Coal-gas recovering process and device of charging, equalizing and bleeding of blast furnace

A blast furnace charging and top gas technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., to achieve the effects of simple structure, relief of environmental pressure, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be described in detail below in conjunction with the examples.

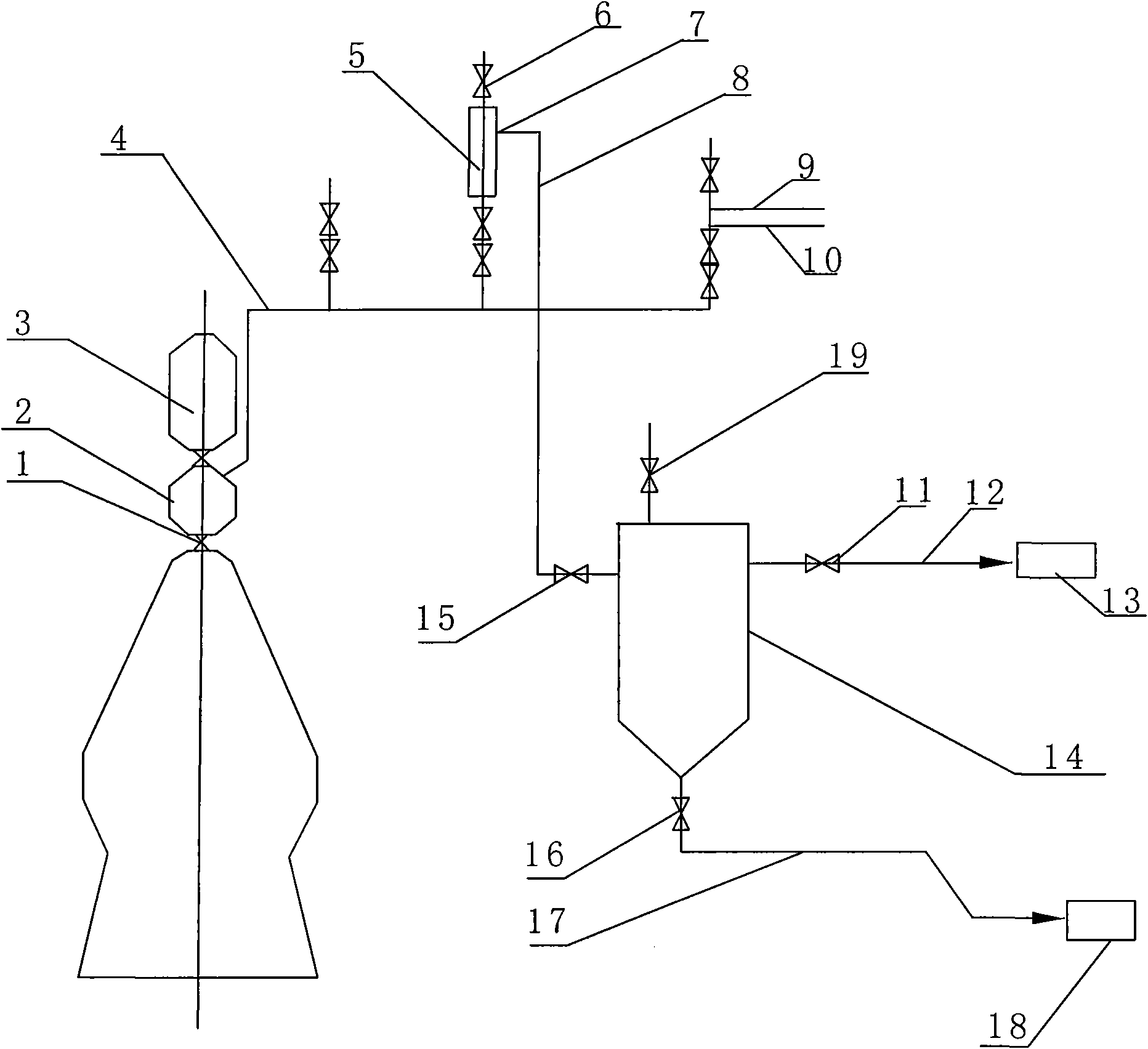

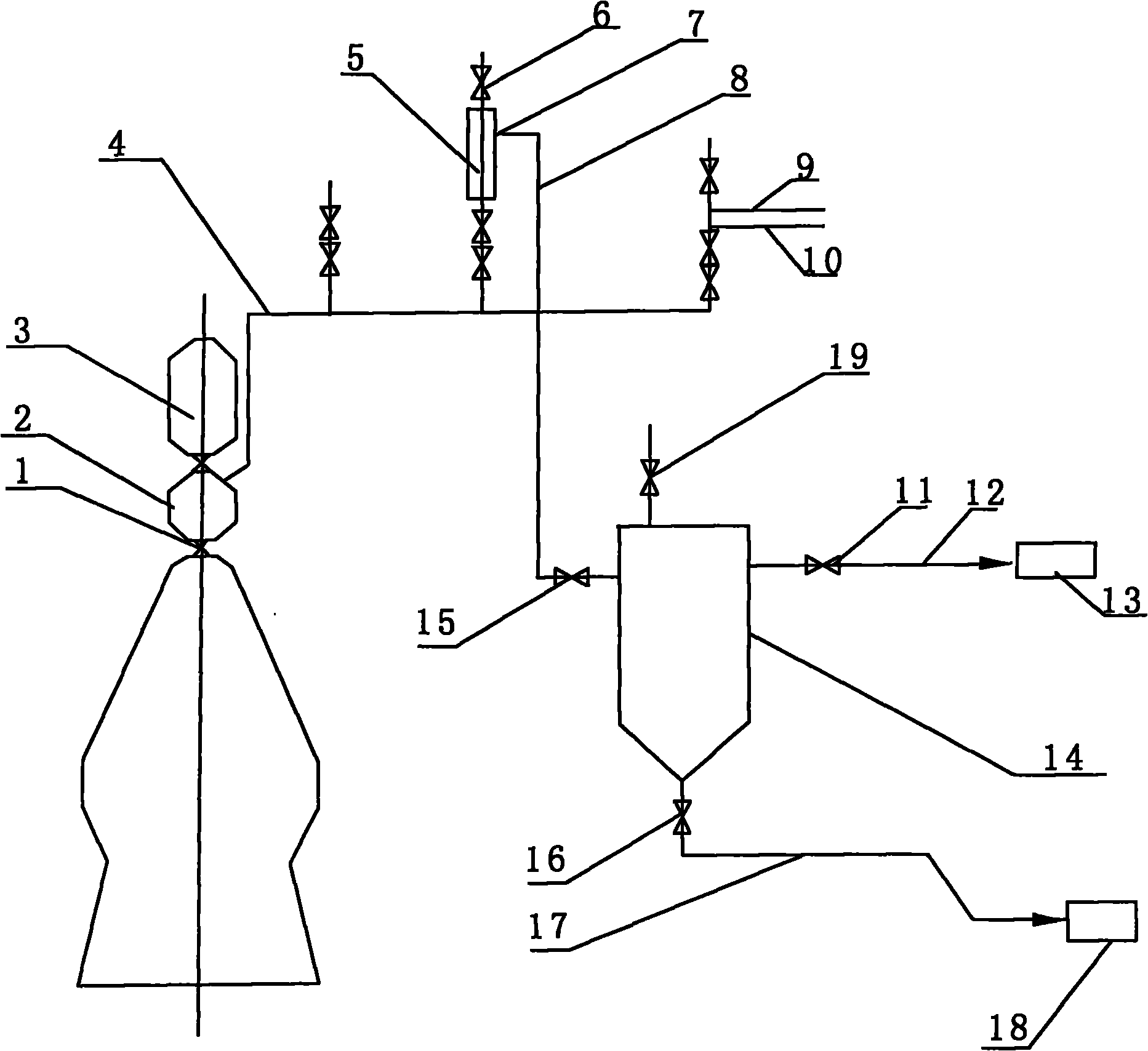

[0014] Such as figure 1 Shown, the gas recovery process of blast furnace charge equalization pressure release process of the present invention is characterized in that:

[0015] A. The raw gas released from the blast furnace charging system's lower material tank 2 through the release pipeline 4 enters the furnace top gas silencer cyclone dust collector 5, closes the cut-off valve 6 installed on the furnace top gas silencer cyclone dust collector 5, and opens Semi-clean gas cut-off valve 15, the semi-clean gas formed after preliminary dedusting by furnace top gas silencer cyclone dust collector 5, the semi-clean gas enters the bag filter through semi-clean gas pipeline 8 and semi-clean gas cut-off valve 15 14,

[0016] B. Open the shut-off valve 11 of the gas pipe network, and the clean gas after fine dust removal by the bag filter 14 enters the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com