Patents

Literature

36results about How to "Simple docking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

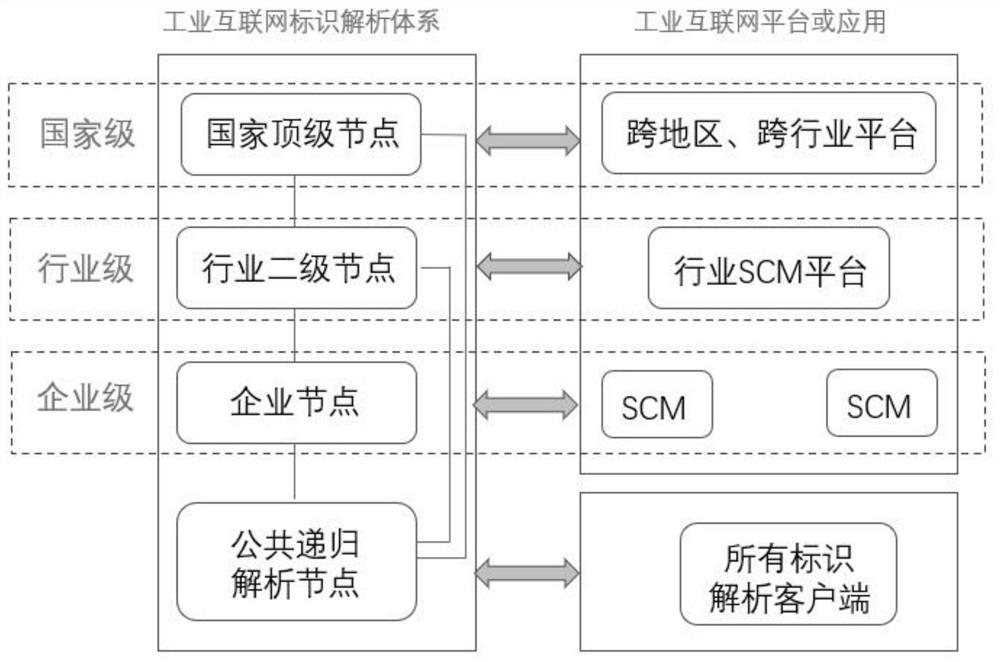

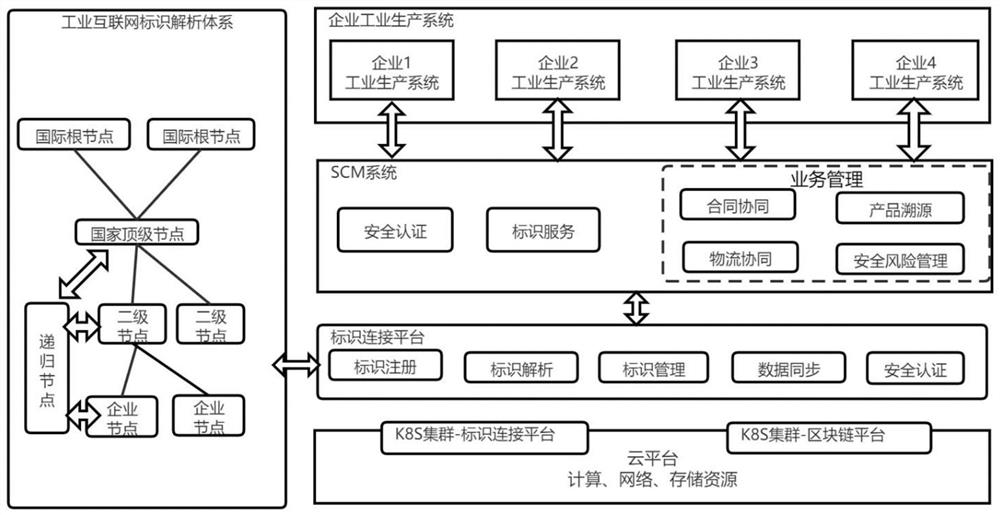

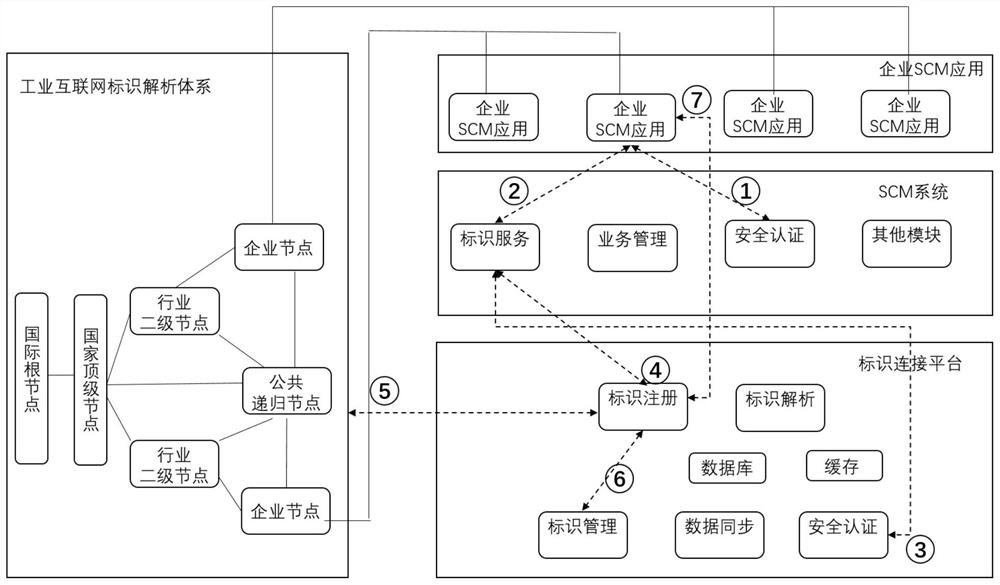

SCM-oriented industrial Internet identifier registration and analysis method and identifier connection platform and system

ActiveCN112491960ABreak the status quo of strong association constructionSimple dockingTransmissionManufacturing computing systemsThe InternetEngineering

The invention discloses an SCM-oriented industrial Internet identifier registration and analysis method and an identifier connection platform and system, and the method comprises the steps: calling aninterface of an industrial Internet identifier analysis system for identifier registration according to a client identifier registration request; storing the identifier mapping relationship of the identifier registration information into an identifier connection platform database, and returning the identifier registration information to the client; according to the client identifier analysis request, performing identifier analysis query in an identifier connection platform cache, an identifier connection platform database or an industrial Internet identifier analysis system, and returning theobtained corresponding identifier mapping relationship to the client. According to the invention, the SCM system is associated with the industrial Internet identifier analysis system through the identifier connection platform, so that the docking mode of the enterprise SCM application and a plurality of secondary nodes is simplified, the current situation that most of SCM applications are strongly associated and constructed with the industrial secondary nodes at present is broken through, and the identifier service docking efficiency is improved.

Owner:COMP NETWORK INFORMATION CENT CHINESE ACADEMY OF SCI

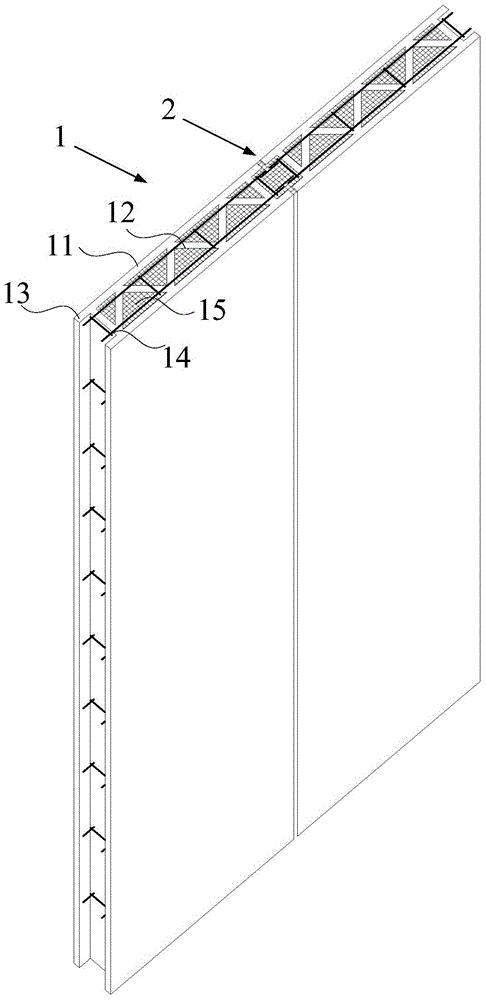

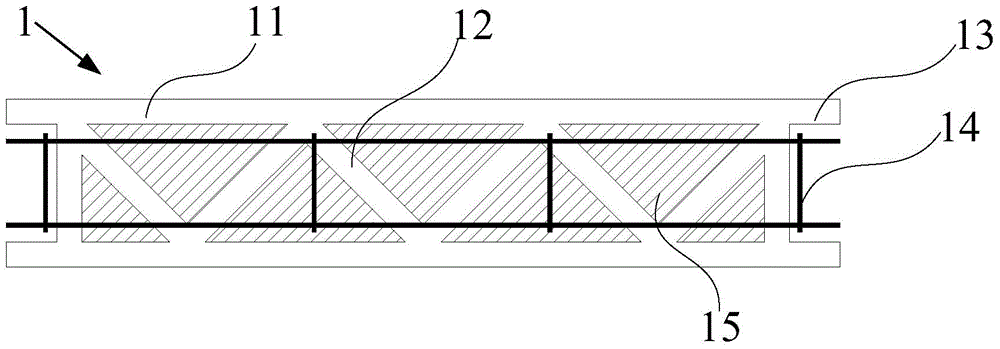

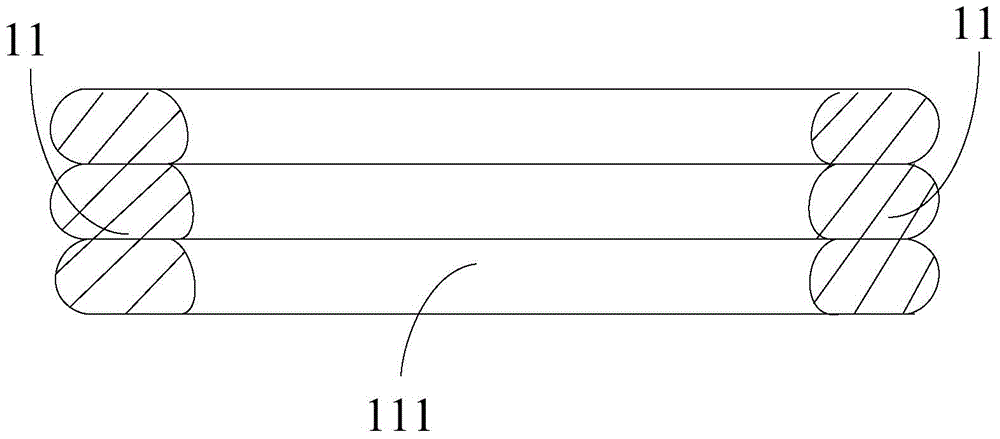

3D printing internal parting wall and construction method of 3D printing internal parting wall

The invention discloses a 3D printing internal parting wall and a construction method of the 3D printing internal parting wall. The 3D printing internal parting wall comprises a plurality of prefabricated internal parting wall units formed according to the 3D printing technology and arranged side by side, first packing materials arranged in the prefabricated internal parting wall units, steel wire gauze sheets arranged in column space and second packing materials arranged in the column space, wherein butt joint grooves are formed in the two ends of each prefabricated internal parting wall unit, and the column space is formed by butt joint of every two adjacent butt joint grooves. A truss system is applied to an internal parting wall system, overall printing molding is achieved through a 3D printing machine, and the building requirements of walls with special-shaped building models are met; meanwhile, the performance of 3D printing materials is sufficiently played, the automatic degree is high, a large amount of manpower and a large number of materials are saved, and building rubbish is not generated. Continuous concave-convex lines are formed on the surfaces of the prefabricated internal parting wall units; the connection strength between the prefabricated internal parting wall units and the packing materials is improved; compared with a smooth surface, the force of friction is improved, and the combination strength is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

