Liquid circulation system and liquid cooling system therewith

a circulation system and liquid cooling technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of small impellers that cannot increase flow rates, lose the general versatility of pumps themselves, and reduce the flow rate of coolant. , to achieve the effect of reducing the loss of pressure drop in piping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

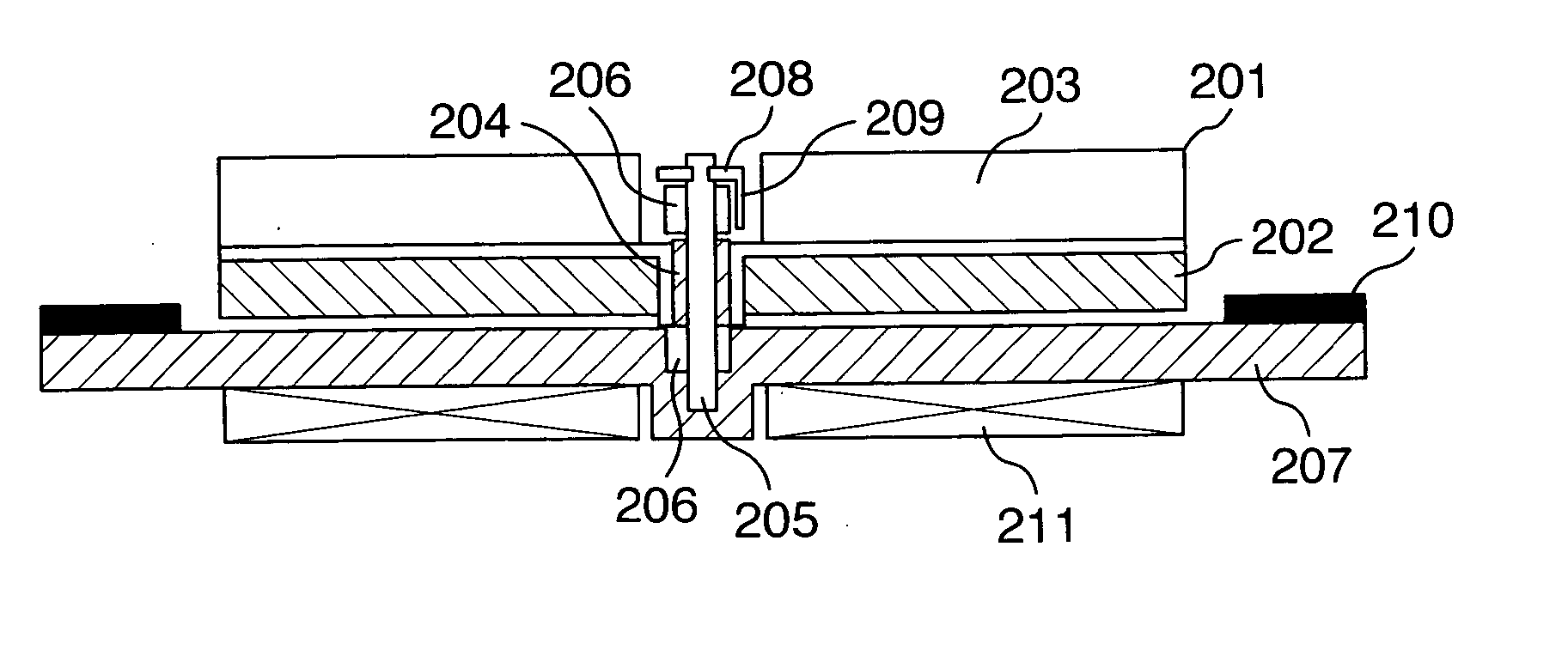

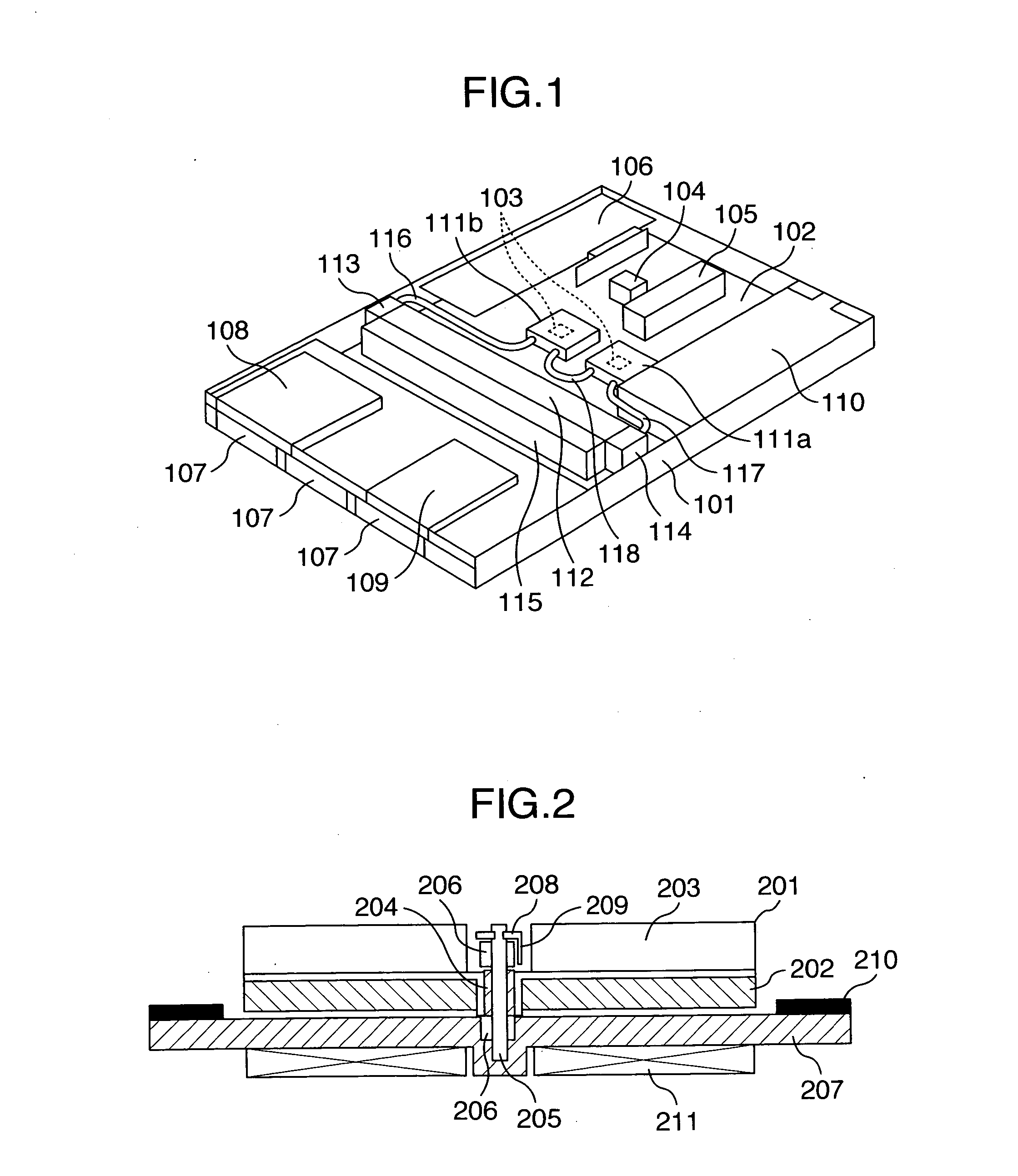

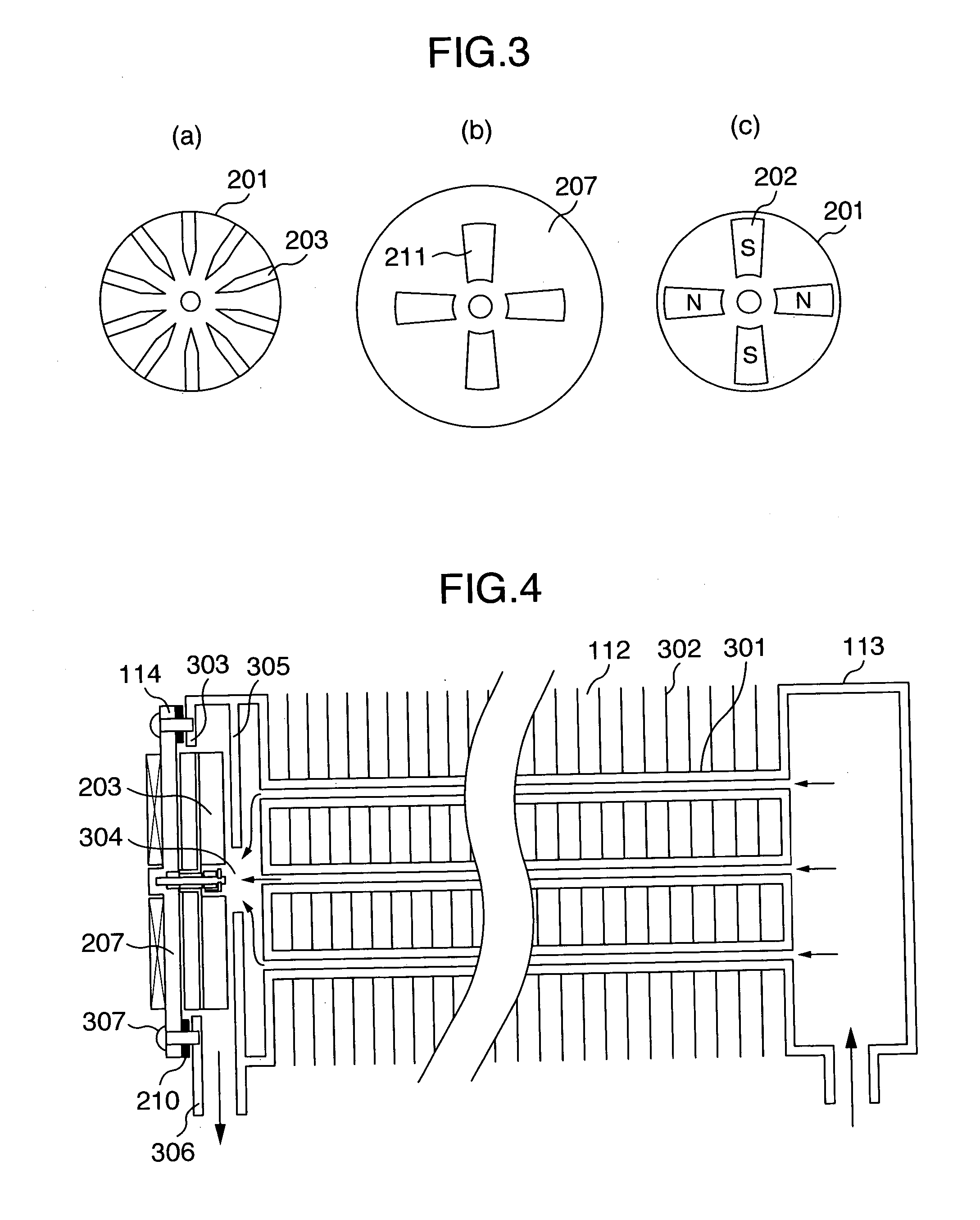

[0026]FIG. 1 is a perspective view illustrating an example of a configuration of an electronic device to which a liquid cooling system is applied according to an embodiment of the present invention, where a reference symbol 101 is a casing, a reference symbol 102 is a mother board, a reference symbol 103 is a CPU, a reference symbol 104 is a chip set, a reference symbol 105 is a memory, a reference symbol 106 is a PCI board, a reference symbol 107 is a HDD, a reference symbol 108 is a CD-ROM, a reference symbol 109 is FDD, a reference symbol 110 is a power supply unit, reference symbols 111a, 111b are jackets, a reference symbol 112 is a radiator, a