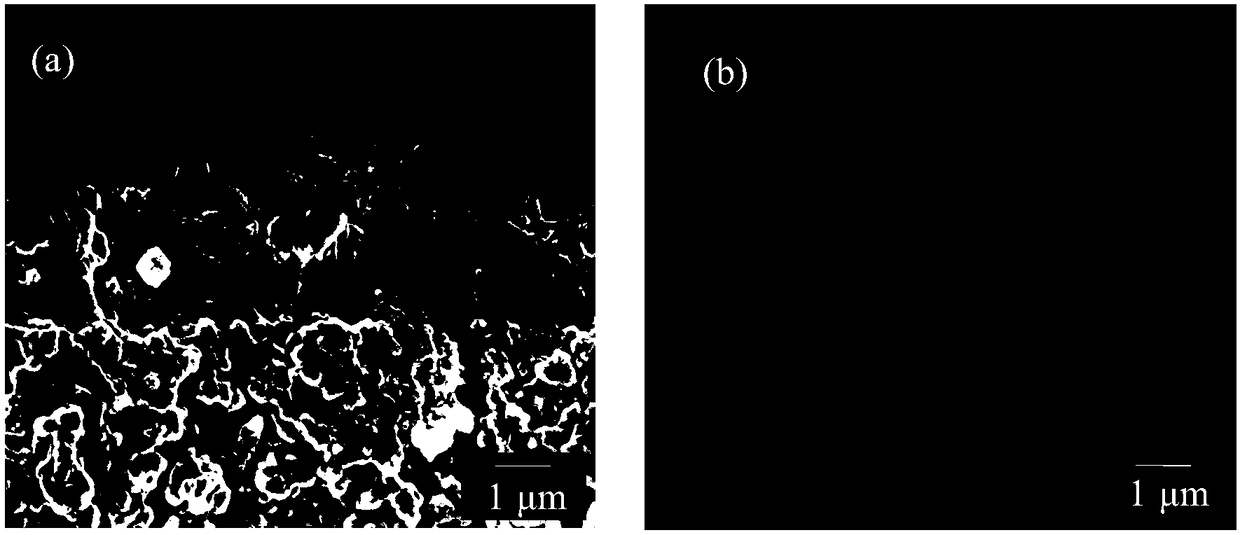

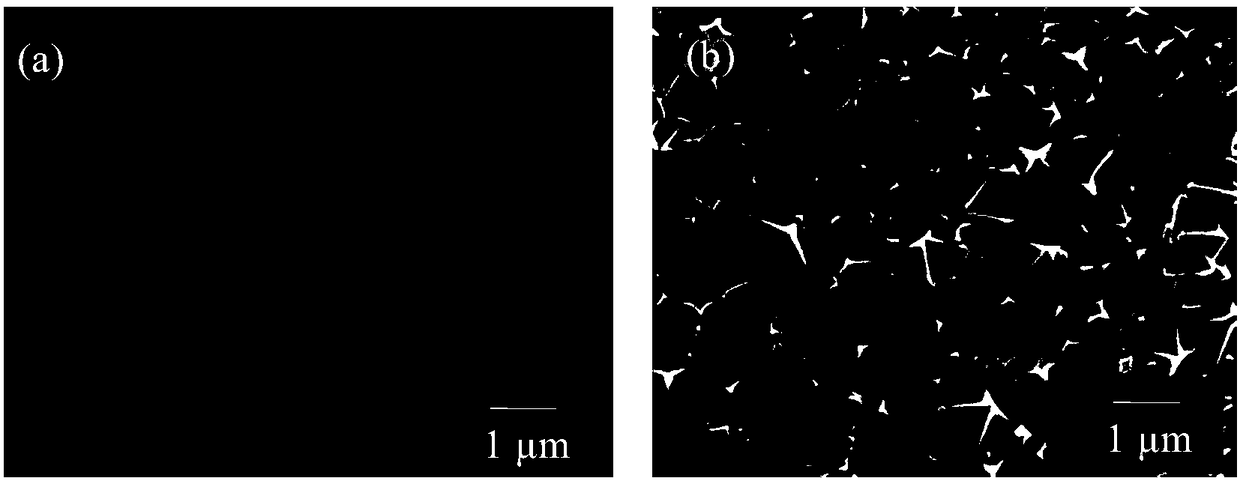

[0115] UiO-66-NH 2 composite material 1

[0116] Step 1. Functional modification of the carrier

[0117] Put the porous alumina ceramic tube collectively into the toluene solution of APTES with a concentration of 0.2mol / L, and react at 383K for 90min, thereby introducing -NH on the surface of the carrier 2 functional groups to facilitate the growth of MOF films.

[0118] Among them, the outer diameter of the ceramic tube is 12 mm, the inner diameter is 9 mm, the length is 75 mm, the pore diameter is 1.0 μm, and the porosity is 30%.

[0119] Step 2. Preparation of synthetic solution

[0120] Weigh 320mg of zirconium tetrachloride and 250mg of 2-aminoterephthalic acid, add 50ml of DMF (N,N'dimethylformamide), add 0.0247g of ultrapure water, and stir magnetically for 30min.

[0121] Step 3, UiO-66-NH 2 membrane growth

[0122] After the functionalized modified carrier was fixed, it was placed in a reaction kettle filled with synthesis solution, taken out after in-situ hydro...

Embodiment 2

[0132] Step 1. Functional modification of the carrier

[0133] Put the porous alumina ceramic tube collectively into the toluene solution of APTES with a concentration of 0.2mol / L, and react at 383K for 110min, thereby introducing -NH on the surface of the carrier 2 functional groups to facilitate the growth of MOF films.

[0134] Among them, the outer diameter of the ceramic tube is 12 mm, the inner diameter is 9 mm, the length is 65 mm, the pore diameter is 1.8 μm, and the porosity is 20%.

[0135] Step 2. Preparation of synthetic solution

[0136] Weigh 320mg of zirconium tetrachloride and 250mg of 2-aminoterephthalic acid, add 50ml of DMF (N,N'dimethylformamide), add 0.0247g of ultrapure water, and stir magnetically for 30min.

[0137] Step 3, UiO-66-NH 2 membrane growth

[0138] After the functionalized modified carrier was fixed, it was placed in a reaction kettle filled with synthesis solution, taken out after in situ hydrothermal synthesis at 383K for 40 hours, coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com