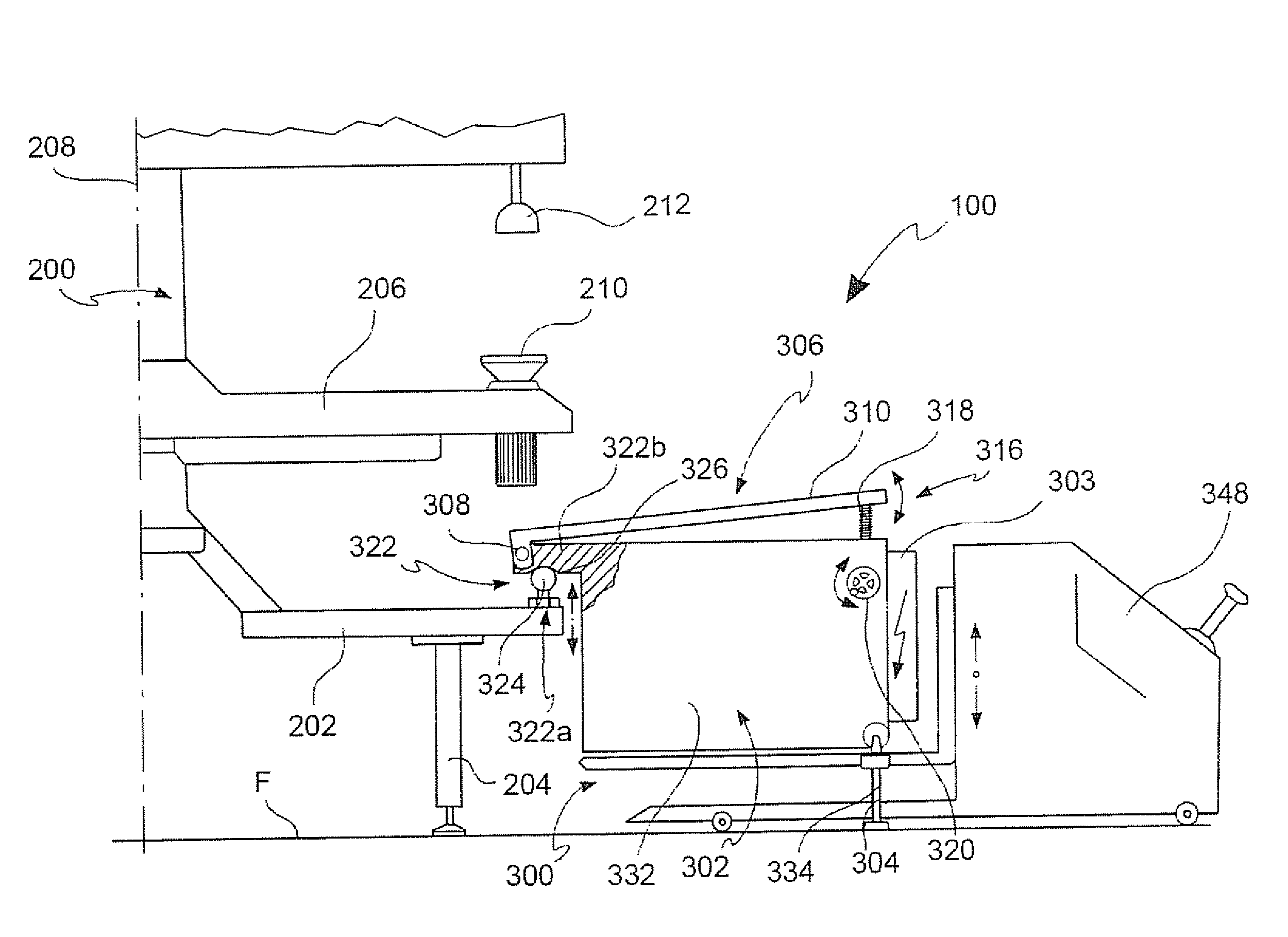

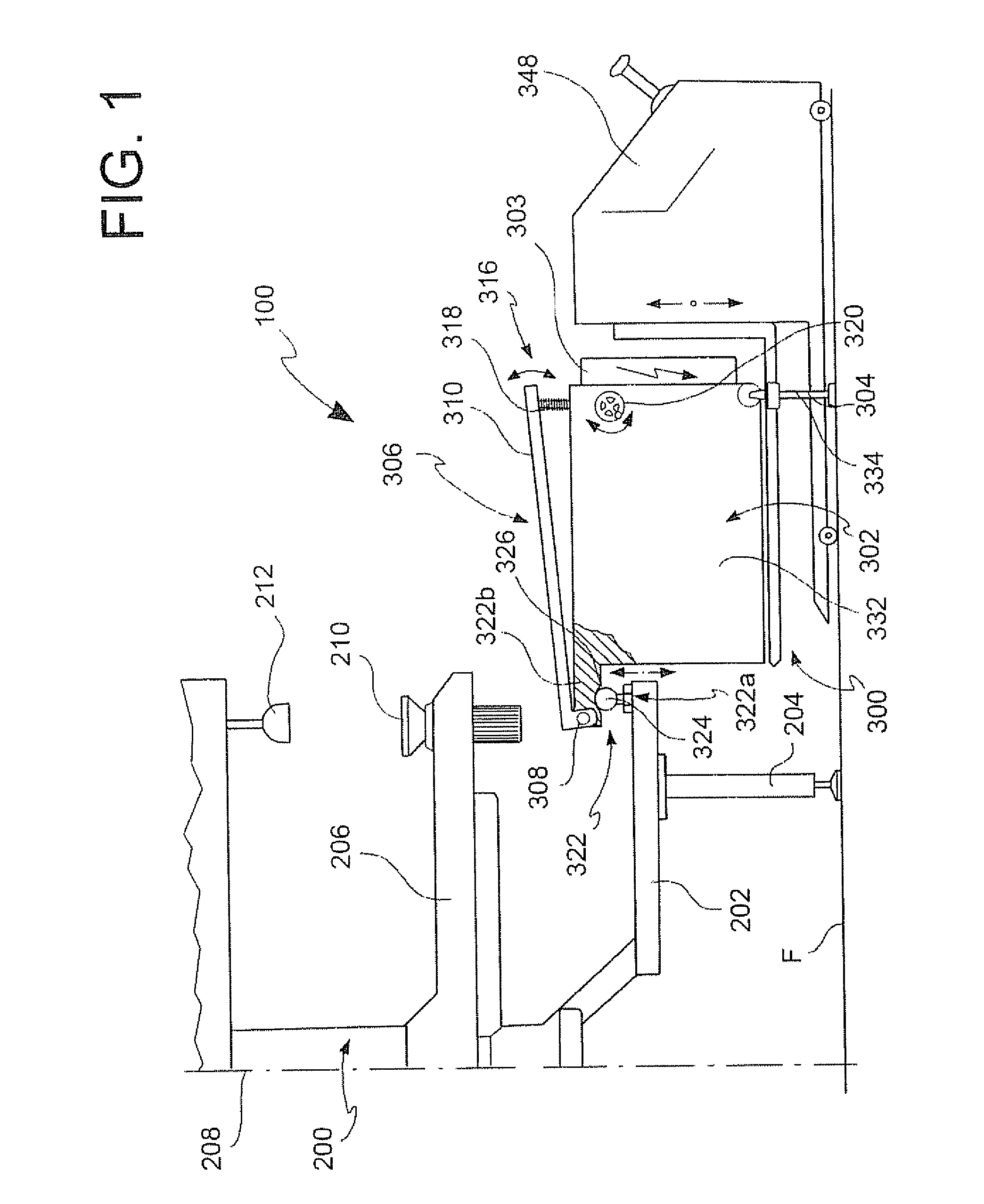

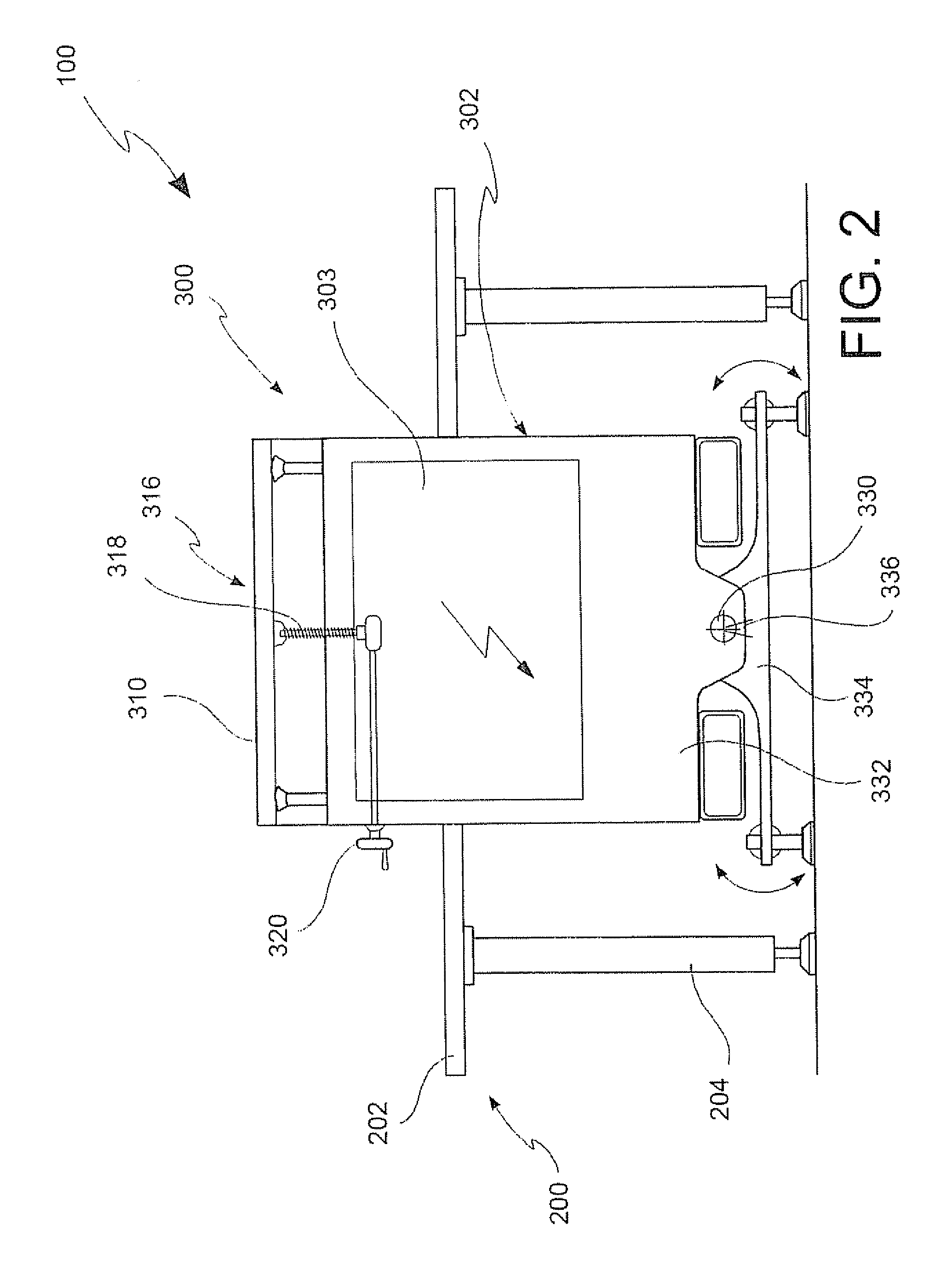

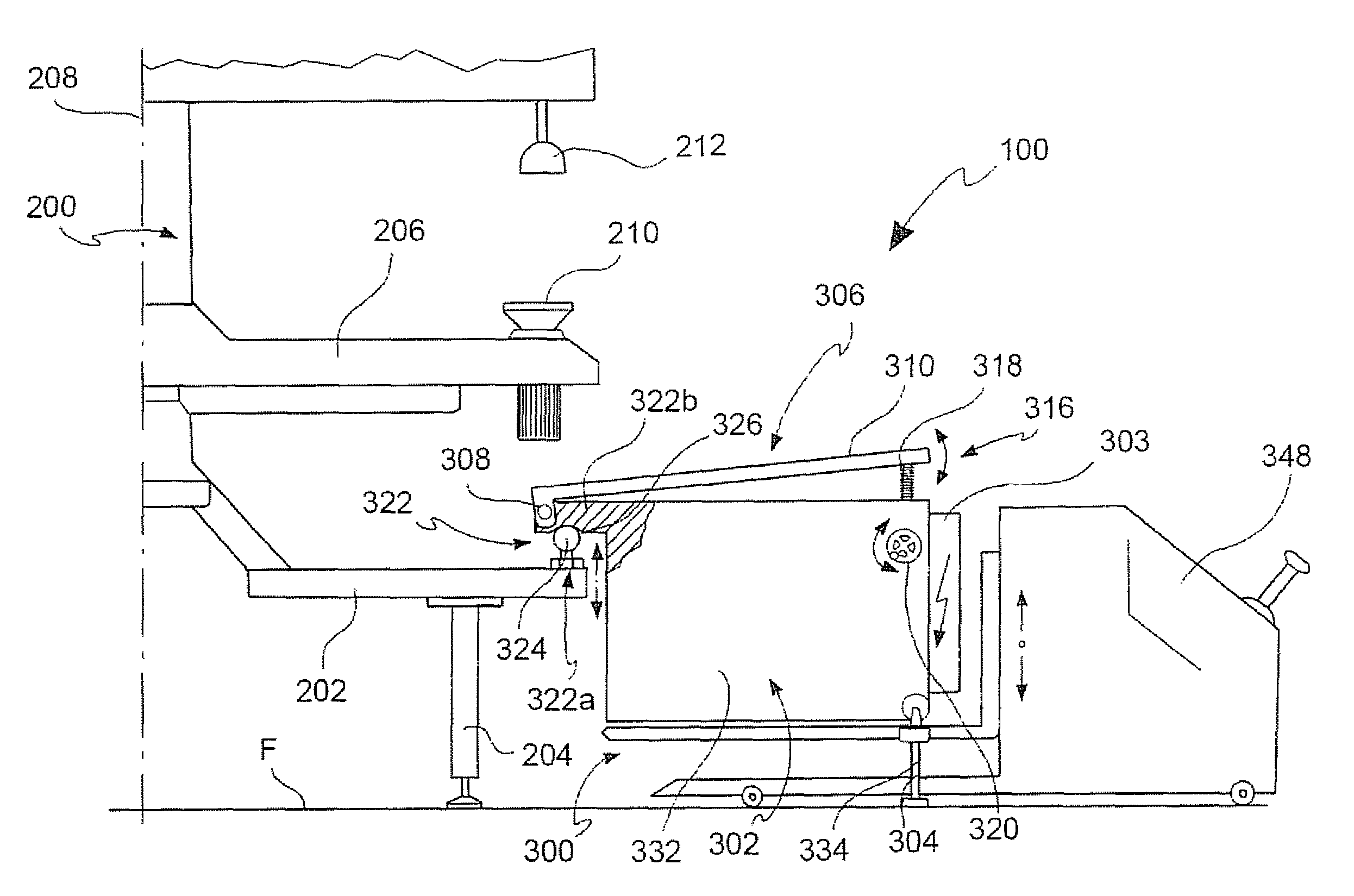

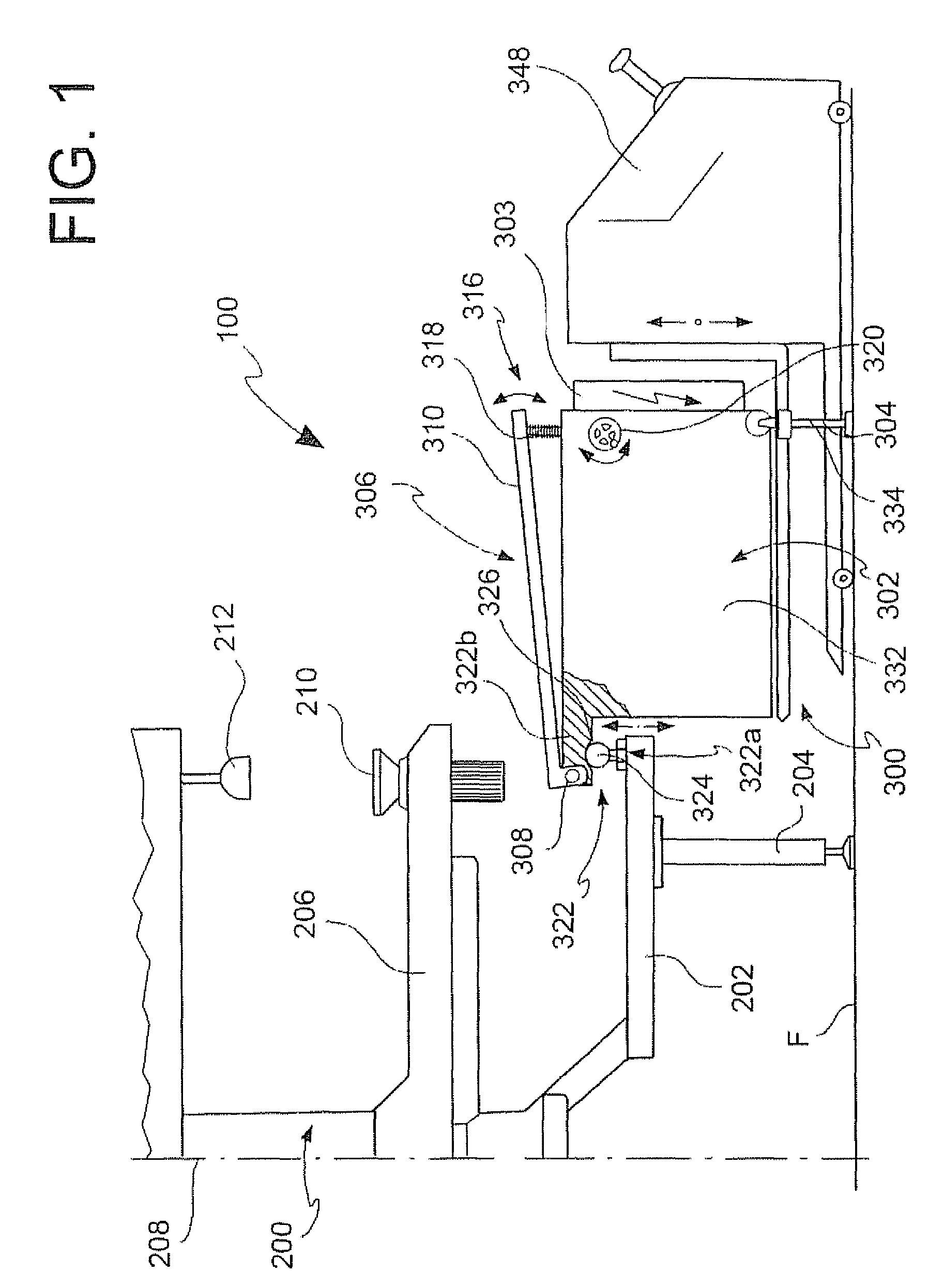

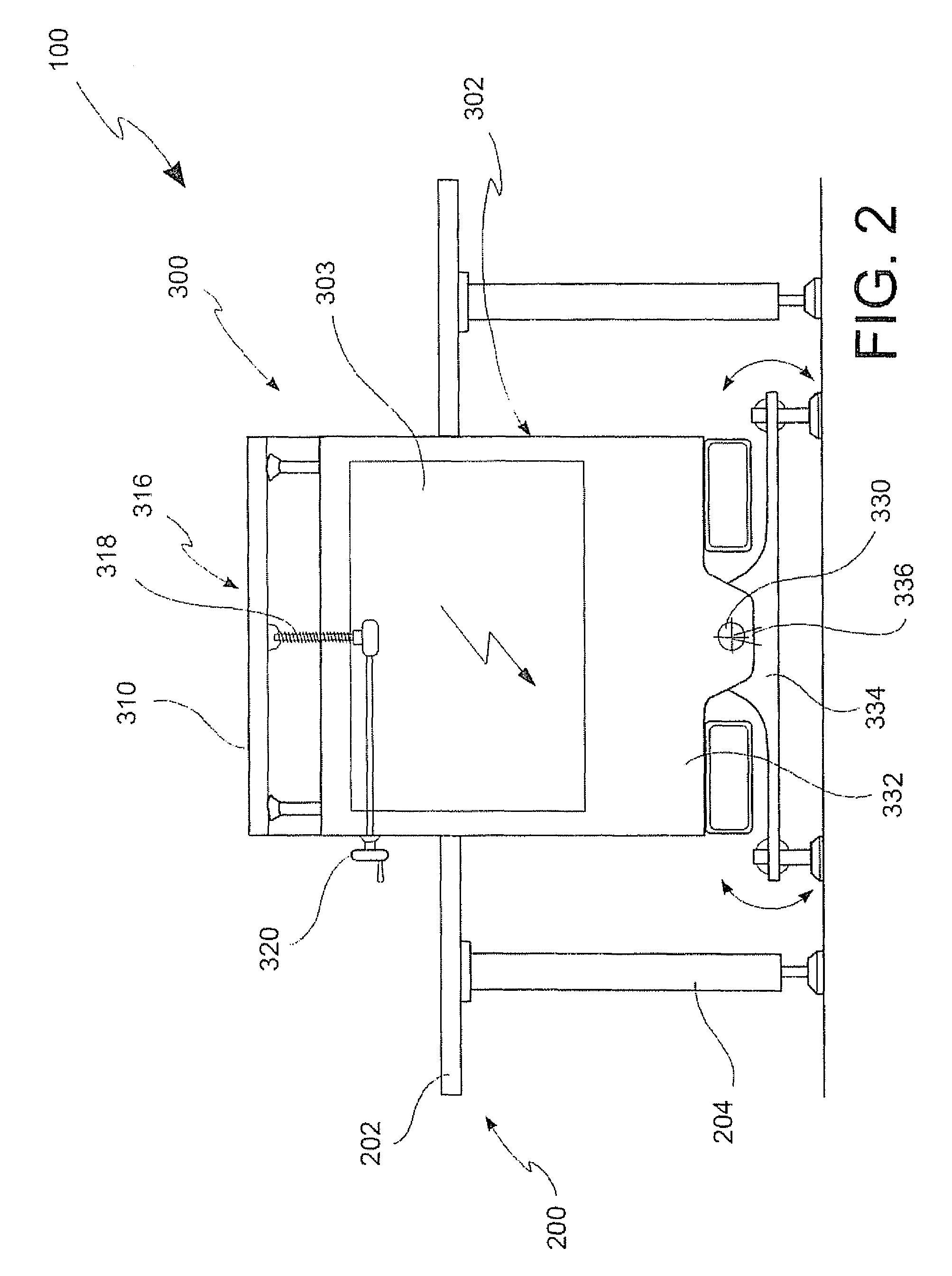

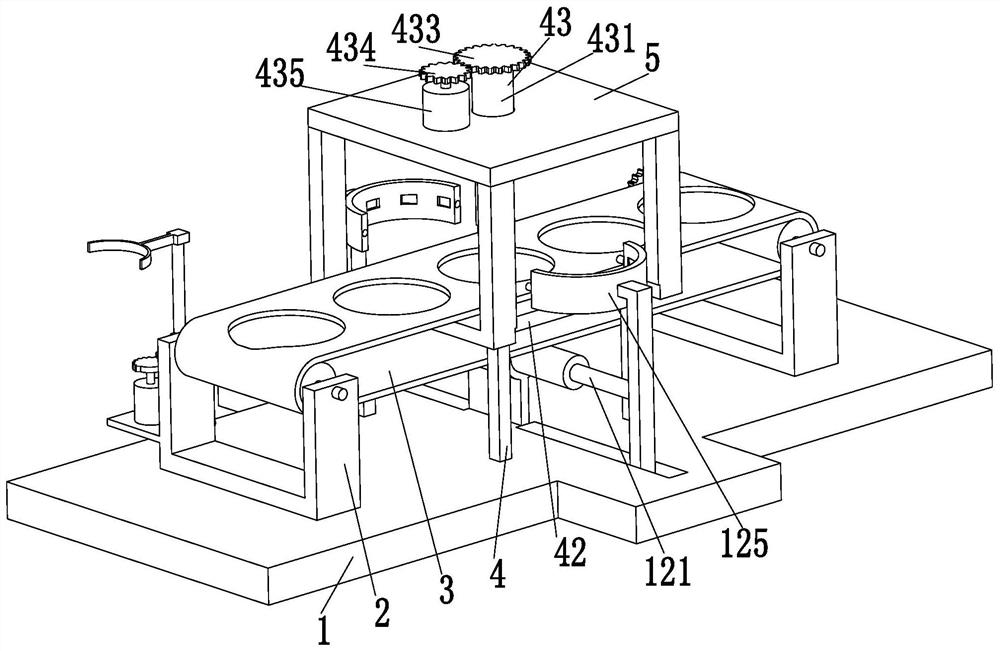

Modular Labeling Station

InactiveUS20090301662A1Simple dockingSimplified levellingMechanical working/deformationLaminationModularityEngineering

Modular labeling station suitable for being detachably connectale to a labeling machine in a labeling arrangement. The labeling station comprises a base suitable to lay on a floor at a side distal from the labeling machine and to lay substantially on the labeling machine at a side proximal to the labeling machine itself, and a labeling unit mounted on the base in an adjustable manner. The base lays on the labeling machine at a portion that is structurally independent from the labeling unit.

