Automatic crystal blank grinding and polishing system and butt joint machine thereof

A docking machine and docking machine technology, applied in grinding/polishing equipment, grinding machines, spherical grinding machines, etc., can solve the problems of increasing the waiting time of the machine, long moving stroke, and prolonging the occupation time, so as to reduce the waiting time of the machine, The effect of improving the service life of the equipment and reducing the time occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

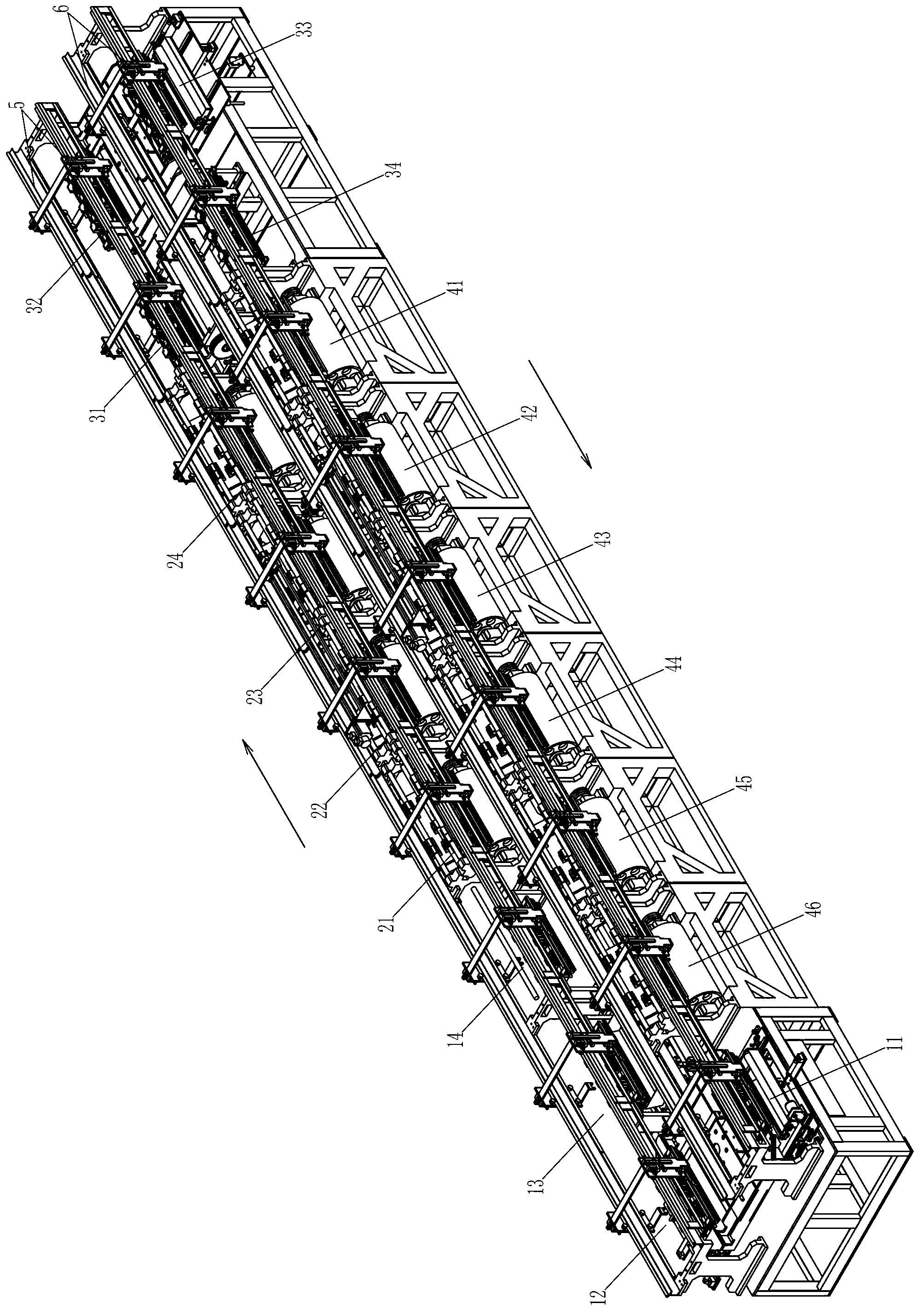

