Clean and environment-friendly waste gasification heat storage method and device

A clean and environmentally friendly heat storage device technology, applied in the direction of combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of high cost of construction and maintenance, unused heat energy, high cost of flue gas treatment, etc., to reduce smoke The effect of reducing gas treatment cost, improving gasification conversion efficiency, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

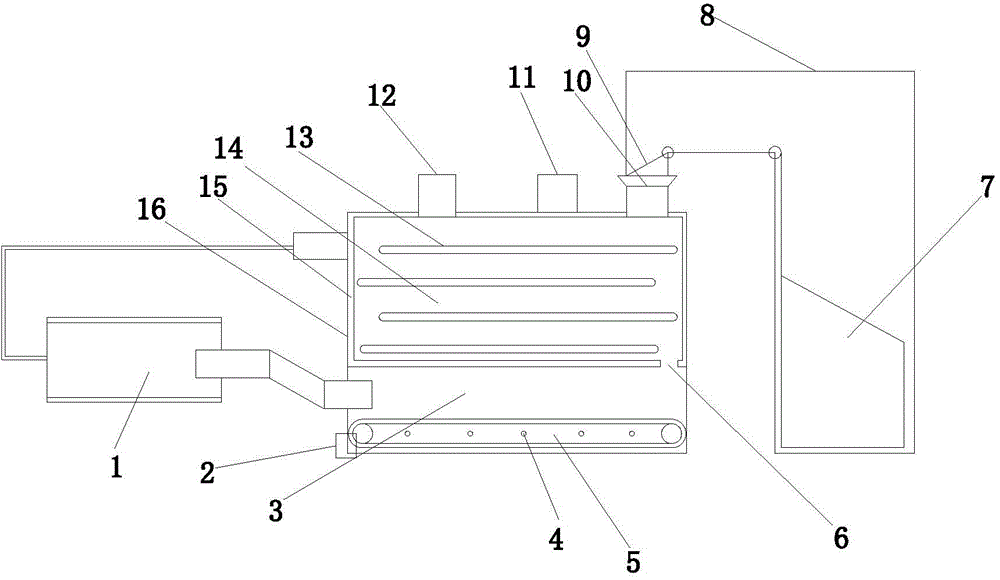

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0020] Example. Garbage gasification clean and environmentally friendly heat storage method is characterized in that: in the garbage sealed bin, the garbage is poured into the drying bin by lifting the feeding device, and after repeated drying in the drying bin, it enters the combustion bin, and the high-temperature gas after combustion is not only It enters the burner for heat storage, and performs secondary drying in the drying chamber. The combustion slag is discharged through the chain furnace pan. After the burner is used, the waste heat gas enters the jacket of the drying chamber to heat it, so that The garbage is preheated to improve the utilization rate of heat energy. After pouring the garbage into the drying bin, seal the outlet of the airtight bin through the return cover to prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com