Owner:SIDEL HLDG & TECH

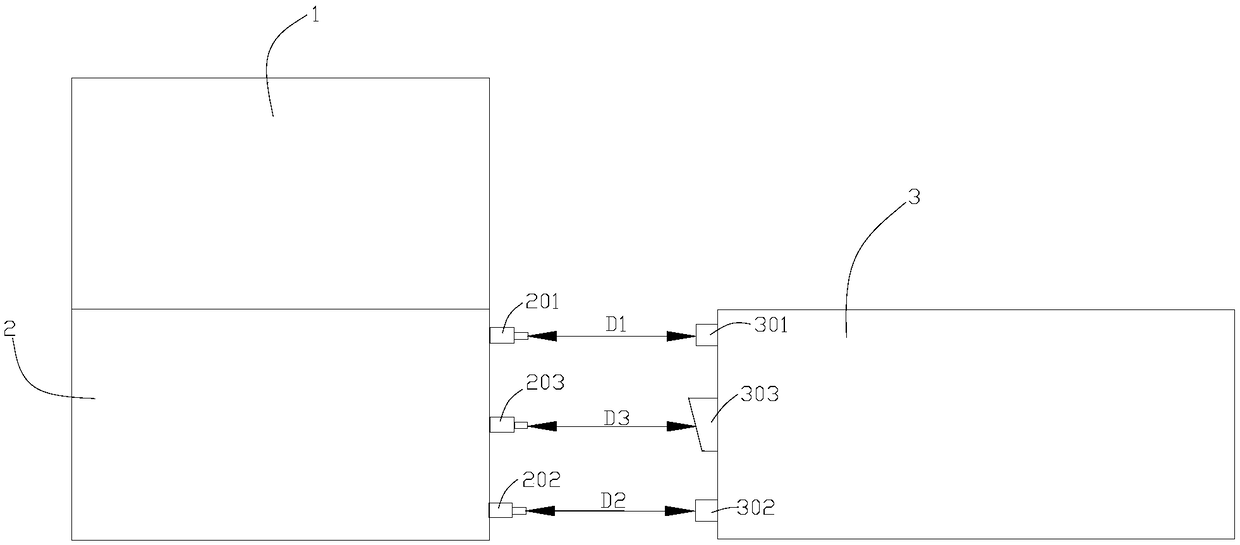

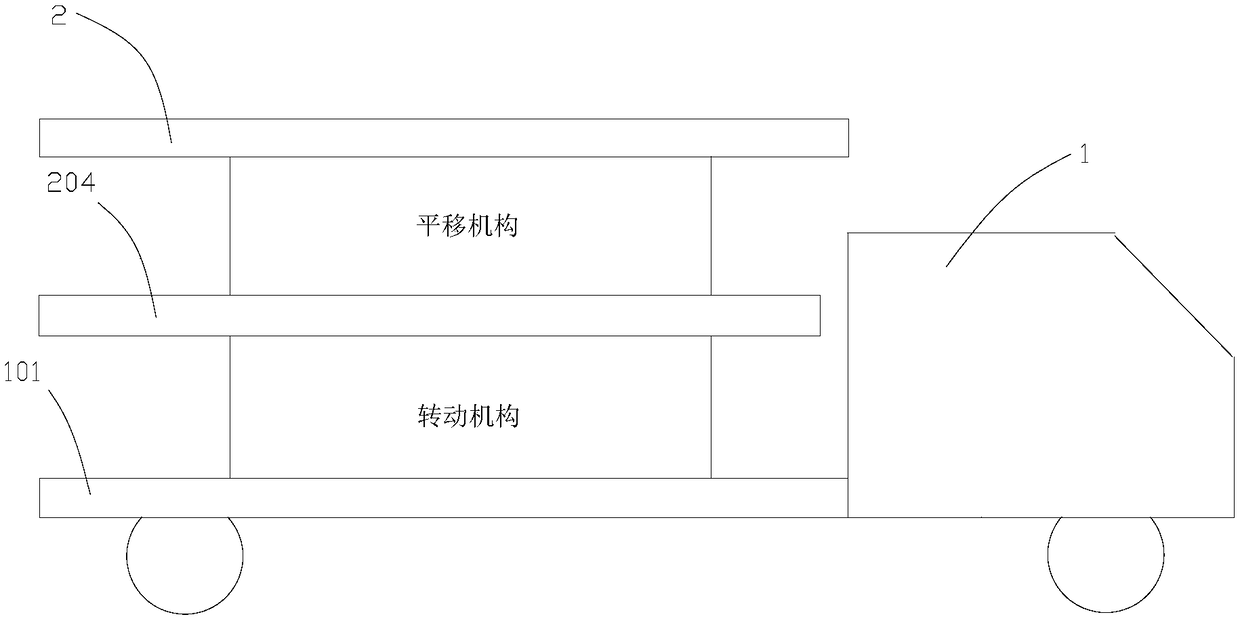

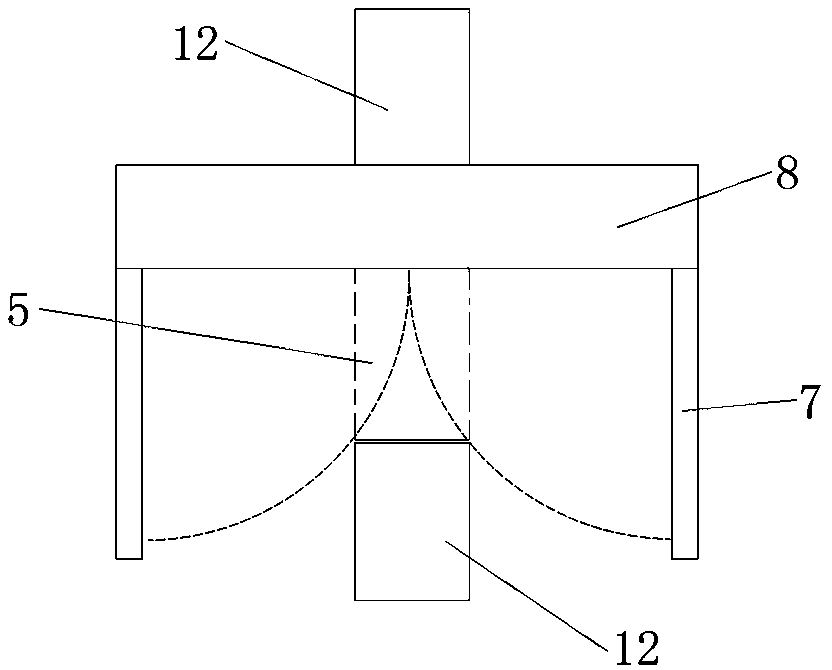

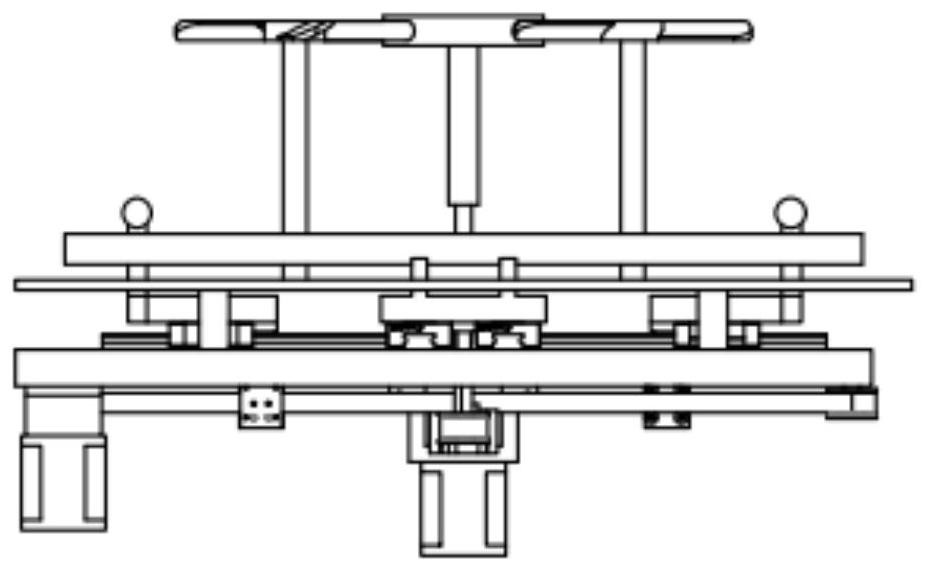

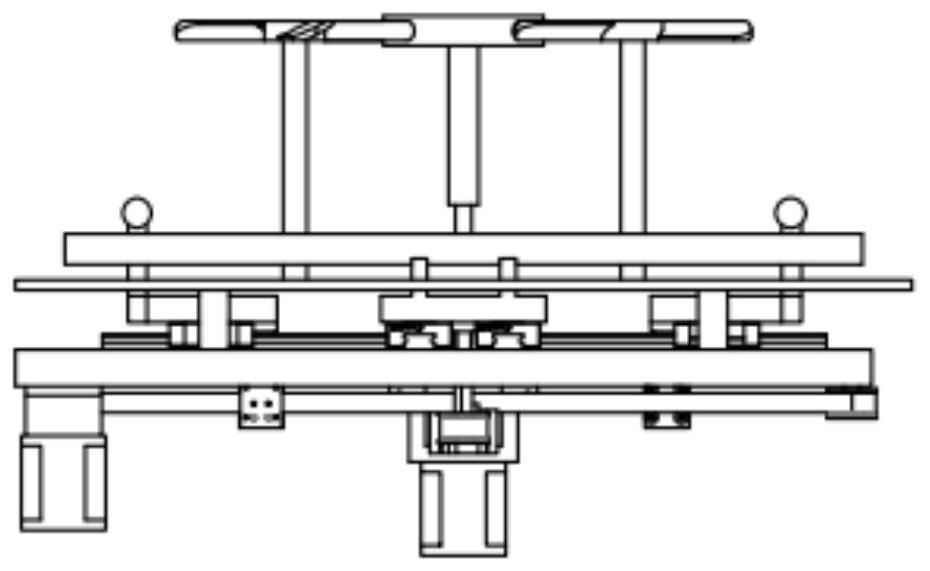

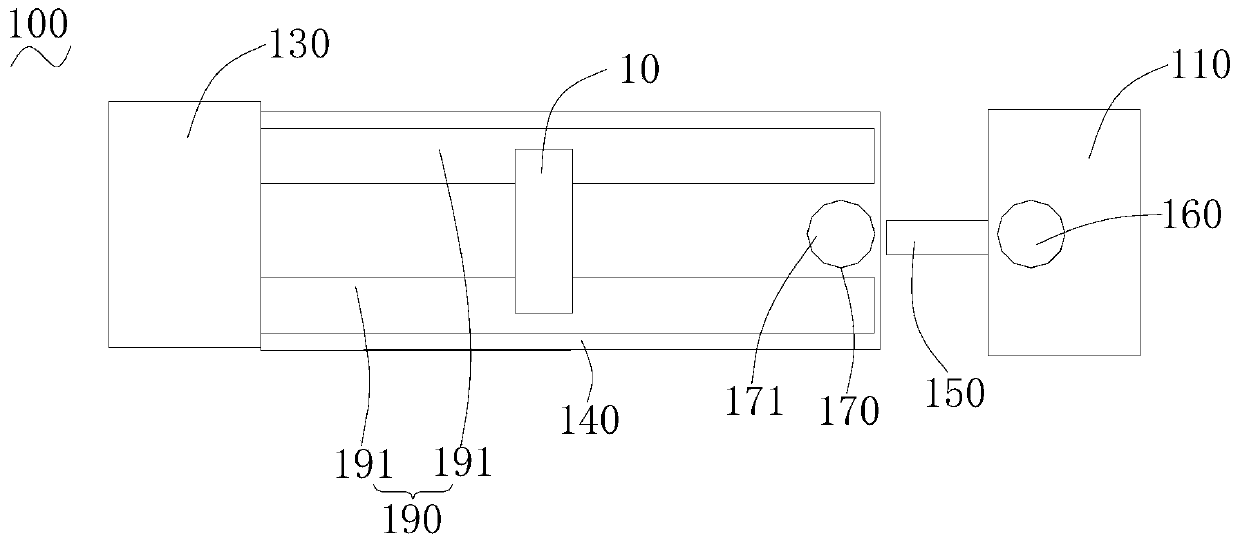

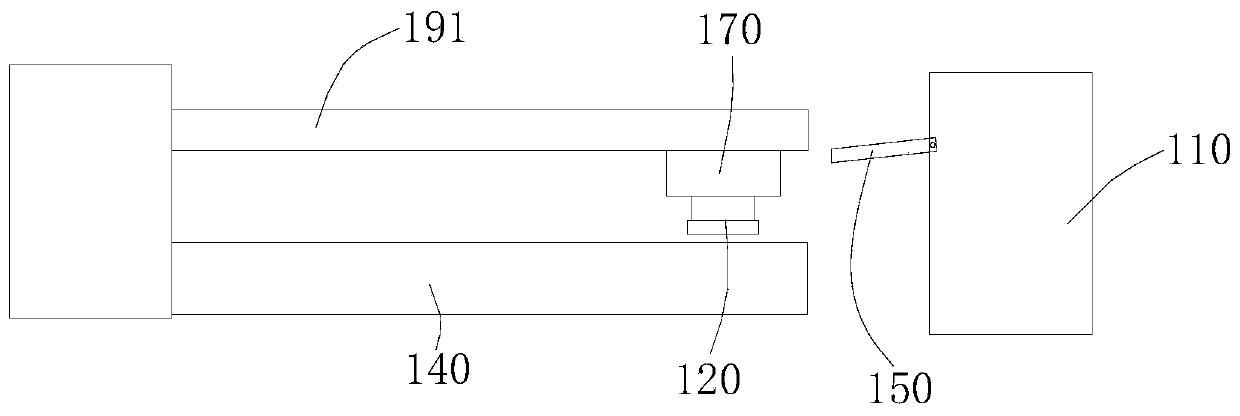

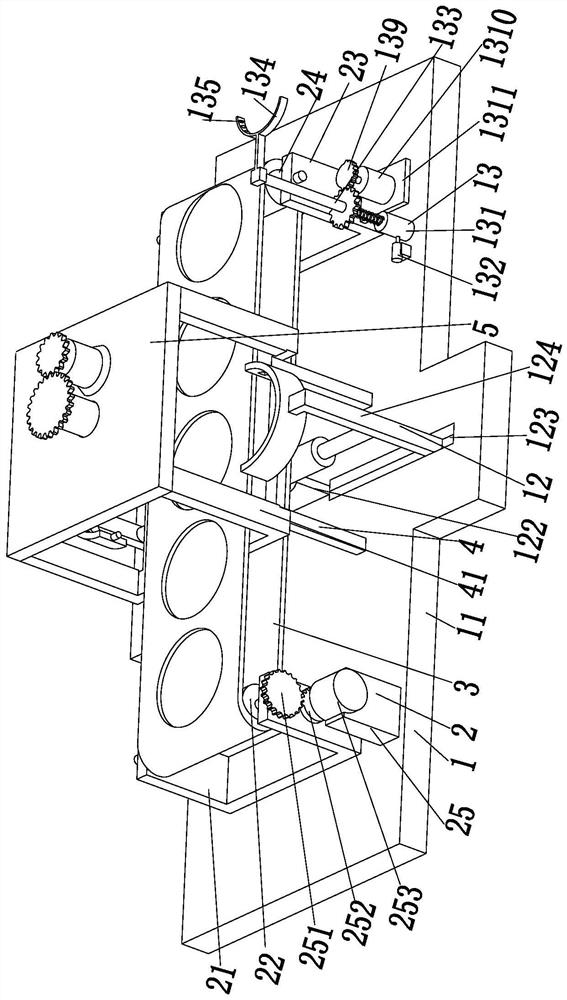

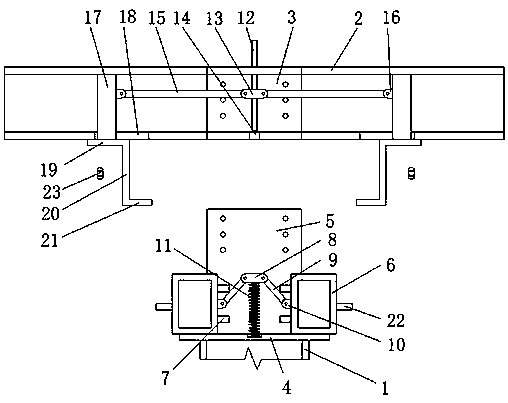

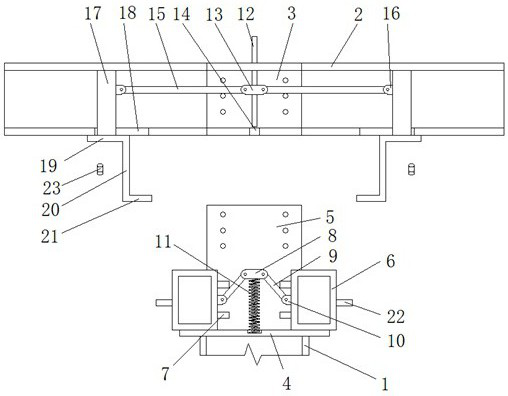

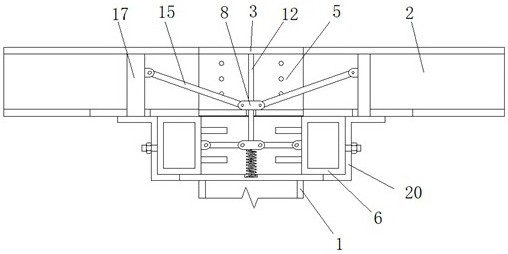

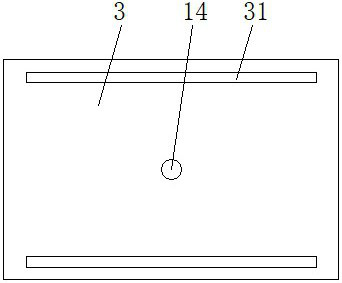

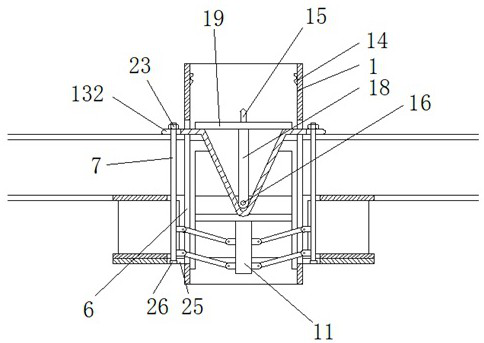

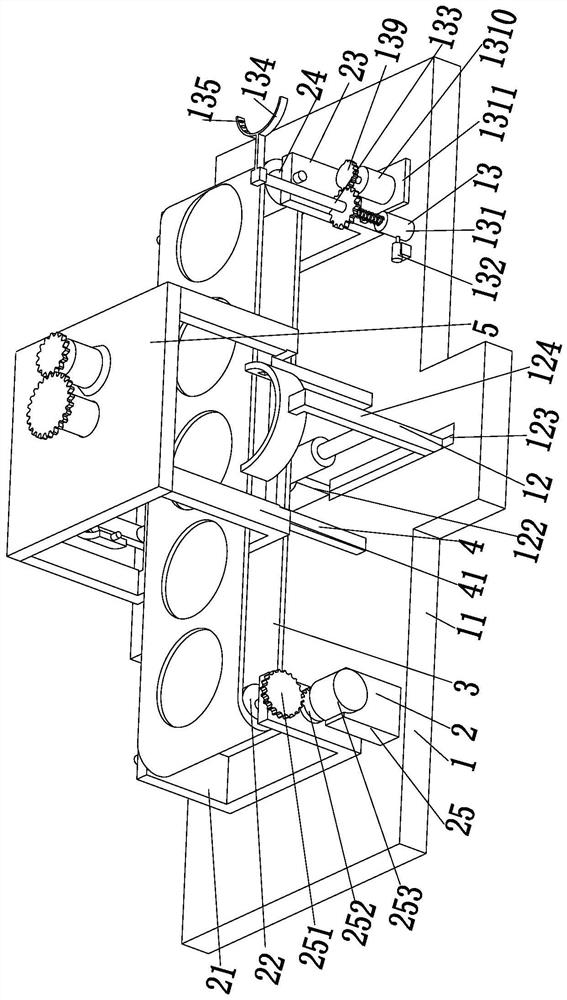

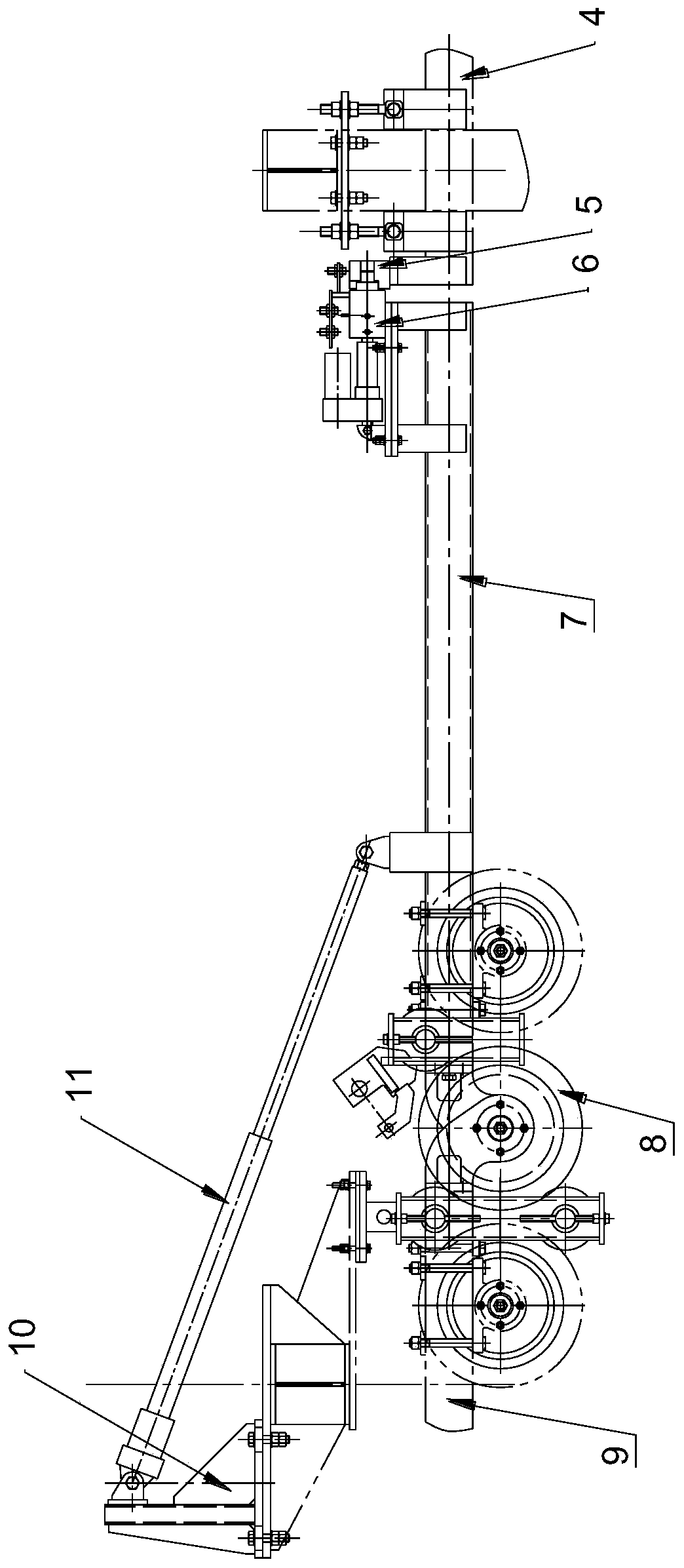

Docking method of automatic guided vehicle (AGV) docking platform

InactiveCN109205208AImprove docking accuracyImprove machining accuracyMechanical conveyorsElectricityProximity sensor

Disclosed is a docking method of an automatic guided vehicle (AGV) docking platform. A control terminal, a rotating mechanism, a horizontal moving mechanism, a load-bearing table, a first proximity sensor, a second proximity sensor and a third proximity sensor are included. The rotating mechanism and the horizontal moving mechanism are arranged on a vehicle body of the AGV. The rotating mechanismis used for adjusting the rotation angle of the load-bearing table. The horizontal moving mechanism is used for enabling the load-bearing table to move forward or backward. The first proximity sensorand the second proximity sensor are arranged at the two ends of the side wall of the load-bearing table and electrically connected with the control terminal. The third proximity sensor is arranged inthe middle of the side wall of the load-bearing table and electrically connected with the control terminal. Compared with the prior art, as for the docking method of the AGV docking platform, the parallelism of the load-bearing table is adjusted by comparing a distance value D1 and a distance value D2, and the position of the load-bearing table is adjusted by comparing a distance value D3 and a distance value D3', so that the docking precision of AGV equipment is improved; and when the positioning precision is adjusted, the vehicle body of the AGV does not need to be adjusted overall, and thedocking method has the advantages of simple docking mode, high positioning precision and easy realization.

