Rubber and plastic spring vibration reduction device for large coal mill base and foundation and using method of rubber and plastic spring vibration reduction device

A technology of shock absorption device and coal mill, applied in spring/shock absorber, lifting device, special foundation layout, etc., can solve the problems of high design cost, limited contact area, weak shock absorption effect, etc. Achieve the effect of simple structure, high safety factor and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

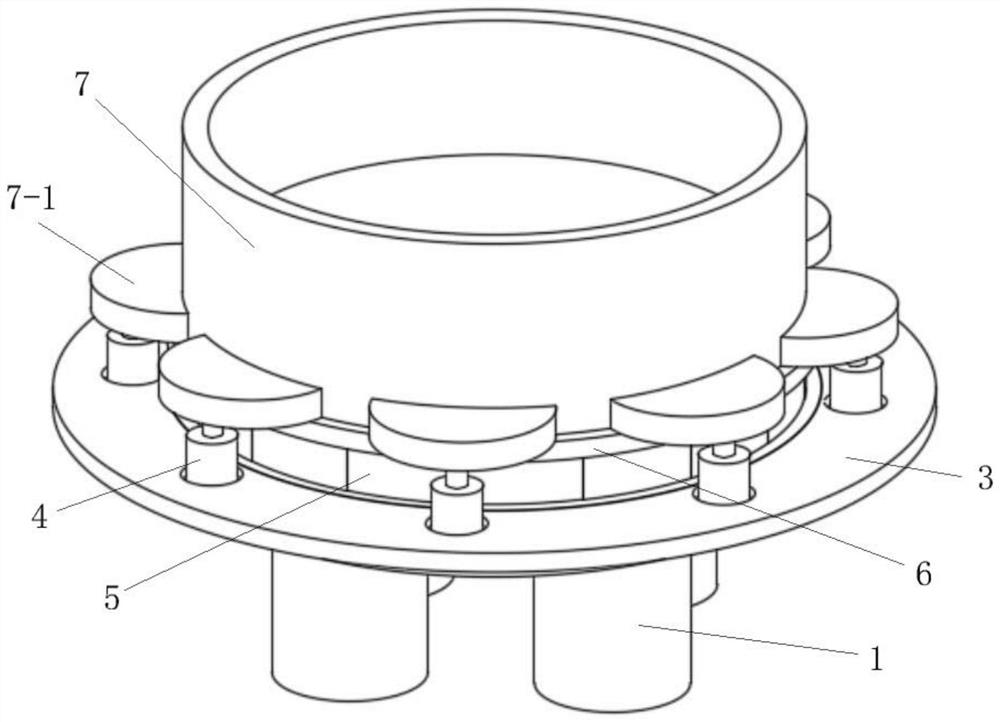

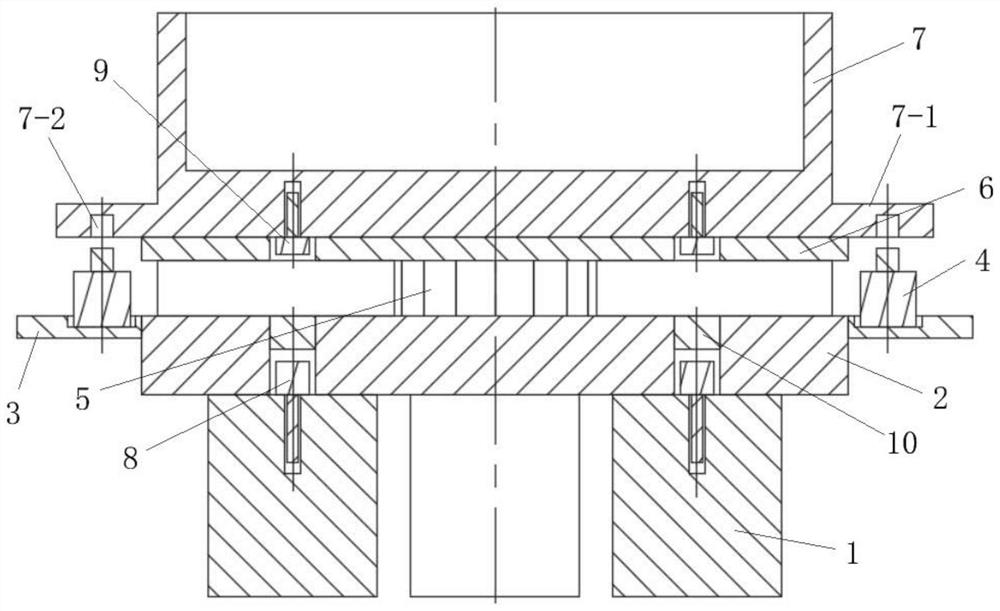

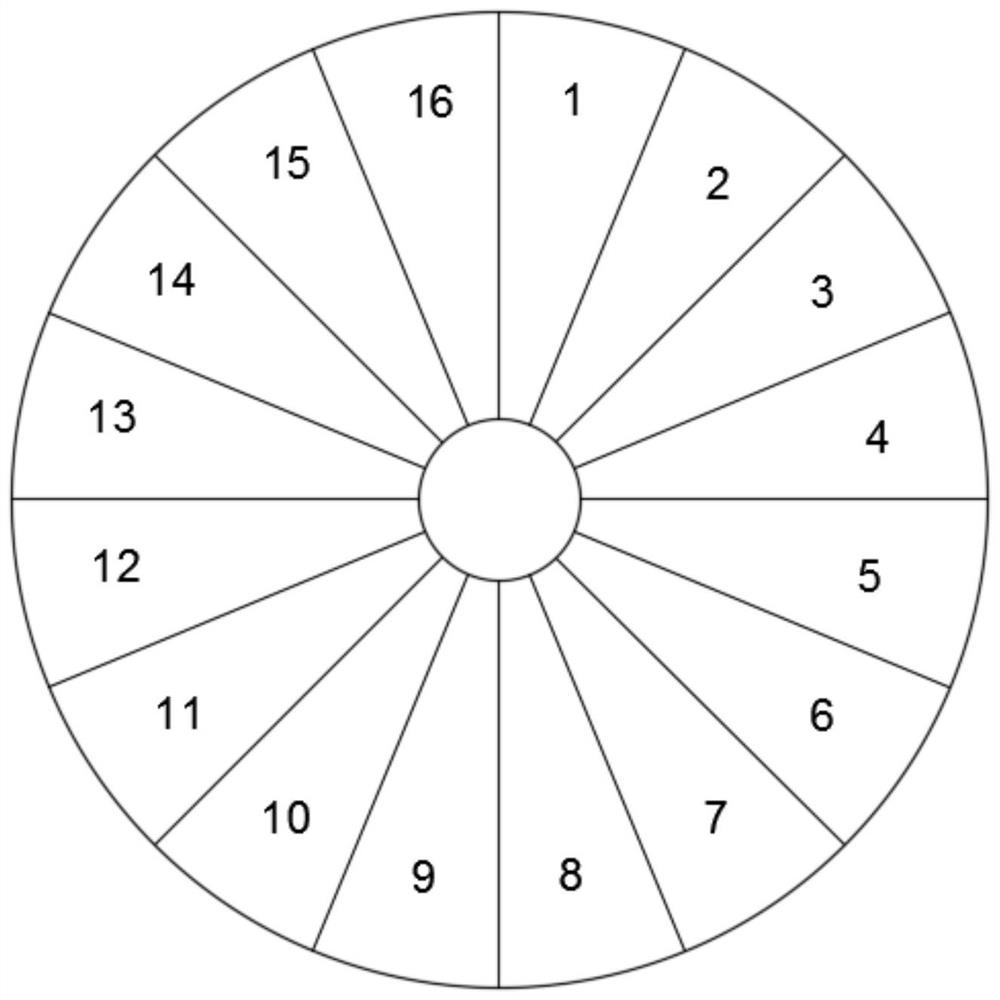

[0038] Such as Figure 1-3 As shown, a large-scale coal mill base and foundation rubber-plastic spring structure damping device of the present invention includes foundation pillar 1, spring lower bottom plate 2, jack bottom plate 3, synchronous hydraulic jack 4, rubber-plastic spring 5 and spring upper bottom plate 6. The foundation pillar 1 is poured into the foundation, and the upper bolt hole is vertically opened on the bottom plate 2 of the spring. The bottom bolt hole is correspondingly opened on the top of the foundation pillar 1, and the upper and lower bolt holes are aligned and locked by the anchor bolt 8. The lower spring bottom plate 2 is horizontally fixed on the foundation pillar 1, the jack bottom plate 3 is an annular bottom plate, and a perforation is opened in the middle of the annular bottom plate. On the bottom plate 2 under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com