Underwater butt-joint method for pipelines

An underwater docking and pipeline technology, applied in pipeline laying and maintenance, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve problems such as poor applicability, and achieve high docking efficiency, easy operation, and a wide range of applicable water depths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

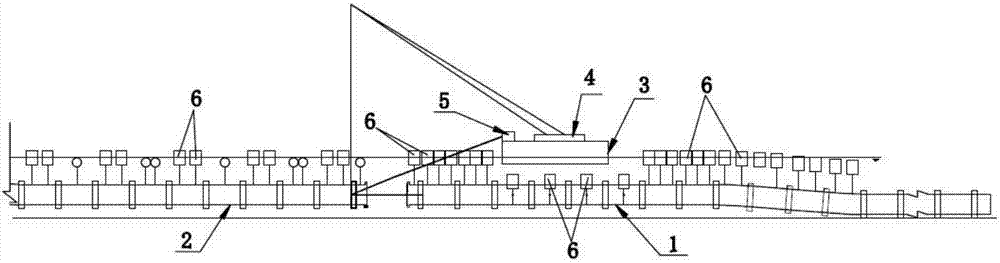

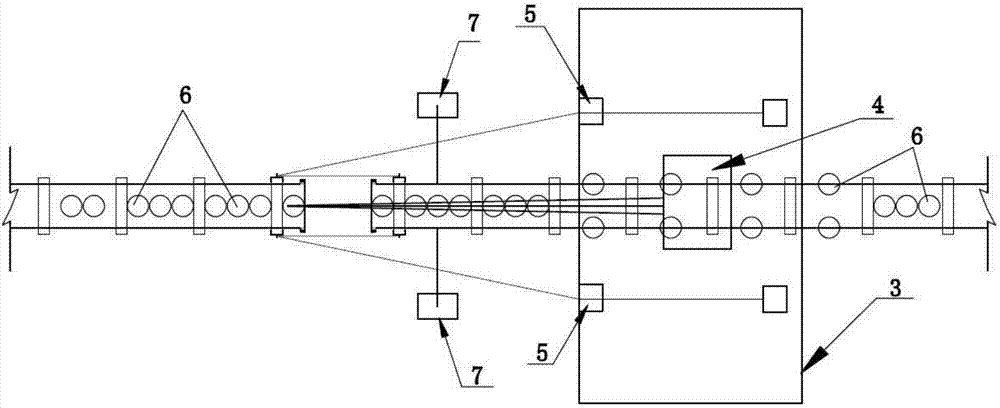

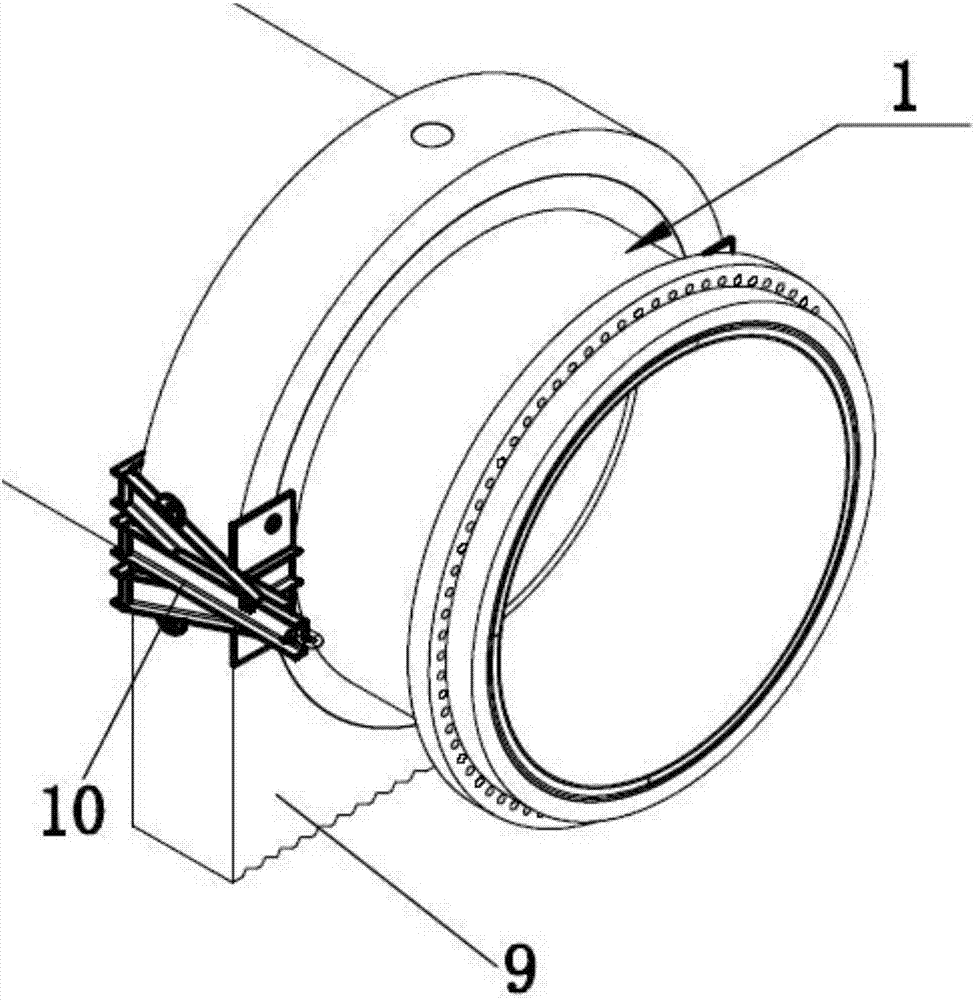

[0027] like Figure 1 to Figure 6 As shown, the present invention discloses a method for underwater docking of pipelines, including an installed pipeline 1, a pipeline to be installed 2 and a barge 3. The barge 3 is provided with a crawler crane 4 and a hoist 5. The docking of the installed pipeline 1 The ends are provided with flanges, and the butt ends of the pipelines 2 to be installed are all provided with flanges, and the following steps are also included: S1: use the air bag 6 to lift the butt end of the installed pipeline 1, and the installed pipeline 1 Install the pulling and closing device 10 and the limiting device 11 at the butt end; S2: Remove the blind plate and sand retaining plate of the butt end of the installed pipeline 1, and perform irrigation and settlement on the installed pipeline 1; S3: The pipeline 2 to be installed is irrigated and settled through The crawler crane 4 makes the pipeline 2 to be installed correspond to the height of the installed pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com