reference symbol 113 is a tank section, a reference symbol 114 is a pump section, a reference symbol 115 is a fan, and reference symbols 116 to 118 are tubes. The electronic device illustrated in FIG. 1 is an approx. 44.4 high slim server, that is, a 1U server as an example.

[0027] The server as the electronic device illustrated in FIG. ...

second embodiment

[0047]FIG. 5 is a sectional view illustrating a configuration of a liquid cooling system according to a second embodiment. Referring now to FIG. 5, the liquid cooling system according to this embodiment is described below. The liquid cooling system illustrated in FIG. 5 is constructed by installing a pump section on an independent tank section. In FIG. 5, a reference symbol 401 is a tank, reference symbols 402, 403 are ports, a reference symbol 404 is a wall surface, a reference symbol 405 is a hole, and a reference symbol 406 is a partition plate. Other symbols are the same as in FIGS. 1 to 4. An arrow indicated in FIG. 5 shows a flow of coolant.

[0048] In FIG. 5, the tank 401 is made of metal, the bottom surface of the tank 401 has the holed wall surface 404 for mounting the pump section 114 thereon, where the pump section 114 is assembled. The vanes 203 of the pump section 114 are positioned inside the wall surface 404. The pump section 114 is fixed on the wall surface 404 by the...

third embodiment

[0057]FIG. 6 is a sectional view illustrating a configuration of a liquid cooling system according to a third embodiment. Referring to the drawing, a liquid cooling system according to this embodiment is described. The liquid cooling system illustrated in FIG. 6 is constituted by integrating the pump section with a radiator. In FIG. 6, a reference symbol 501 is a jacket, reference symbols 502, 503 are ports, a reference symbol 504 is a wall surface, a reference symbol 505 is a hole, a reference symbol 506 is a duct, a reference symbol 507 is an opening section, and a reference symbol 508 is a heat sink. Other symbols are the same as in FIGS. 1 and 2. An arrow indicated in FIG. 6 shows a flow of coolant.

[0058] In FIG. 6, the jacket 501 is formed out of metal with excellent thermal conductivity, such as copper or aluminum. Onto the bottom surface of the jacket 501, a heat generating body to be cooled such as a CPU is jointed through thermal conductivity grease or the like. On the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com