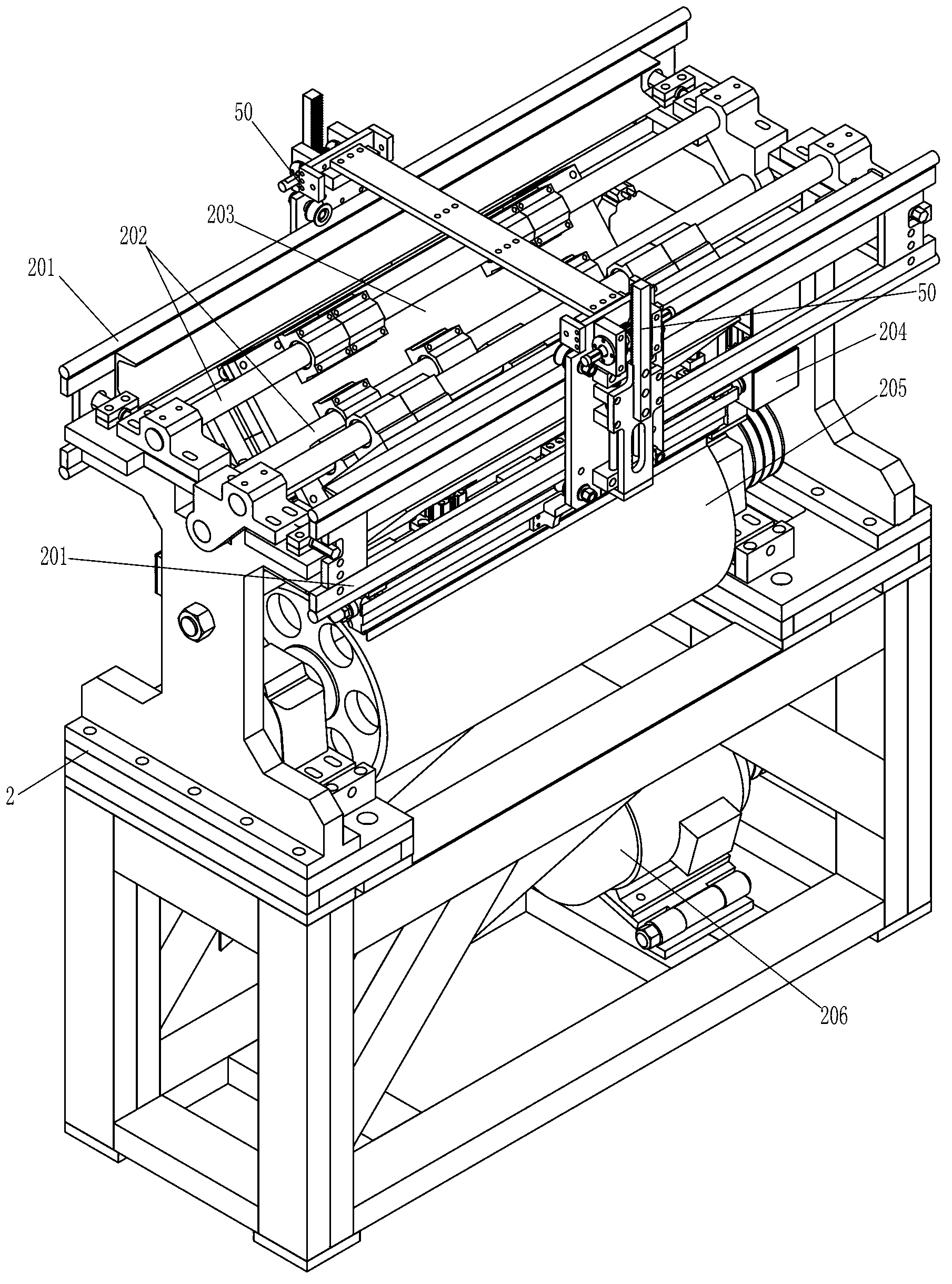

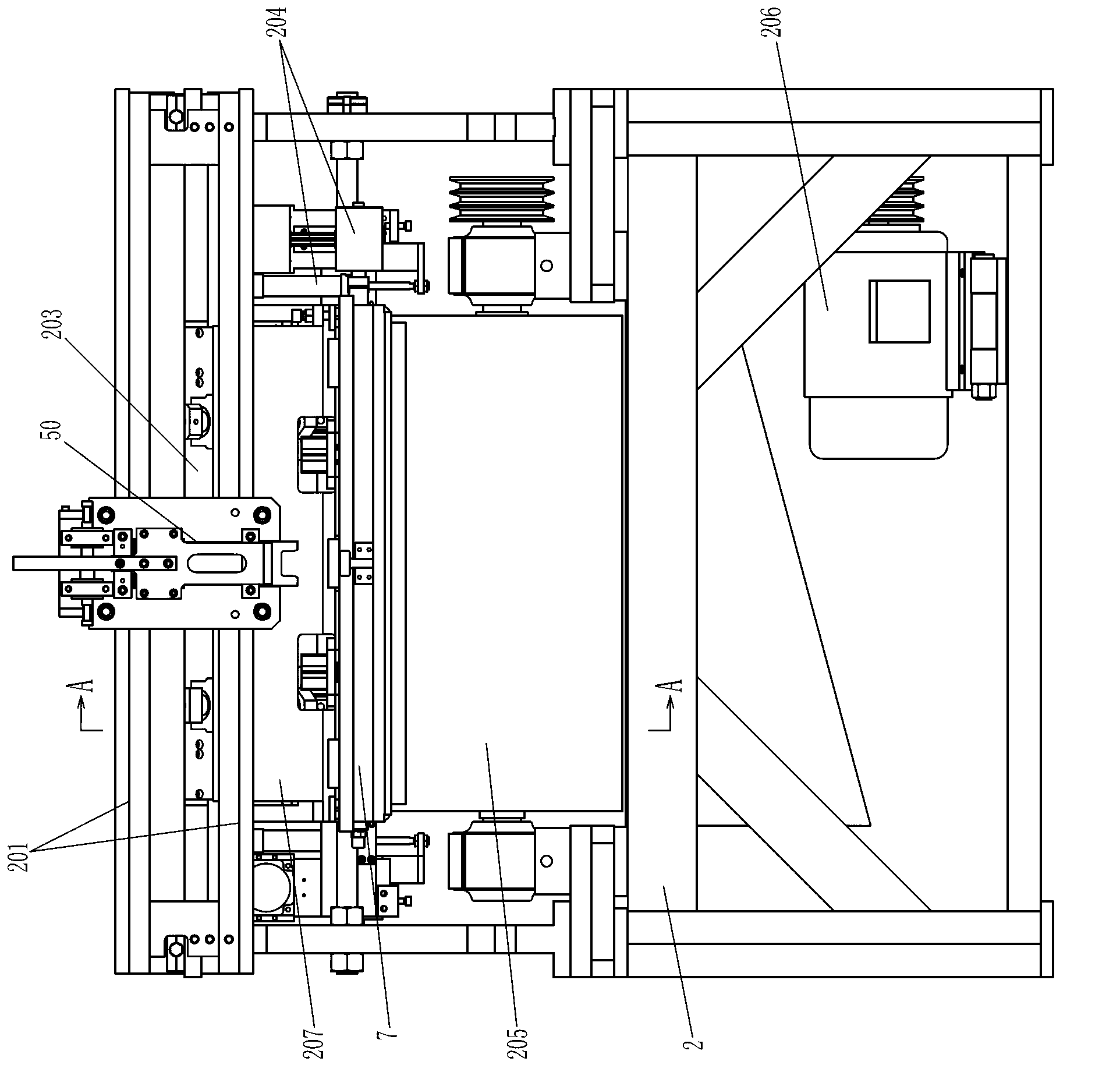

[0040] Such as figure 1 The shown automatic grinding and polishing system for crystal blanks includes a first left and right transfer mechanism 5 and a second left and right transfer mechanism 6 arranged in parallel front and back, along with the first left and right transfer mechanism 5 arranged in sequence from left to right with loading and unloading workers position (the feeding position 12, the feeding position 13, and the cooling position 14), multiple upper hemisphere grinding and polishing stations (including the upper hemisphere grinding and polishing processing primary grinding station 21, secondary grinding station 22. The first polishing station 23 and the second polishing station 24) and the docking station (wherein the docking position 31 and the cleaning position 32), along the second left and right transfer mechanism 6 are arranged in sequence from right to left with docking stations ( Among them, the docking powder dipping position 33 and the waiting position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com