Carbonylation reacting kettle

A technology of carbonylation reaction and reaction kettle, which is applied in the field of carbonylation reaction kettle, can solve the problems of not being able to effectively drive the reaction mixture, and cannot realize the smooth progress of the reaction mixture, so as to improve efficiency and yield, uniform distribution, and shorten the running distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

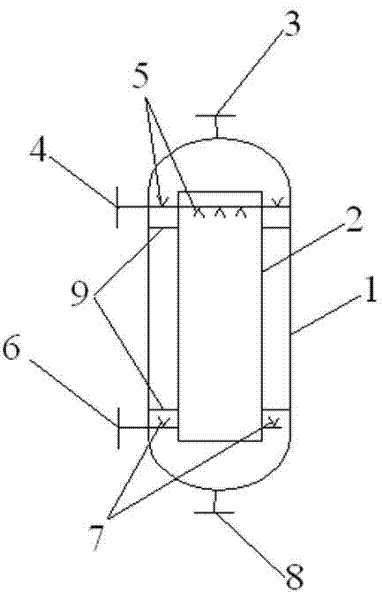

[0032] Carbonylation reactor structure of the present invention such as figure 1As shown, it includes: a kettle body 1, a partition 2 is arranged inside the kettle body 1, and the partition 2 takes the axis of the kettle body 1 as the central axis to surround and connect to form a cylinder, and the partition 2 Fix by four support rods 9 symmetrically connected on the side wall of the kettle body 1, the cylindrical area surrounded by the partition plate 2 is a descending zone, and an ascending zone is formed between the outer wall of the partition plate 2 and the inner wall of the kettle body 1, The two ends of the ascending zone and the descending zone are communicated. The inner diameter ratio of the kettle body 1 and the descending zone is 1.5-2. The bottom of the kettle body 1 is provided with a liquid outlet 8 for discharging the liquid generated by the reaction. The top of the kettle body 1 is provided with a There is a gas outlet 3 for discharging reaction tail gas and u...

Embodiment 2

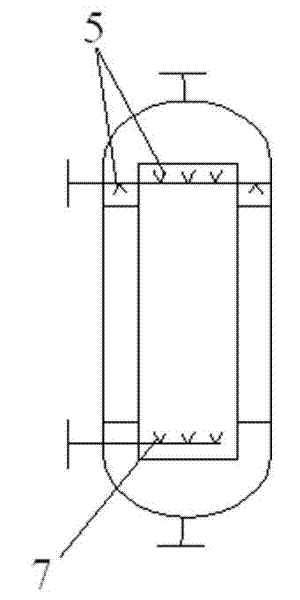

[0034] The structure of the carbonylation reactor described in this embodiment is as follows: figure 2 As shown, it includes: the cylindrical area surrounded by the partition plate 2 is an uplink zone, a downlink zone is formed between the outer wall of the partition plate 2 and the inner wall of the kettle body 1, and the two ends of the uplink zone and the downlink zone are connected, and the kettle body 1 and the inner diameter ratio of the ascending area is 1.5-2, and the liquid distributor is symmetrically provided with 5 liquid injection ports 5 opening upwards with the axis of the kettle body 1 as the center in the ascending area, and the axis of the kettle body 1 is centered in the descending area. The center is symmetrically provided with 4 liquid injection ports 5 opening downwards, and the gas distributor is provided with 5 gas injection microholes 7 opening upwards symmetrically with the axis of the kettle body 1 in the uplink area; the structures and embodiments o...

Embodiment 3

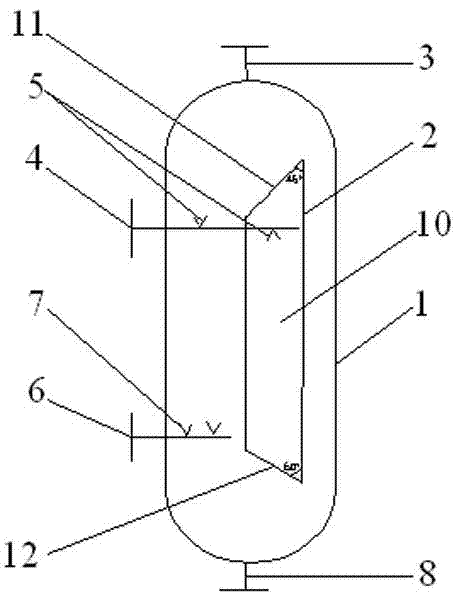

[0036] The structure of the carbonylation reactor described in this embodiment is as follows: image 3 , 4 As shown, comprising: still body 1, there is a clapboard 2 that is arc-shaped curved surface in the said kettle body 1 and is connected with described kettle body 1 inner wall, starts from the upper end of divider plate 2 and still body 1 joint simultaneously The first opening section 11 is formed downwardly, the angle between the first opening section 11 and the axis of the kettle body 1 is 45°, and it starts to slope upward from the junction of the lower end of the partition plate 2 and the kettle body 1 A second opening section 12 is formed, and the angle between the second opening section 12 and the axis of the kettle body 1 is 60°; the arc-shaped area 10 surrounded by the inner wall of the partition plate 2 and the inner wall of the kettle body 1 is a descending area , the area formed by the outer wall of the partition plate 2 and the inner wall of the kettle body 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com