Steam catapult booster for aircraft takeoff

An aircraft take-off and steam technology, which is applied in the direction of launch/tug transmission device, etc., can solve the problems of difficult to achieve boost force, small ejection force, insufficient continuous steam thrust, etc., and achieves short take-off time, large ejection thrust, and low material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

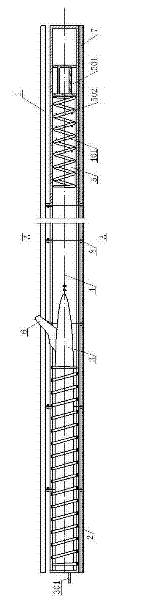

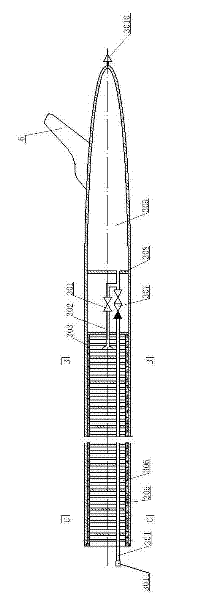

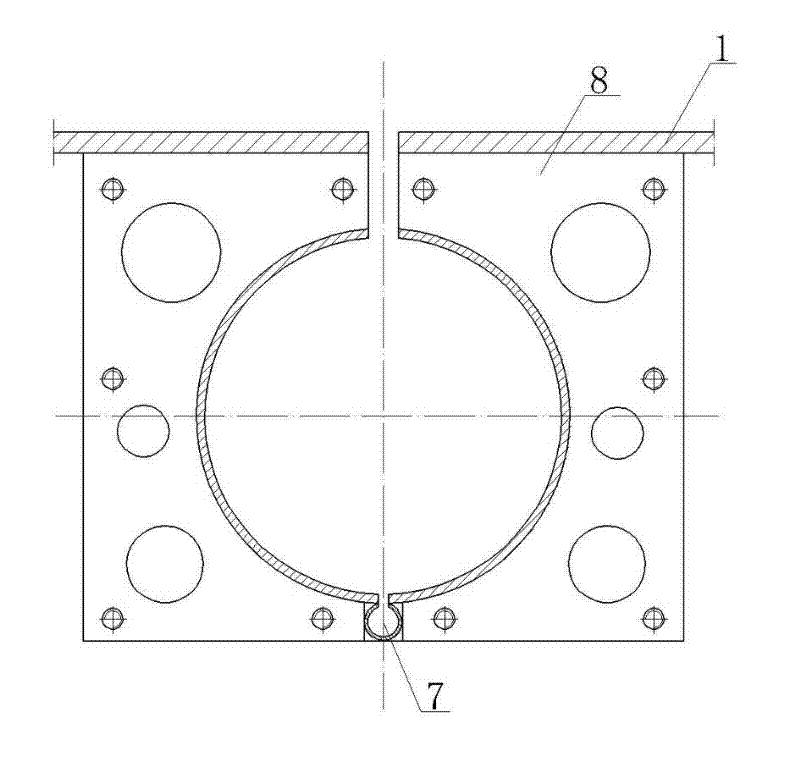

[0027] like Figure 1 to Figure 5 As shown, the aircraft take-off steam ejection booster includes a flight deck 1, and a sliding pipeline 4 is fixed below the flight deck 1. The sliding pipeline 4 is multi-section, and each section is connected by a flange 8, and the sliding pipeline 4 Weld with the flight deck 1 through the flange 8 . A steam catapult booster 3 is placed at the inner rear of the gliding duct 4, an aircraft connector 6 is arranged on the upper surface of the steam catapult booster 3, and a gap is provided on the flight deck 1 and the gliding duct 4 corresponding to the position of the aircraft connector 6 , the aircraft connector 6 is drawn out from the slit and can slide along the slit, and a deceleration reset device 5 is provided at the front of the slide pipe 4, and the deceleration reset device 5 is fixed on the piston 501 by the piston 501 The buffer return spring 502 on the side opposite to the steam ejection booster 3 is formed, and an exhaust hole 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com