Owner:GUANGDONG JATEN ROBOT & AUTOMATION

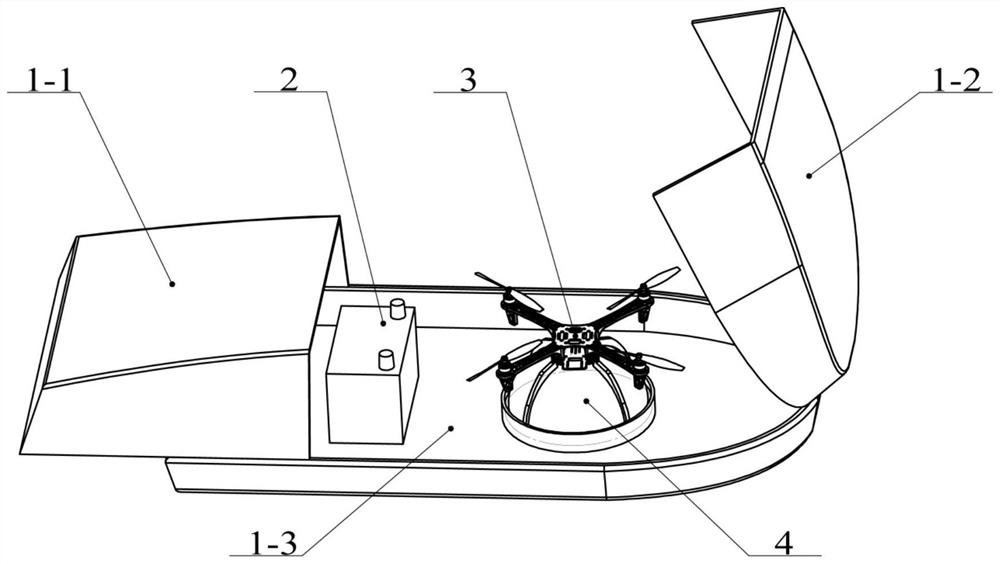

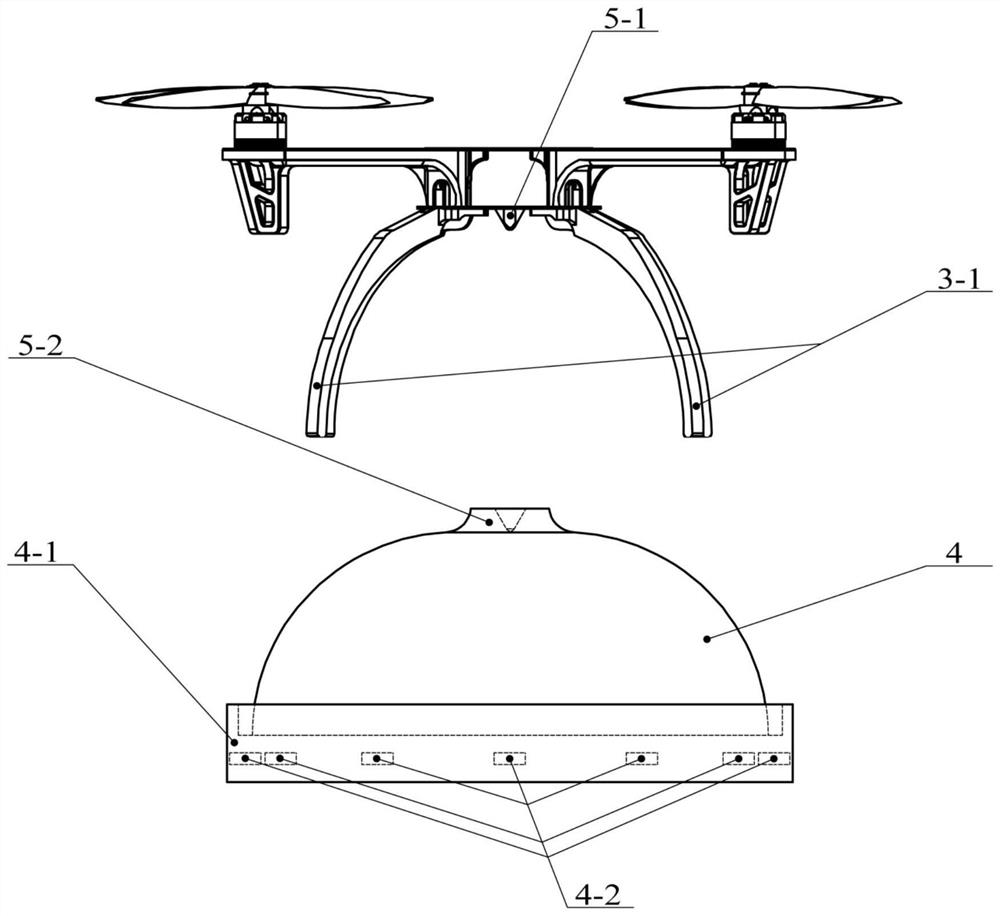

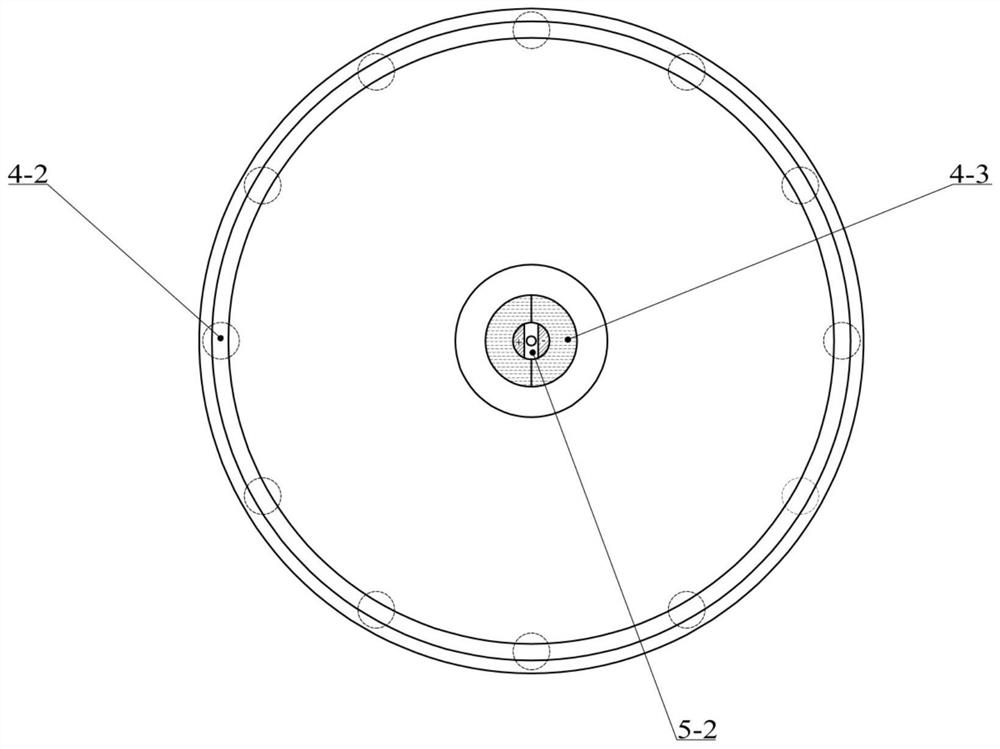

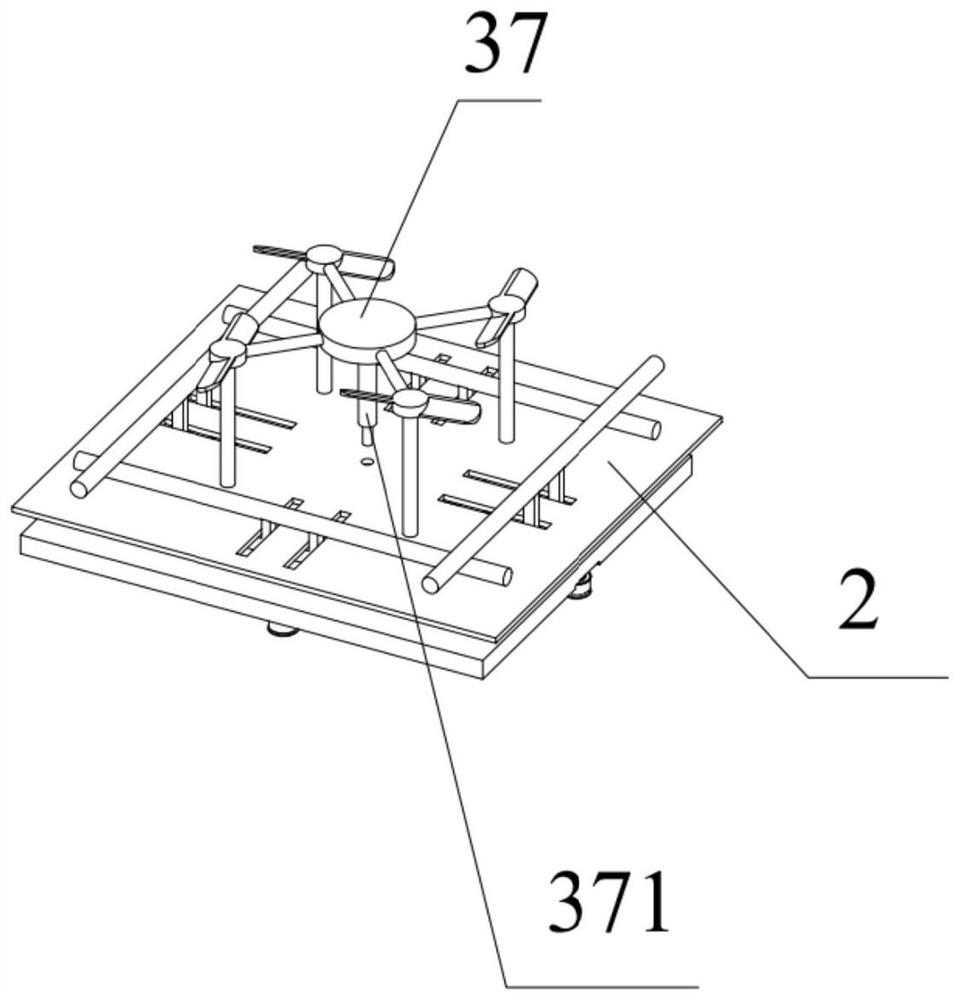

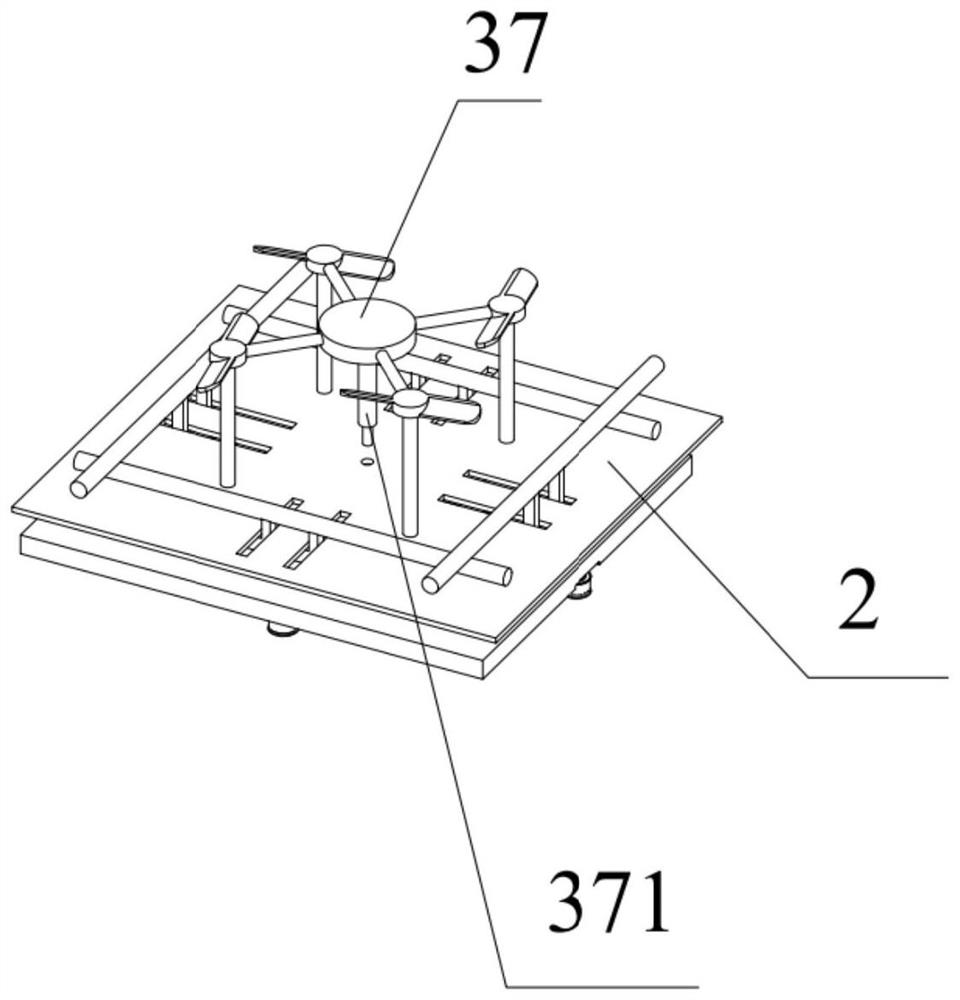

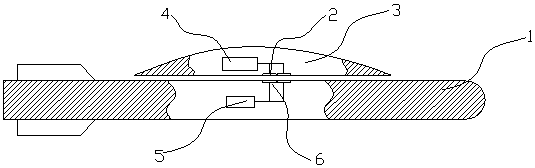

Vehicle-mounted autonomous charging platform for unmanned aerial vehicle

ActiveCN113602516AHas a modular featureImprove general performanceCharging stationsElectric vehicle charging technologyUncrewed vehicleControl theory

The invention discloses a vehicle-mounted autonomous charging platform for an unmanned aerial vehicle, belonging to the technical field of unmanned aerial vehicles. The vehicle-mounted autonomous charging platform comprises a roof hangar, a take-off and landing boss and a quad-rotor unmanned aerial vehicle which are mounted in the roof hangar, and a charging interface device matched with the unmanned aerial vehicle and the take-off and landing boss, wherein an electromagnet array is arranged at the bottom of the take-off and landing boss and used for tightly adsorbing landing legs of the unmanned aerial vehicle; and the unmanned aerial vehicle comprises a controller, the controller is divided into a position controller and an attitude controller, and position stabilization and attitude stabilization of the unmanned aerial vehicle are respectively controlled by calculating resultant external force and resultant external torque generated by the unmanned aerial vehicle. The autonomous charging platform is further provided with a circuit system; when the unmanned aerial vehicle is charged, the controller measures voltage every 0.1 s, on-off information of a charging circuit is indirectly obtained, and if the charging circuit is disconnected, the controller controls the unmanned aerial vehicle to adjust posture again until the charging circuit is closed again to continue charging. According to the invention, a requirement on the pose accuracy of the unmanned aerial vehicle is reduced, and the robustness and success rate of autonomous landing are improved.

Owner:BEIHANG UNIV

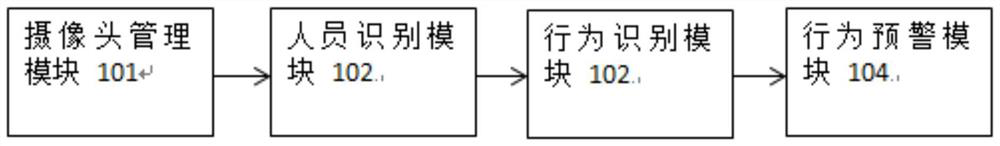

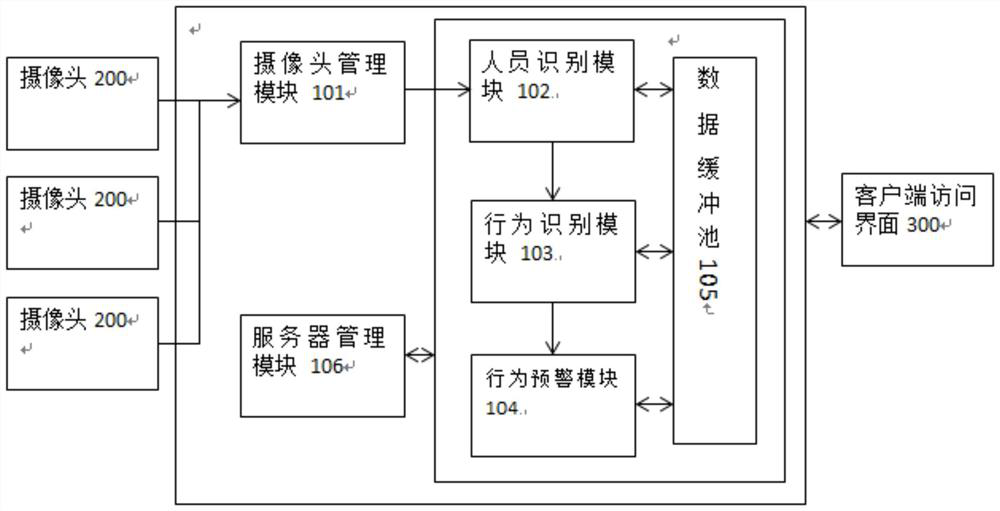

On-duty personnel behavior identification method and system

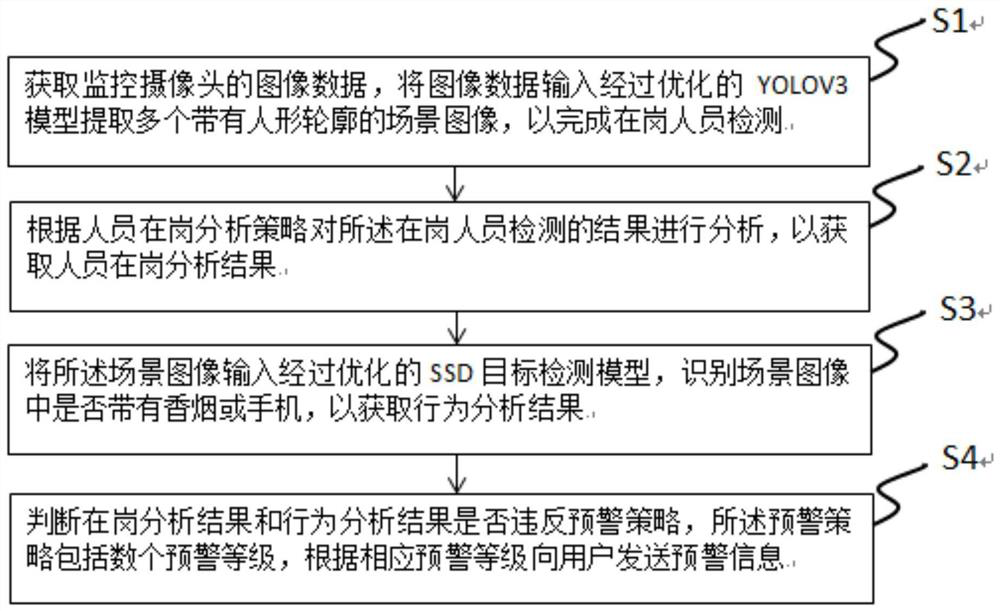

PendingCN113269039AMany types of supportSimple dockingCharacter and pattern recognitionMachine learningPersonnel supervisionImaging data

The invention provides an on-duty personnel behavior identification method and system, which utilizes an artificial intelligence algorithm and a big data analysis technology to improve the on-duty personnel supervision efficiency, and solves the problems of large workload, long time consumption and small coverage of manual inspection. The identification method comprises the following steps: acquiring image data, and inputting the image data into an optimized YOLOV3 model to extract a plurality of scene images with human-shaped contours so as to complete personnel detection; analyzing the detection result of the on-duty personnel to obtain the on-duty condition of the personnel; inputting the scene image into an SSD target detection model, and identifying whether a cigarette or a mobile phone is carried in the scene image; judging whether the behavior of the on-duty person violates an early warning strategy, the early warning strategy comprising a plurality of early warning levels, and sending early warning information to the user according to the corresponding early warning levels.

Owner:南京鸣赫信息技术有限公司

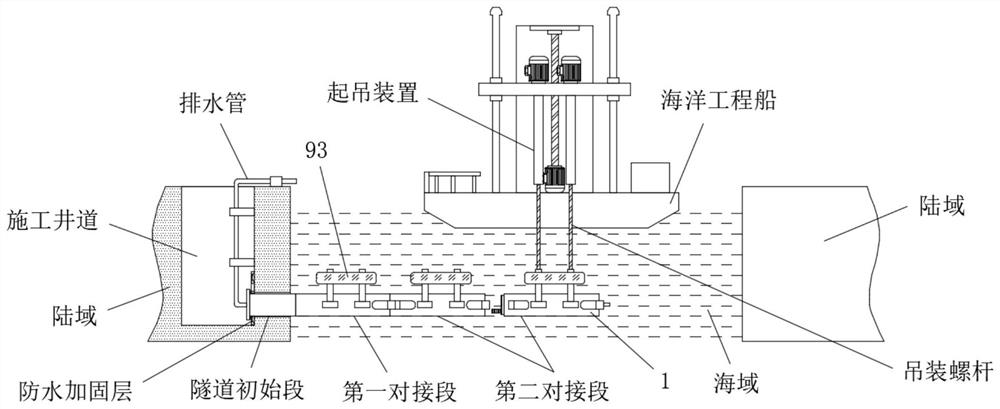

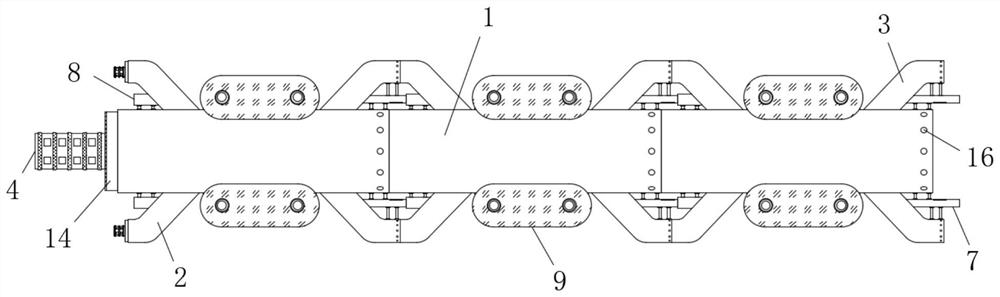

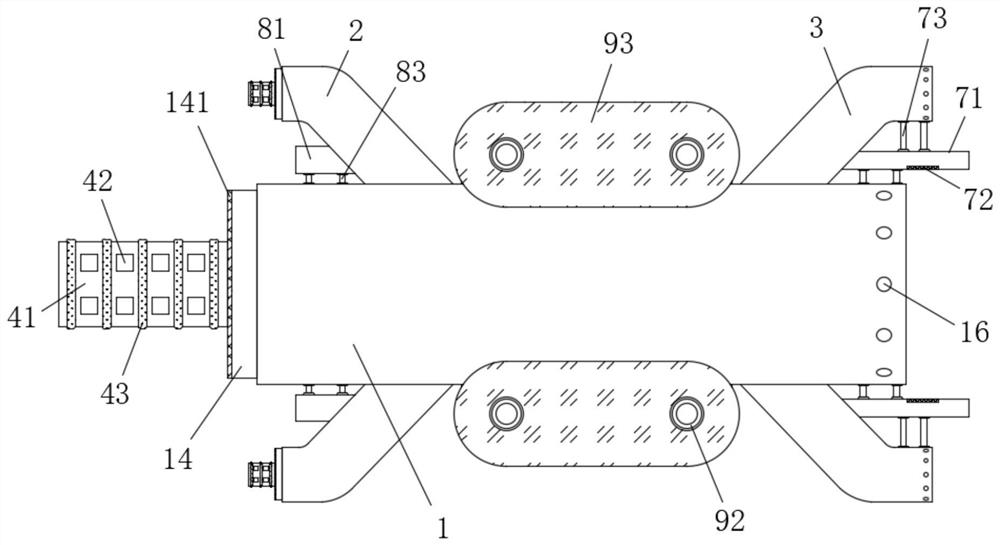

Seabed submerged floating tunnel structure and construction method thereof

InactiveCN113216262APlay the effect of positioning dockingPlay a sealing effectArtificial islandsUnderwater structuresStructural engineeringSeabed

