Broaching machine special for horizontal machining air cylinder

A cylinder block and horizontal technology, applied to broaching machines, broaching devices, metal processing equipment, etc., can solve the problems of low production efficiency, high labor intensity, time-consuming and laborious, etc., achieve convenient maintenance and installation, improve production efficiency and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

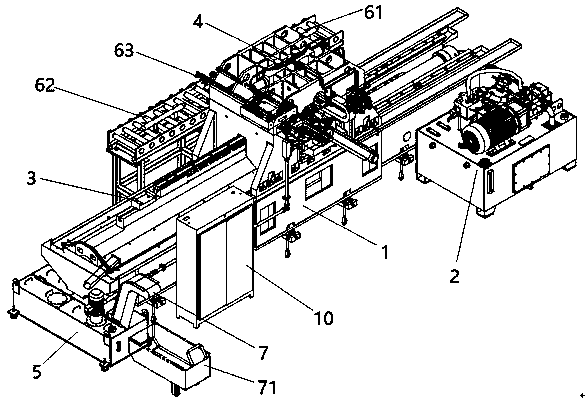

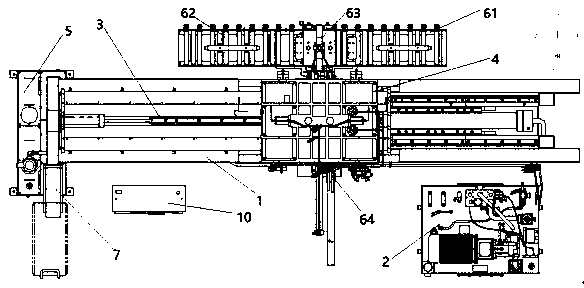

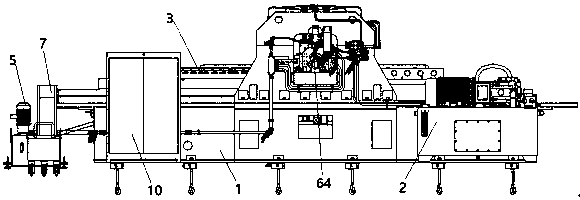

[0022] Such as Figure 1-4 As shown, the embodiment of the present invention is a special broaching machine for horizontal processing of cylinder blocks, including a bed 1, a hydraulic system 2, a tool system 3, a fixture system 4, a loading and unloading system, a cooling system 5, and a chip removal system And electrical control system, bed 1 is respectively connected with hydraulic system 2, tool system 3, fixture system 4, loading and unloading system, cooling system 5, chip removal system and control system, and described bed 1 is horizontal and rectangular, There is a main slide plate on it, and the main slide plate can be driven by an oil cylinder to move horizontally along the long axis of the bed 1; the tool system 3 includes a broach and a tool holder, and the broach is fixed on the main slide plate through the tool holder. The tool seat is made of high-strength and high-rigidity materials; the cooling system 5 is connected to the chip removal system and is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com