Robot welding workstation for low-temperature tank external components

A robot welding and workstation technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the degree of automation, welding quality and work efficiency are difficult to be competent for complex welding conditions, effects and time spent Satisfactory and other issues, to achieve the effect of improving work efficiency and quality, improving welding quality, and reducing running distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

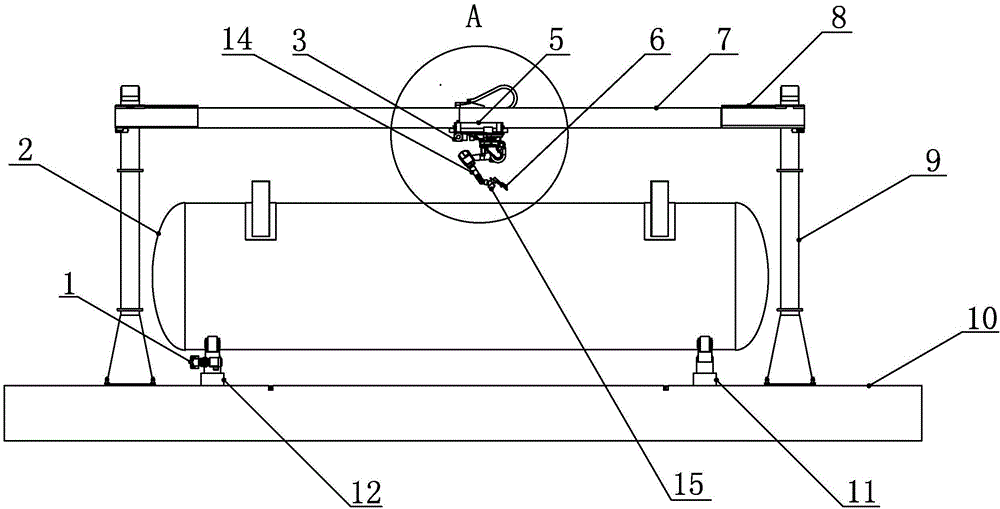

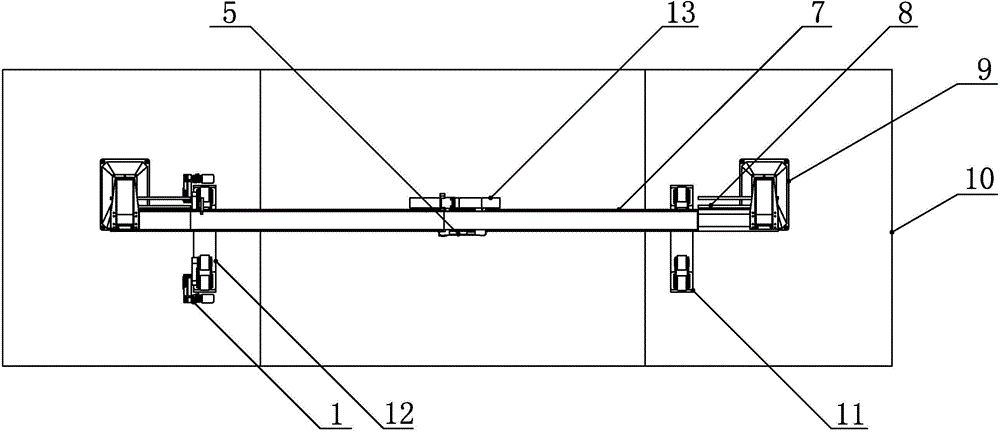

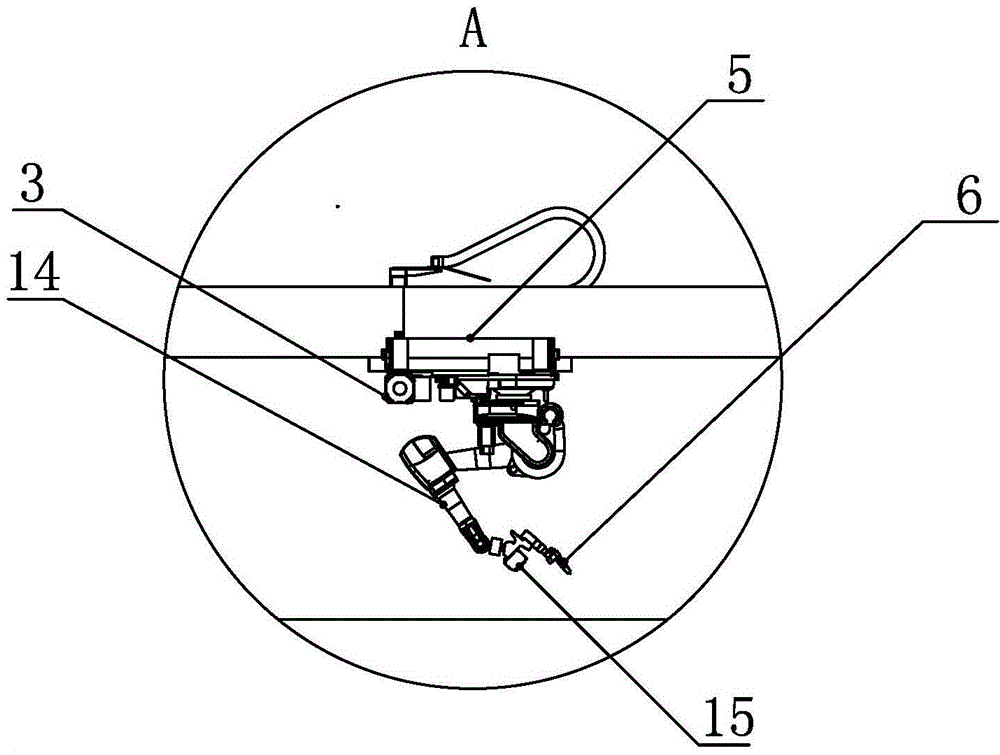

[0020] Such as Figure 1 ~ Figure 4 As shown, a robot welding workstation for low-temperature tank external parts of the present invention includes a workbench 10 on which a welding system 21 and a control system 24 are arranged. The welding system 21 includes a gantry 9, a rack is provided on the horizontal guide rail 7 of the gantry 9, and limit blocks 8 are provided at the left and right ends of the horizontal guide rail 7. The horizontal guide rail 7 is movably equipped with a side-hanging traveling mechanism, and the side-hanging traveling mechanism includes a robot installation base 5 . Such as image 3 As shown, a servo motor 3 is installed on the robot mounting base 5, and a gear is installed on the output shaft of the servo motor 3, and the gear matches the rack on the horizontal guide rail 7, thereby driving the robot mounting base 5 to move left and right on the horizontal guide rail 7. Such as figure 1 , figure 2 and image 3 As shown, a buffer block 13 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com