The invention relates to a seabed submerged floating tunnel structure, and belongs to the technical field of tunnels. The seabed submerged floating tunnel structure comprises a tunnel body, the tunnel body comprises a tunnel main body section, two first tunnel branch sections and two second tunnel branch sections, wherein the two first tunnel branch sections and the two second tunnel branch sections are symmetrically arranged on the two sides of the tunnel main body section correspondingly; the two first tunnel branch sections and the two second tunnel branch sections communicate with the interior of the tunnel main body section; and a bearing mechanism located right below a portal is arranged at one end of the tunnel main body section. The invention further discloses a construction method. The seabed submerged floating tunnel structure and the construction method thereof have the advantages that the structure design is reasonable, in addition, the butt joint mode is simple and effective, tunnel butt joint is realized in a pouring connection mode, the stability of tunnel butt joint is improved, the functions of seabed observation and sealing performance test are added in the construction process, in this way, seabed construction is easy to operate, the accuracy and efficiency of tunnel butt joint are improved, in addition, a very safe construction environment is provided, meanwhile, an escape emergency channel is designed in a whole tunnel, and the overall safety performance of the tunnel is improved.

Owner:温州凯胜瑞恒科技有限公司

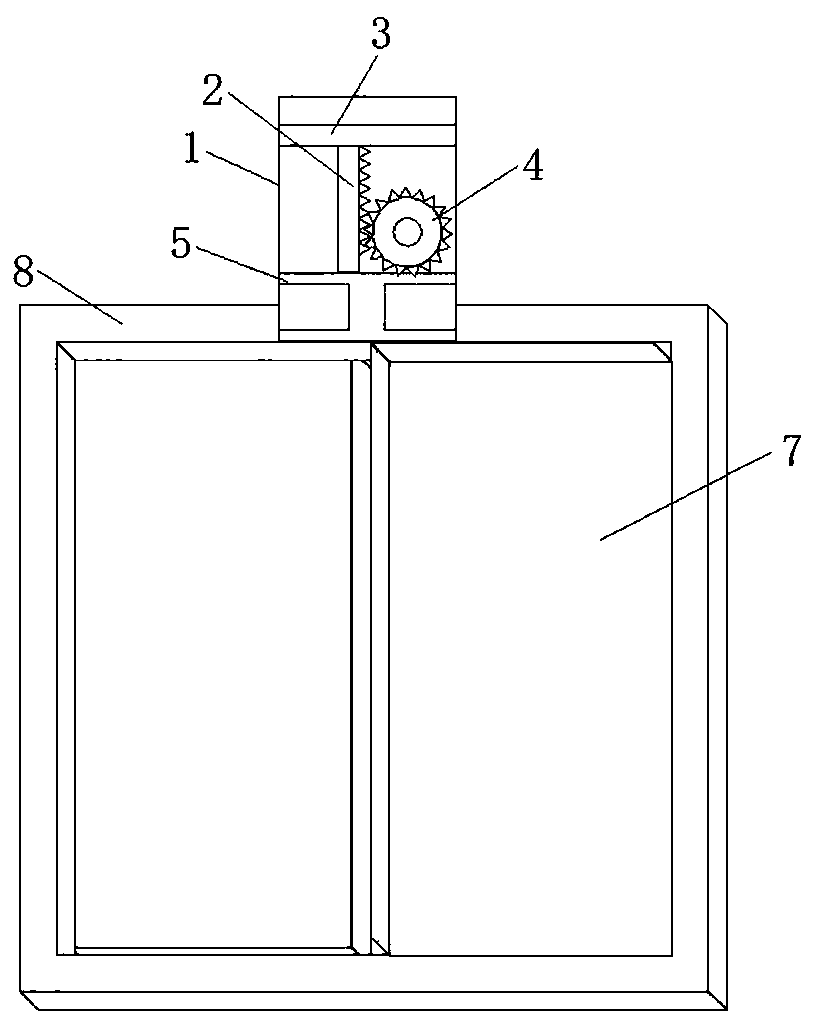

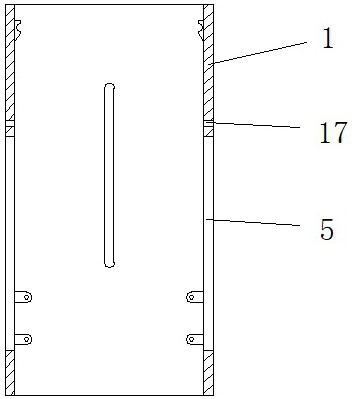

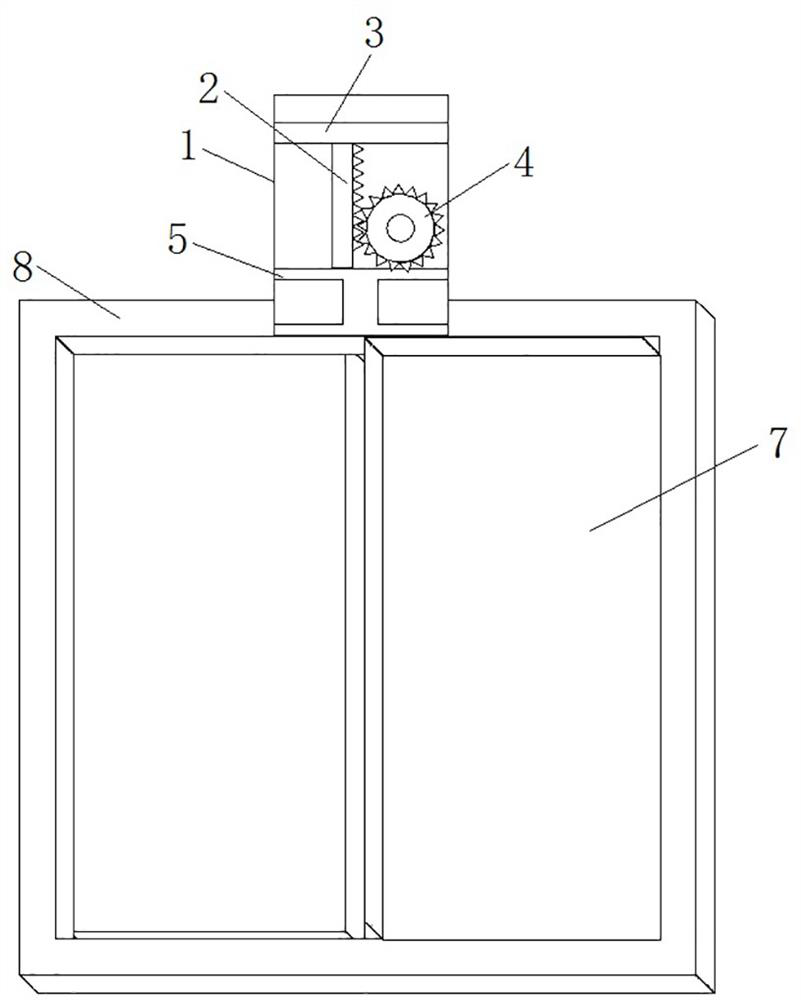

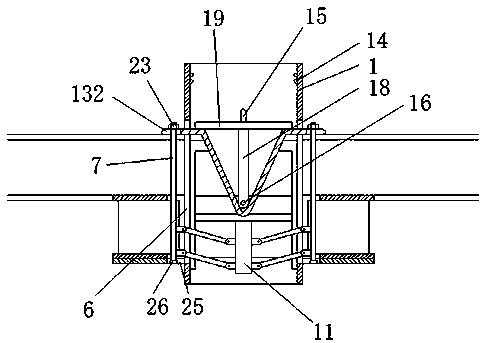

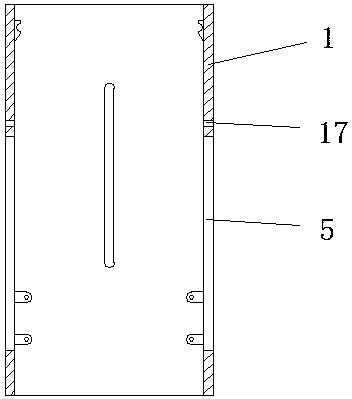

Fireproof door system

ActiveCN110778256ASimple moving trackImprove docking accuracyFireproof doorsPower-operated mechanismFire doorLinear drive

The invention relates to a fireproof door system. The fireproof door system comprises a door frame, a butting rail, an accommodating groove and a linear driving mechanism, wherein a fireproof door ismovably mounted in a door hole of the door frame; the butting rail is controlled to move to the door hole after the fireproof door is opened so as to be in butt joint with a fixing rail, and is controlled to move away from the door hole before the fireproof door is closed; the accommodating groove corresponds to the door hole in the extending direction perpendicular to the fixing rail and is arranged outside the door hole, wherein the accommodating groove can accommodate the butting rail and is arranged on the inner side surface of the door frame or penetrates through the door frame, and the accommodating groove is provided with a groove opening facing the door hole in the extending direction perpendicular to the fixing rail; and the linear driving mechanism is arranged in the accommodating groove and provided with a linear output end connected with the butting rail, and the linear driving mechanism can drive the butting rail to move to the door hole through the groove opening and to be removed from the door hole so as to be placed into the accommodating groove. Compared with the prior art, the fireproof door system has the advantages that the butting accuracy is improved, and it can be ensured that the butting rail is in butt joint with the fixing rail.

Owner:XJ ELECTRIC +2

Modular labeling station

InactiveUS8267142B2Simple dockingSimplified levellingMechanical working/deformationLaminationModularityEngineering

Modular labeling station suitable for being detachably connectable to a labeling machine in a labeling arrangement. The labeling station comprises a base suitable to lay on a floor at a side distal from the labeling machine and to lay substantially on the labeling machine at a side proximal to the labeling machine itself, and a labeling unit mounted on the base in an adjustable manner. The base lays on the labeling machine at a portion that is structurally independent from the labeling unit.

