Method for separating 2,3-butanediol

A butanediol, fully mixed technology, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as affecting purification, increasing production costs, environmental pollution, etc. Reduce, increase concentration, realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

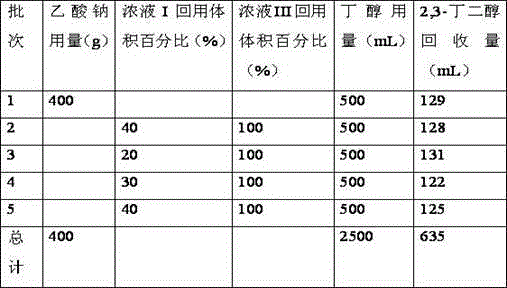

Examples

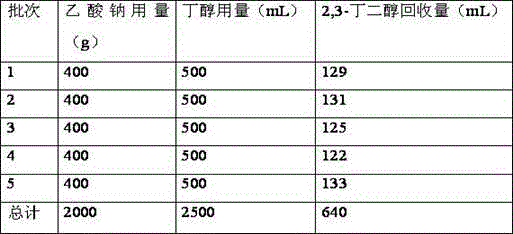

Embodiment 1

[0031] (1) Aqueous two-phase extraction: Take 2L of the fermentation broth, add 400g of sodium acetate, mix well, add 500mL of butanol, mix well and let stand.

[0032] (2) Electrodialysis desalination:

[0033] A. Take 600 mL of supernatant liquid obtained by two-phase extraction and perform electrodialysis. When the conductivity is less than 100 μS / cm, collect the supernatant liquid and concentrated liquid I to obtain 200 mL of concentrated liquid I.

[0034] B. Take 2300 mL of the lower phase clear liquid obtained by two-phase extraction and perform electrodialysis. When the conductivity is <300 μS / cm, collect the dope III to obtain 800 mL of dope III.

[0035] (3) Rectification: The clear liquid obtained in step (2) A was subjected to atmospheric distillation, and the butanol fraction was collected at 118°C, and the 2,3-butanediol fraction was collected at 180°C.

[0036] Results: 131mL of 2,3-butanediol was evaporated at about 180℃; the total recovery rate of 2,3-butaned...

Embodiment 2

[0038] (1) Aqueous two-phase extraction: Take 4L of the fermentation clear liquid, add 1200g of potassium succinate, mix well, add 1500mL of oleyl alcohol, mix well and let stand.

[0039](2) Electrodialysis desalination:

[0040] A. Take 1630 mL of supernatant liquid obtained by two-phase extraction for electrodialysis. When the conductivity is <100 μS / cm, collect the supernatant liquid and dope I.

[0041] B. Take 4350mL of the lower phase clear solution obtained by two-phase extraction for electrodialysis, and use the concentrated solution I as the electrodialysis circulating fluid. When the conductivity is <300μS / cm, collect 2400mL of the concentrated solution II.

[0042] (3) Rectification: The clear liquid obtained in step (2) A was subjected to atmospheric distillation, and the 2,3-butanediol fraction was collected at 180°C, and no salt components were separated out of the still residue.

[0043] Results: 240mL of 2,3-butanediol was evaporated at about 180℃; the total ...

Embodiment 3

[0045] (1) Aqueous two-phase extraction: Take 2L of the fermentation clear liquid, add 20mL of concentrated solution I and 800mL of concentrated solution III in step (2) in Example 1, and add 1000mL of butanol, mix well and let stand.

[0046] (2) Electrodialysis desalination:

[0047] A. Take 1300 mL of the supernatant liquid obtained by two-phase extraction for electrodialysis, and when the conductivity is <100 μS / cm, collect the supernatant liquid and concentrated liquid I.

[0048] B. Take 2300 mL of the lower phase clear liquid obtained by the two-phase extraction and perform electrodialysis. When the conductivity is <300 μS / cm, collect the concentrated liquid III.

[0049] (3) Rectification: The clear liquid obtained in step (2) A was subjected to atmospheric distillation, and the butanol fraction was collected at 118°C, and the 2,3-butanediol fraction was collected at 180°C.

[0050] Results: 128mL of 2,3-butanediol was evaporated at about 180℃; the total recovery rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com