Drop-off fusible cut-out without power-cut

A technology of drop-out fuses and electrical connectors, which is applied in circuits, electrical components, electric heat release switches, etc., to achieve the effects of quick maintenance, large contact surface, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

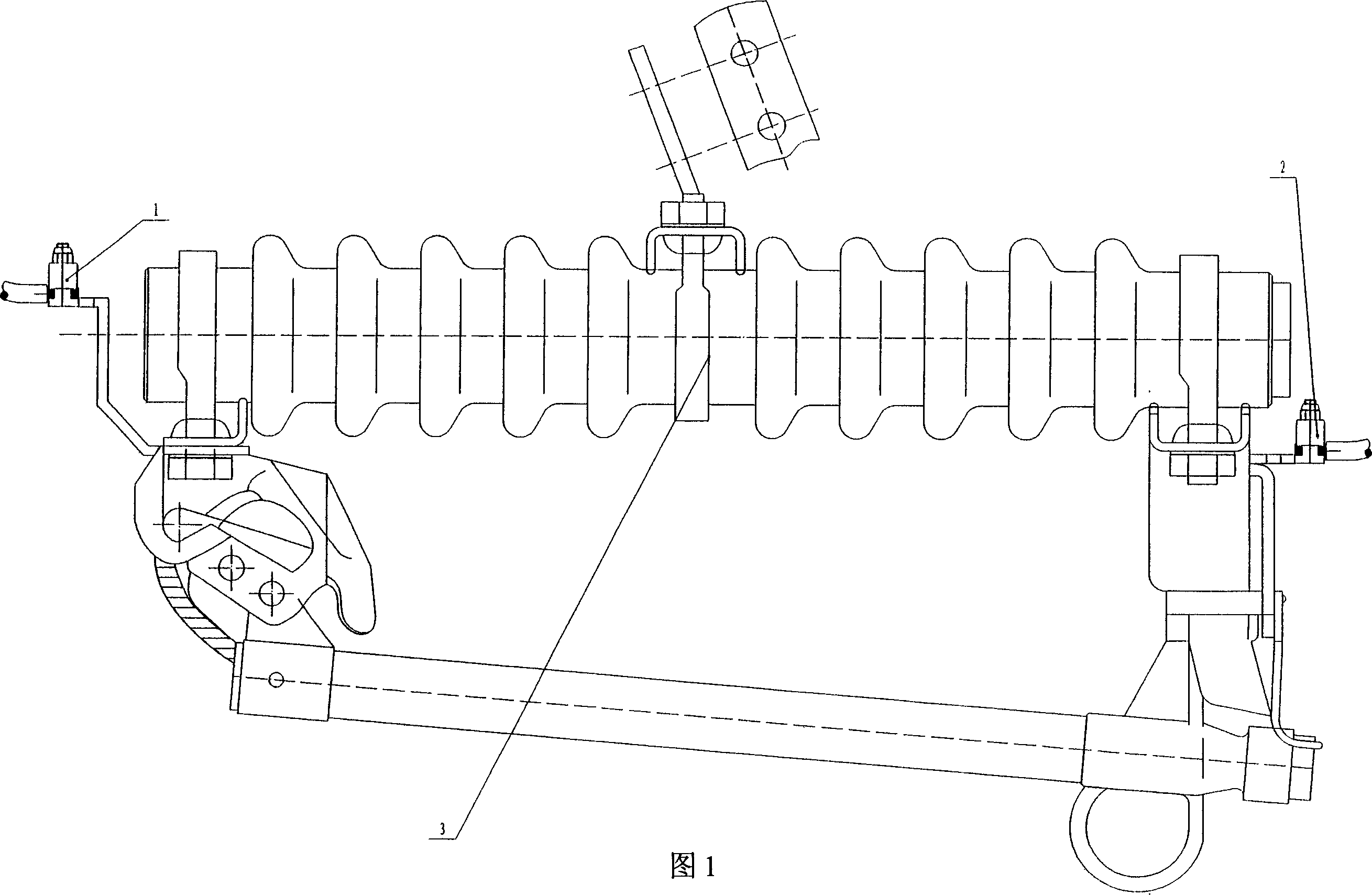

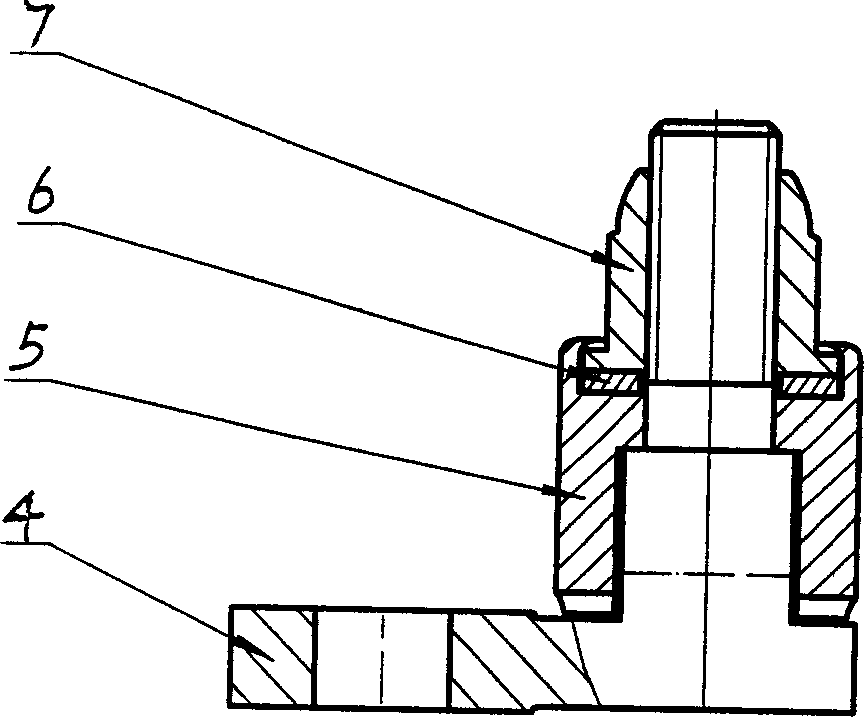

[0010] The present invention is mainly composed of clip-type synchronous electrical connectors 1 and 2, drop-out fuse body 3, connector body 4, clip block seat 5, full-circle anti-loosening gasket 6, flange nut 7 and the like.

[0011] In the present invention, a clip-type synchronous electrical connector 1 and a clip-type synchronous electrical connector 2 are respectively installed at both ends of the drop-out fuse body 3 .

[0012] The clamp-type synchronous electrical connectors 1 and 2 of the present invention are respectively composed of a connector body 4 , a clamping block seat 5 , a full circle anti-loosening washer 6 and a flange nut 7 . The lower part of the connector body 4 is a threading hole, and the upper part is a bolt structure, which is composed of a flange nut 7, a full-circle anti-loosening washer 6, and a clamping block seat 5 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com