Heat treatment workshop waste gas plasma purification device and purification method

A plasma and purification device technology, applied in the field of plasma purification devices, can solve the problems of incompatibility of process conditions, poor pertinence, secondary pollution, etc., and achieve strong pertinence and practicability, good purification effect, and purification efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

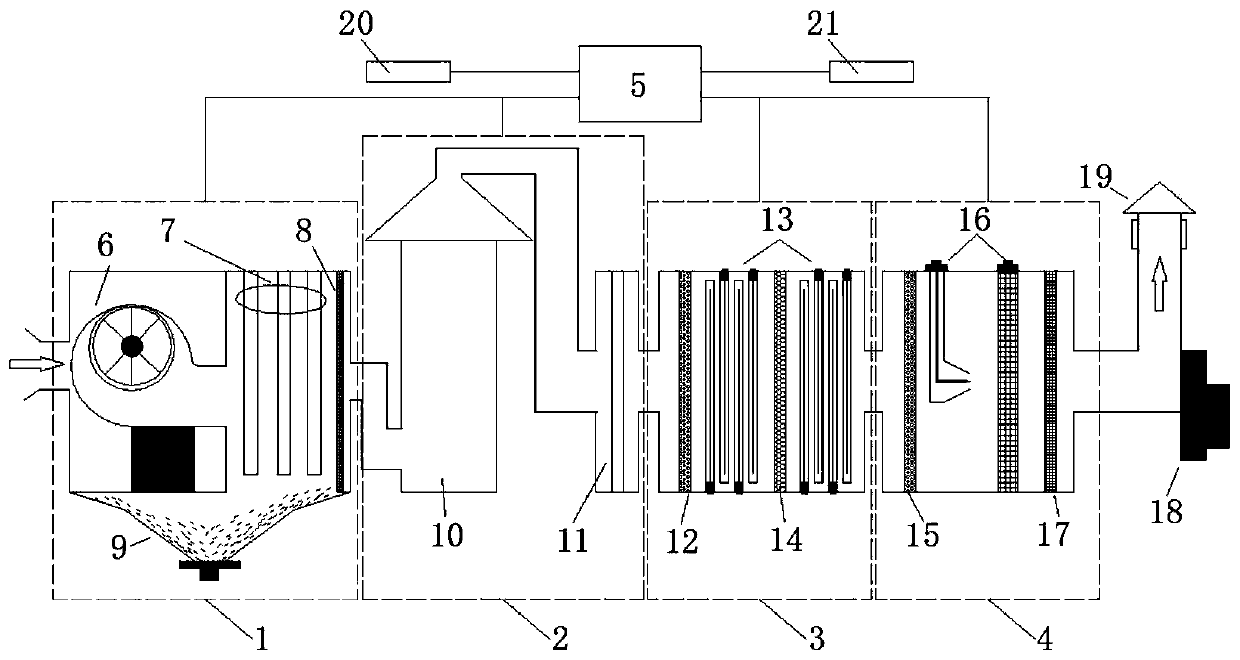

[0023] see figure 1 Description of this embodiment, a waste gas plasma purification device in a heat treatment workshop, which includes a mechanical dust removal module 1, a waste gas cleaning module 2, a plasma primary purification module 3, and a plasma secondary purification module 4 arranged in series in a horizontal direction. The mechanical dust removal module 1 performs mechanical dust removal and separation of granular smoke and dust in the exhaust gas, the exhaust gas cleaning module 2 purifies and separates water-soluble pollutants in the exhaust gas, and the plasma primary purification module 3 includes the first gas Distribution plate 12, dielectric barrier discharge assembly 13 and photolysis catalytic plate 14, the first gas distribution plate 12 is located in fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com