Pallet stacking device for palletizing conveying line

A conveyor line and pallet technology, applied in the field of palletizing conveyor lines, can solve the problems of reduced production efficiency, complex installation and maintenance, complex structure, etc., and achieve the effects of simple structure, improved operation efficiency, and convenient maintenance and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

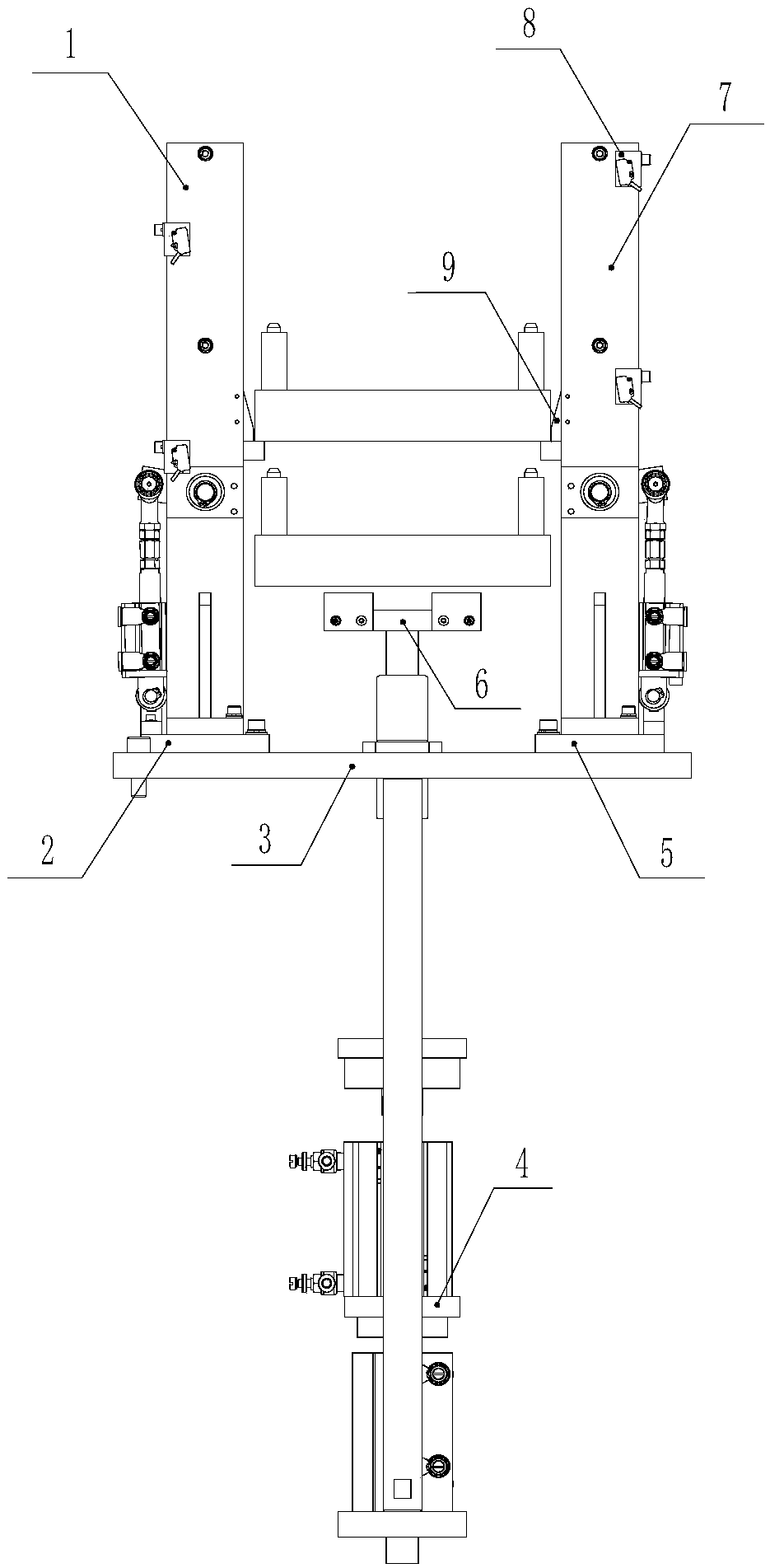

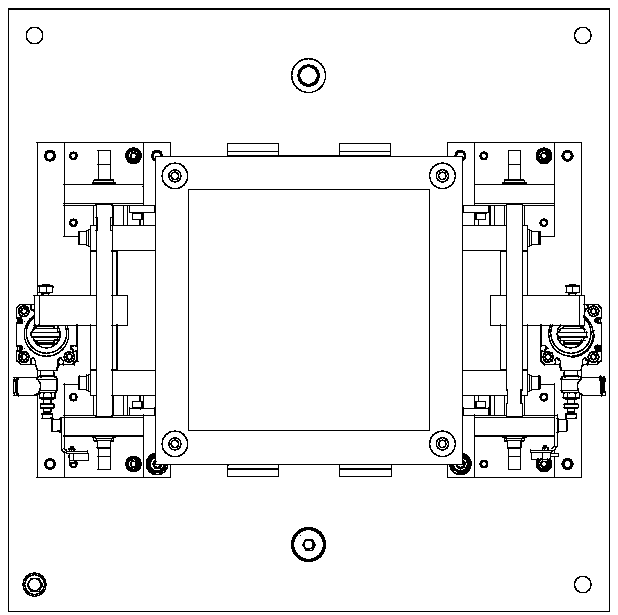

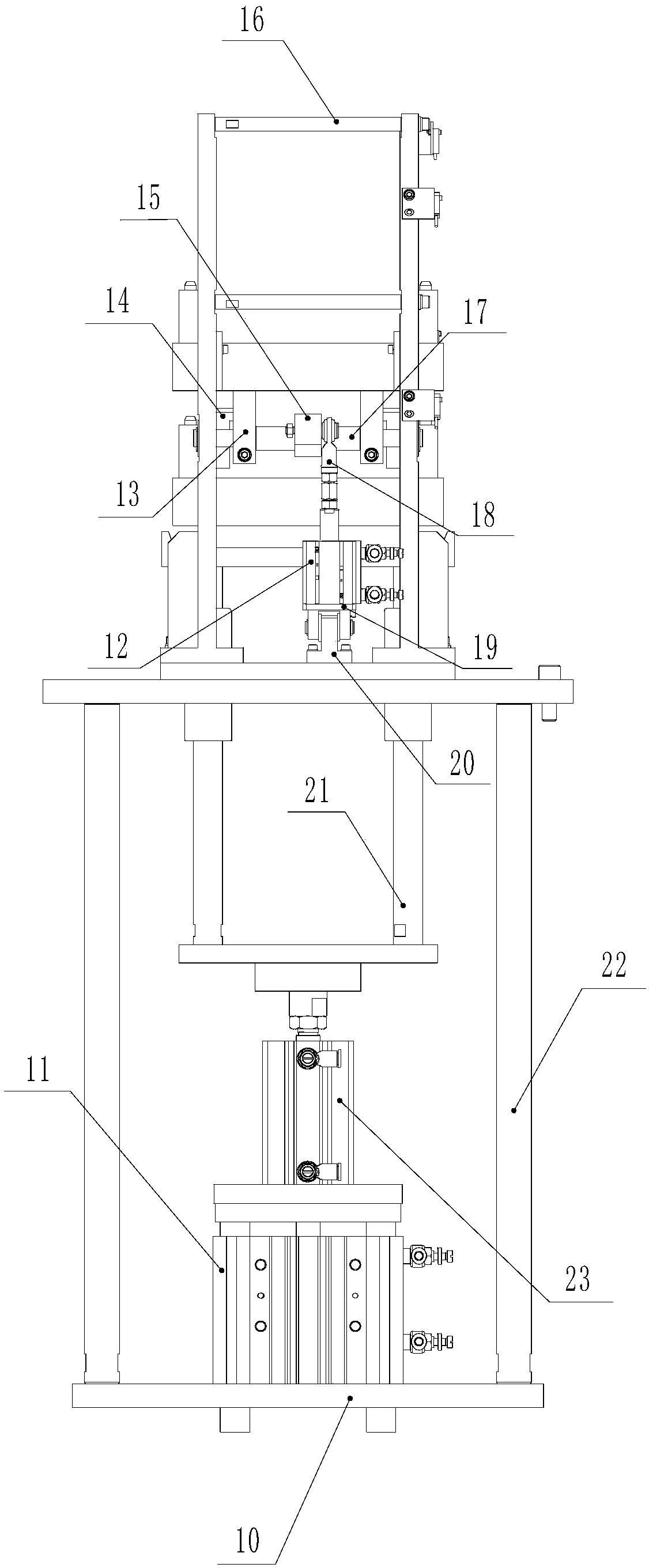

[0020] A pallet stacking device for a palletizing conveyor line, which includes a left pillar 1, a left mounting plate 2, a base 3, an adapter plate 4, a right mounting plate 5, a top plate 6, a right pillar 7, a photoelectric sensor 8, a guide plate 9, Base plate 10, cylinder with guide rod 11, left cylinder 12, left lifting block 13, left limiting block 14, left connecting block 15, left connecting rod 16, left rotating shaft 17, left joint bearing 18, left double ear seat 19, Left hinge seat 20, guide shaft 21, column 22, upper cylinder 23, floating joint 24, linear bearing 25, right cylinder 26, right rotating shaft 27, right limit block 28, right jacking block 29, right connecting rod 30, sensor Mounting bracket 31, right connecting block 32, right joint bearing 33, right double ear seat post 34, right hinge seat 35 and support 36, described base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com