Modularized multi-cable via hole insulation sealing structure based on pressure compensation

A sealing structure and modular technology, applied in the direction of pipes, electrical components, pipes/pipe joints/pipe fittings, etc., can solve the problems of simple structure and small size, and achieve the effect of increasing the pressure application range, facilitating maintenance, and meeting the high-pressure sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

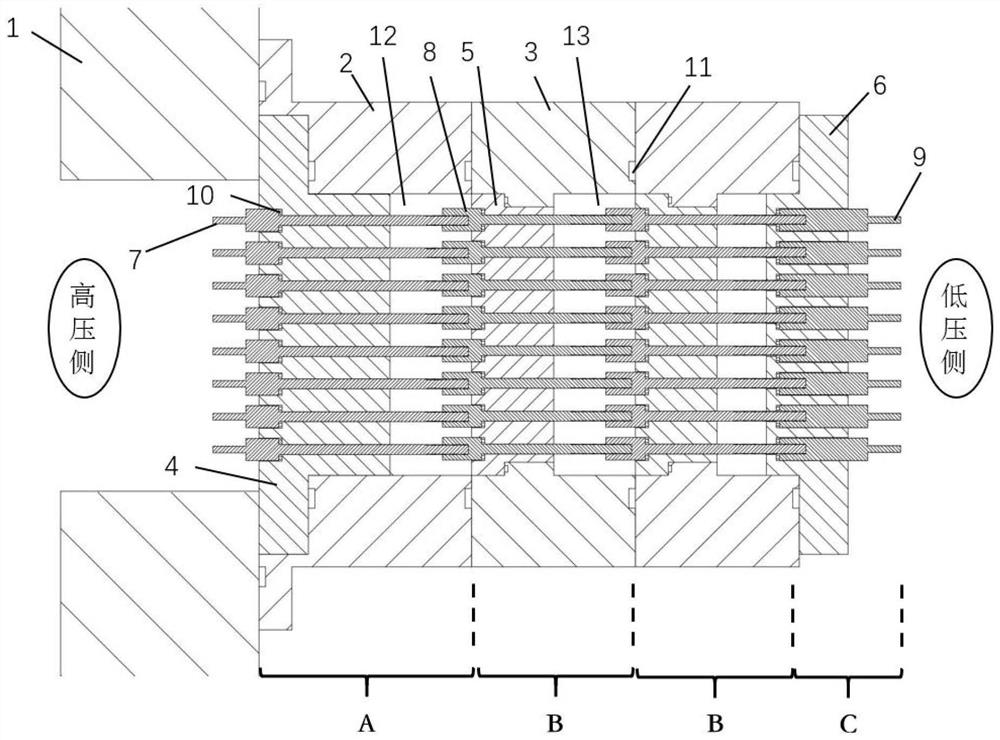

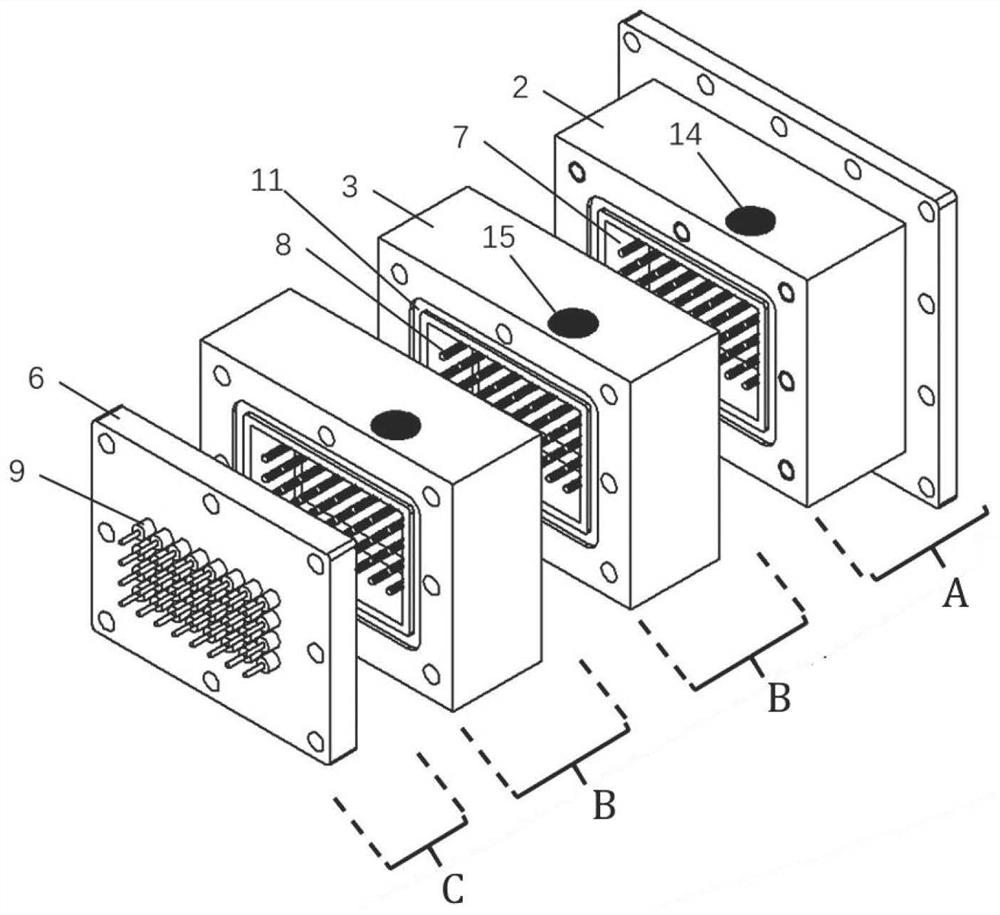

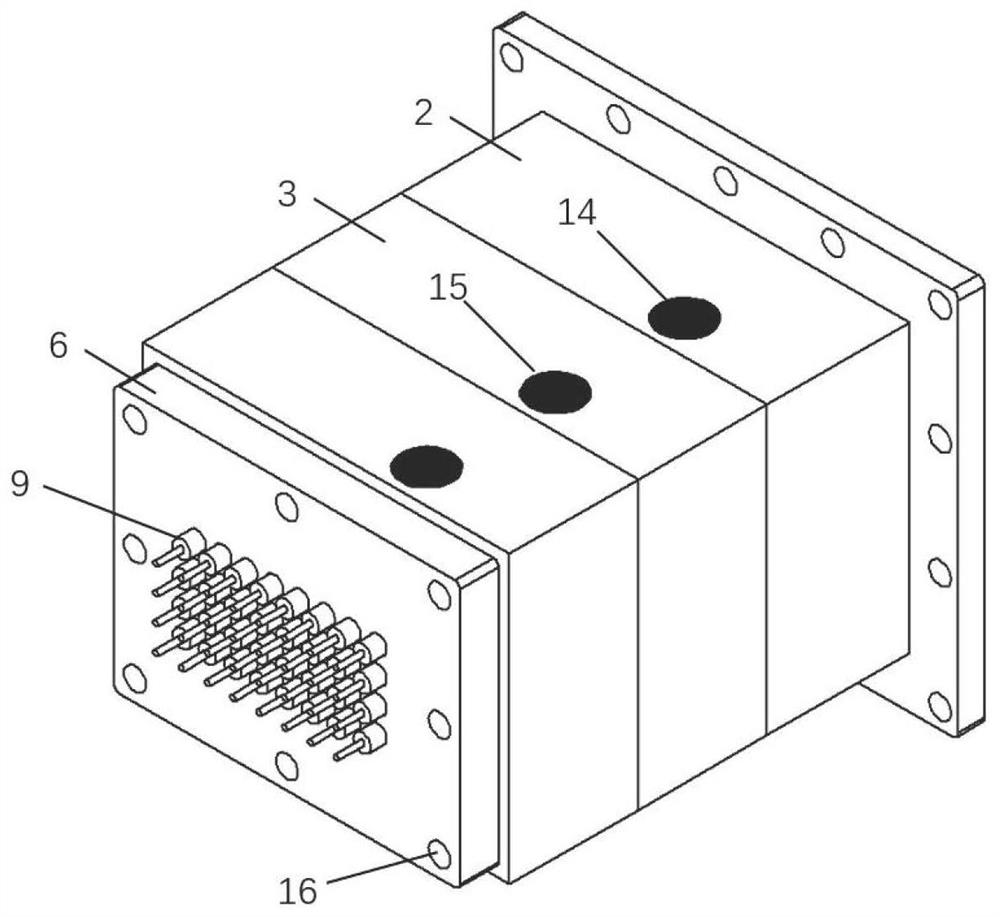

[0017] Such as figure 1 As shown, this embodiment relates to a modular multi-cable sealing structure, including: a high-voltage transition section A set on the high-voltage side, a low-voltage transition section C set on the low-pressure side, and several decompression lines arranged in series. Module B, wherein: the high-voltage transfer section A includes a high-voltage transfer bracket 2 and a high-voltage transfer base 4 with a high-voltage transfer conductor column 7 arranged inside it; the low-voltage transfer section C includes: a low-voltage transfer conductor The low-voltage transfer matrix 6 of the column 9; the decompression module B includes: a decompression module support 3 and a decompression module substrate 5 with a decompression module conductor post 8 arranged inside it, a high-voltage transfer conductor post 7, a decompression The module conductor column 8 and the low-voltage transfer conductor post 9 are sequentially connected, the high-voltage transfer bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com