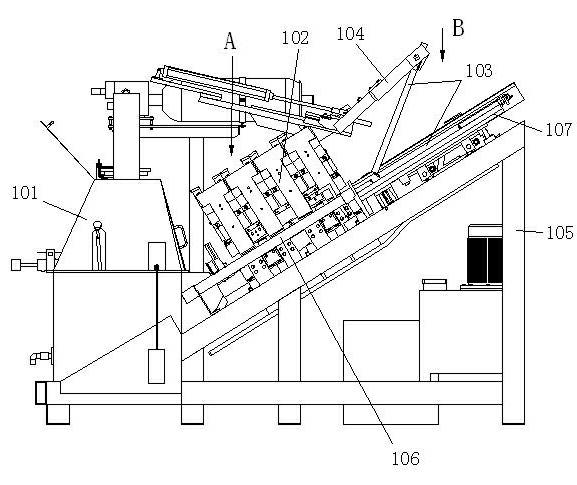

Plate grid ejection mechanism of lead-acid battery plate grid die casting machine

A technology of lead-acid battery and ejection mechanism, which is applied in the field of grid ejection mechanism, which can solve the problems that the action timing of the ejection mechanism cannot be changed, the ejection speed of the grid cannot be adjusted, and the ejection of the grid is not complete, etc., so as to achieve a stable The effect of ejection, simple structure and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

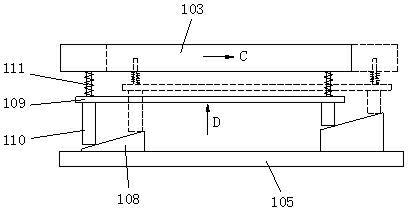

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown. This invention may, however, be embodied in many different forms and should not be construed as limited to the exemplary embodiments set forth herein.

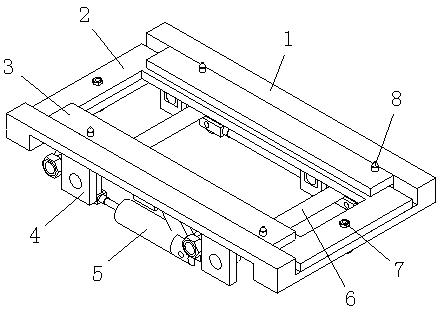

[0032] Such as Figure 3-8As shown, the grid ejection mechanism of the lead-acid battery grid die-casting machine of the present invention includes a fixed frame 1 and a moving frame; wherein, the moving frame includes a rectangular seat plate 2 and two thimble plates 3 arranged on it, and two thimble plates 3 Fixed on the seat plate 2 at intervals along the width direction of the mold 103, each thimble plate 3 is arranged along the length direction of the mold 103 with a row of thimble pins 8 corresponding to the thimble jacks on the fixed template of the mold 103; the fixed frame 1 is also rectangular , the upper surface of the two short sides is lower than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com