Three-dimensional automatic container wharf

A container and container yard technology, applied in the field of automated terminals, can solve the problems of reducing the running distance and time of receiving and dispatching boxes, affecting the construction of automated terminals, shortening the collection port, etc., so as to reduce the construction land of the terminal, improve the operation efficiency, and reduce the running distance. and time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

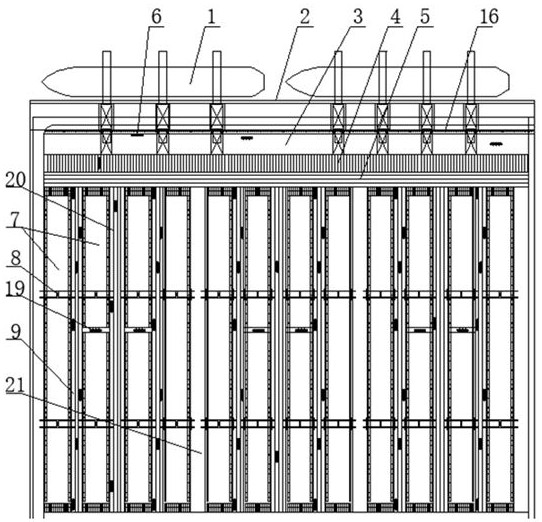

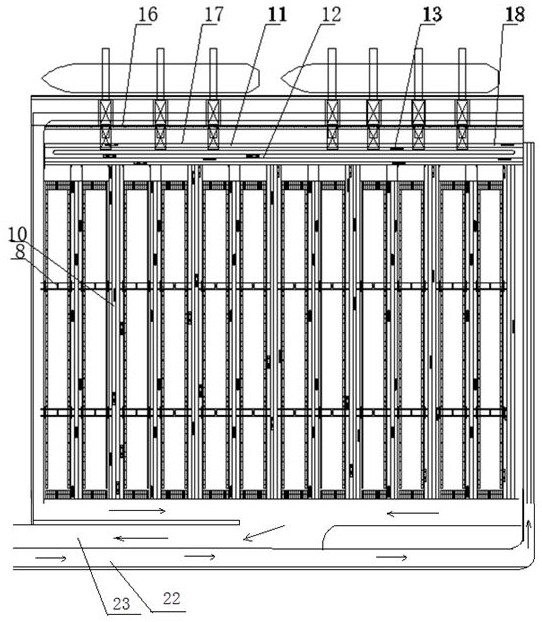

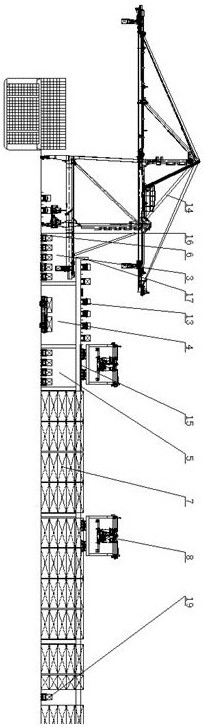

[0016] The three-dimensional automated container terminal proposed by the present invention, such as Figure 1 to Figure 4 shown, including:

[0017] Wharf 2 is used to dock ships 1 and is arranged along the shore.

[0018] The quay bridge 14 is used for container loading and unloading operations on the quay shoreline, and is arranged along the shoreline of the front quayside of the quay 2.

[0019] The container yard 7 is divided into upper and lower floors, and is composed of several container areas arranged vertically to the shoreline of the wharf and an automatic double-cantilever gantry crane 8 mounted on the upper part of the container area; among them, the lower layer includes automated double-cantilever cranes parallel to the container area. Cantilever gantry crane and automated horizontal transport equipment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com