Owner:SIDEL HLDG & TECH

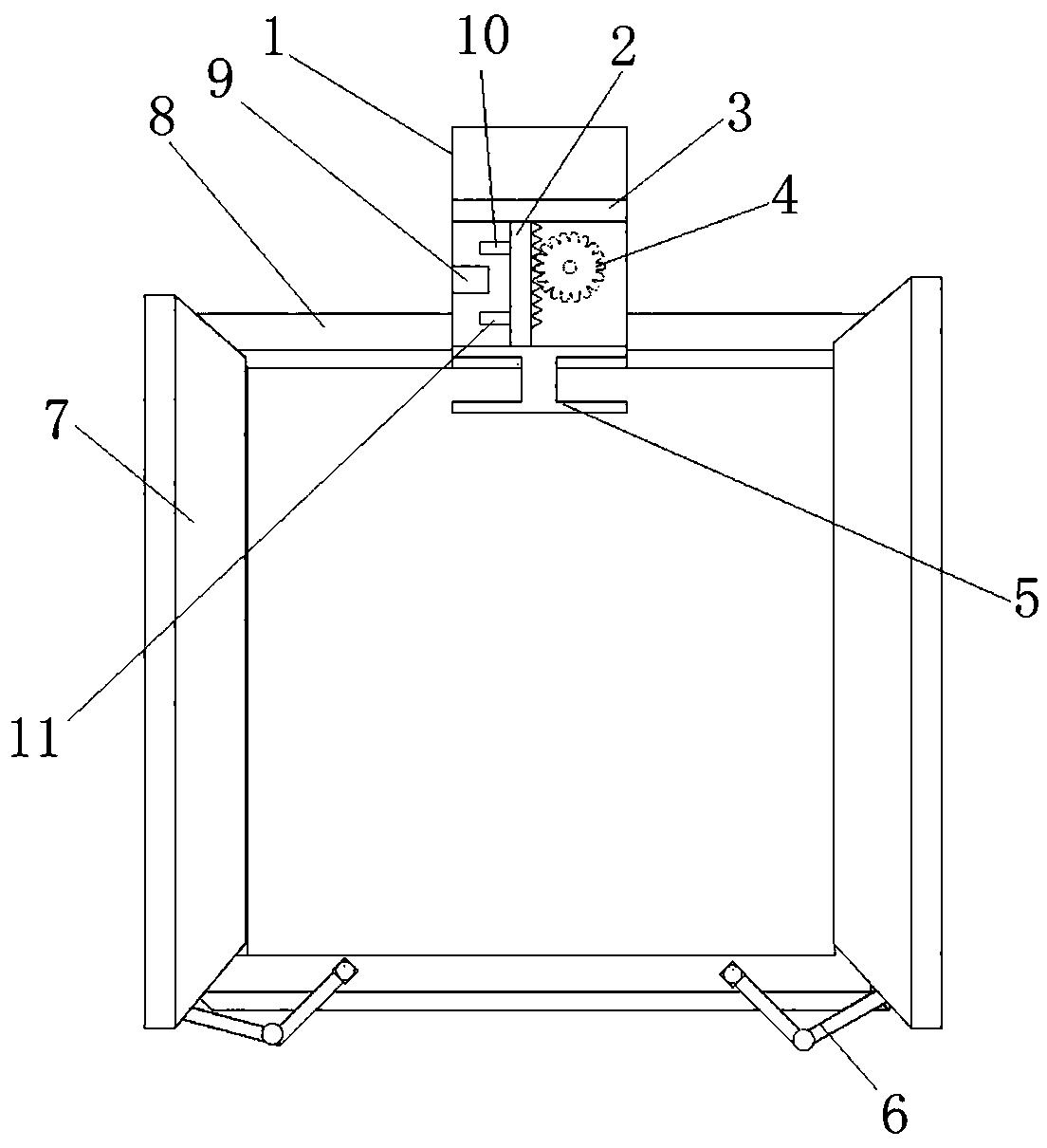

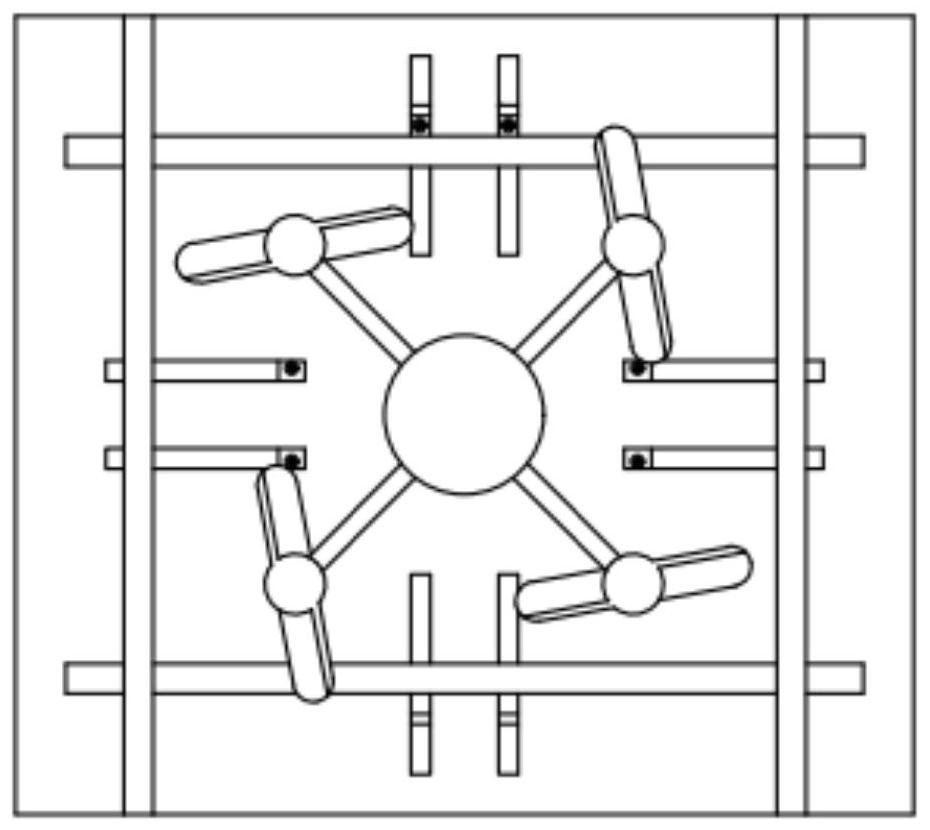

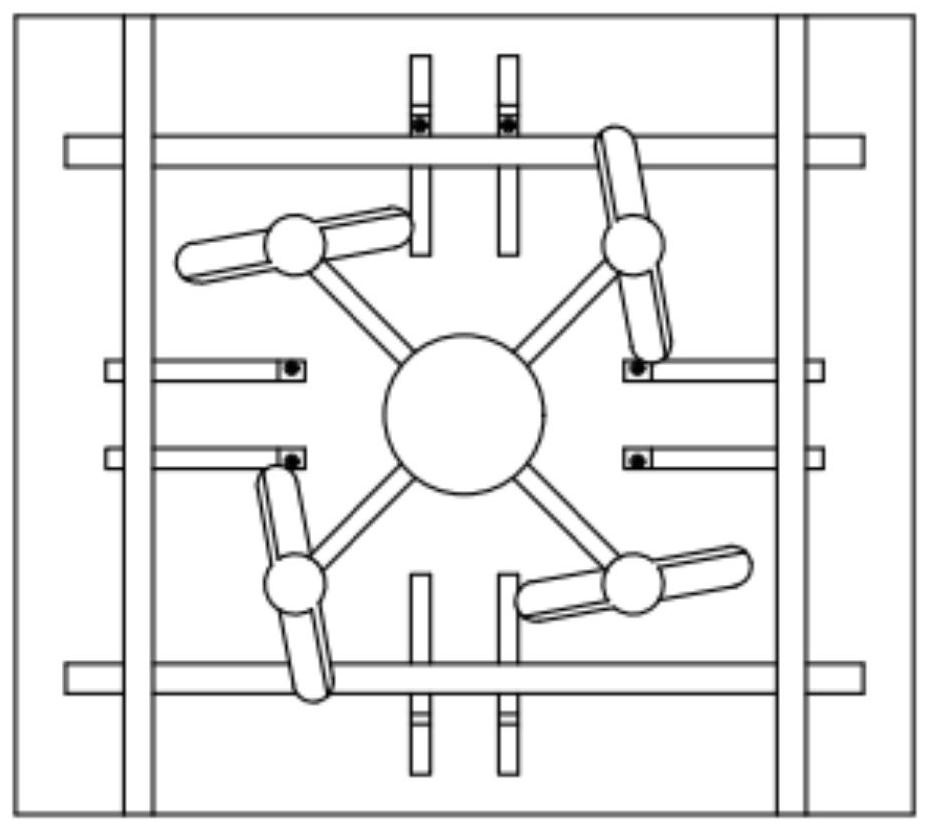

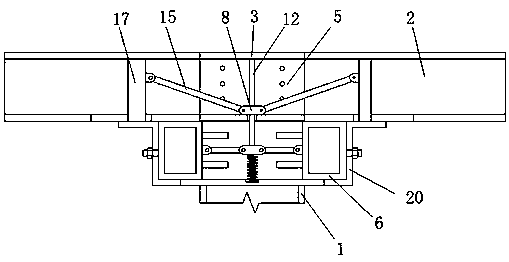

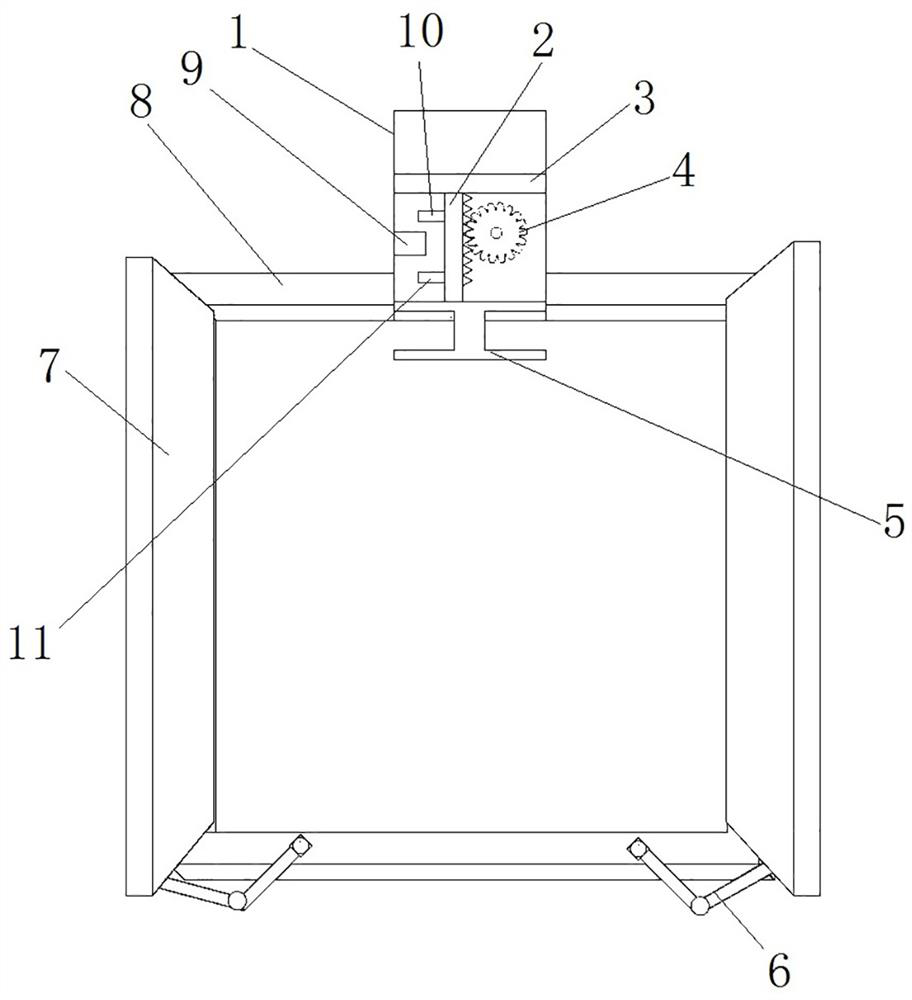

Unmanned aerial vehicle charging device

ActiveCN112572215AReduce R&D and manufacturing costsReduce dependenceCharging stationsElectric vehicle charging technologyUncrewed vehicleGps positioning

The invention provides an unmanned aerial vehicle charging device. The unmanned aerial vehicle charging device comprises an unmanned aerial vehicle charging positioning mechanism and a charging coil transmitting platform, wherein the unmanned aerial vehicle charging positioning mechanism comprises a charging platform transmission device, a bottom plate, an unmanned aerial vehicle landing plate anda positioning device; the charging platform transmission device comprises a front-and-back transmission device and a left-and-right transmission device, and the positioning device comprises a left-and-right positioning device and a front-and-back positioning device. The charging device is advantaged in that the unmanned aerial vehicle lands on the unmanned aerial vehicle landing area after passing through the GPS positioning base station, the unmanned aerial vehicle can be accurately docked with the charging coil transmitting platform through the interaction mode of the unmanned aerial vehicle charging positioning mechanism, the docking mode is simple and efficient, the research and development manufacturing cost of the base station and the unmanned aerial vehicle corresponding module islow, and dependence of the unmanned aerial vehicle on a sensor is reduced.

Owner:涵涡智航科技(玉溪)有限公司

A drone charging device

ActiveCN112572215BReduce R&D and manufacturing costsReduce dependenceCharging stationsElectric vehicle charging technologyUncrewed vehicleGps positioning

Owner:涵涡智航科技(玉溪)有限公司

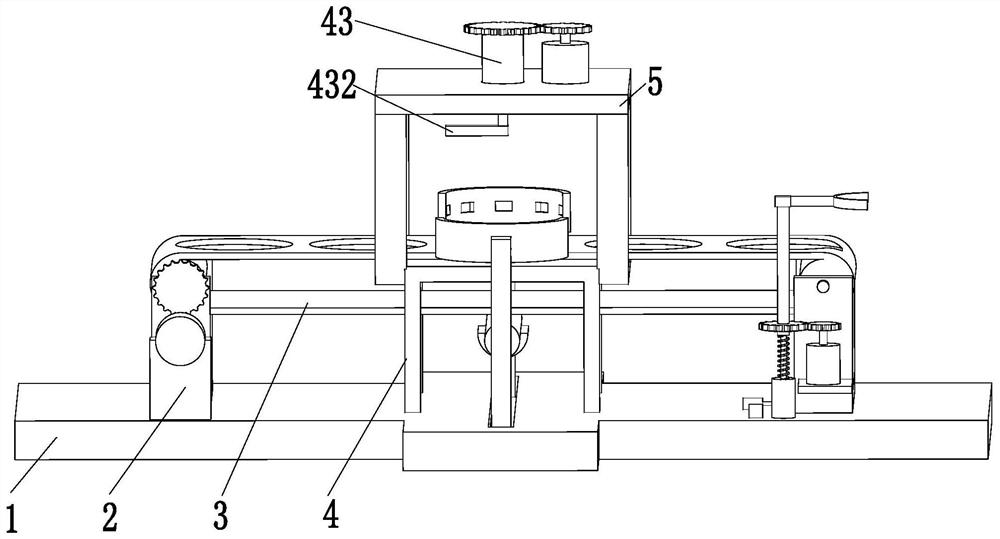

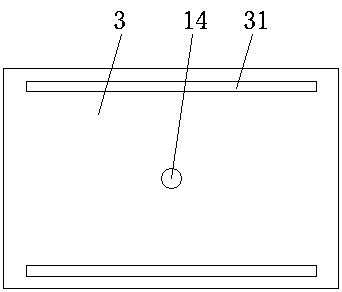

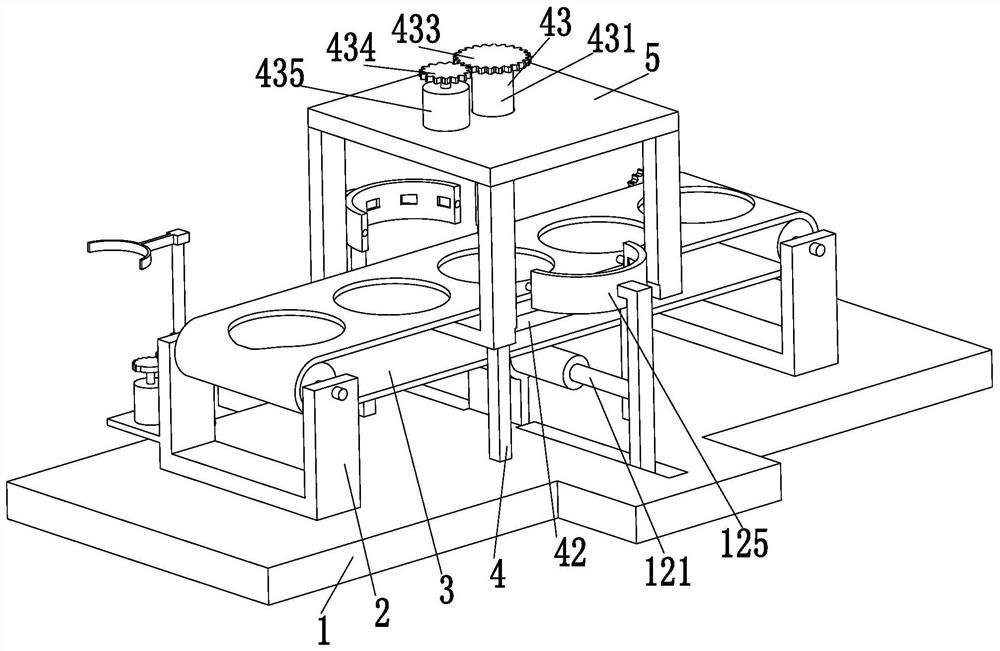

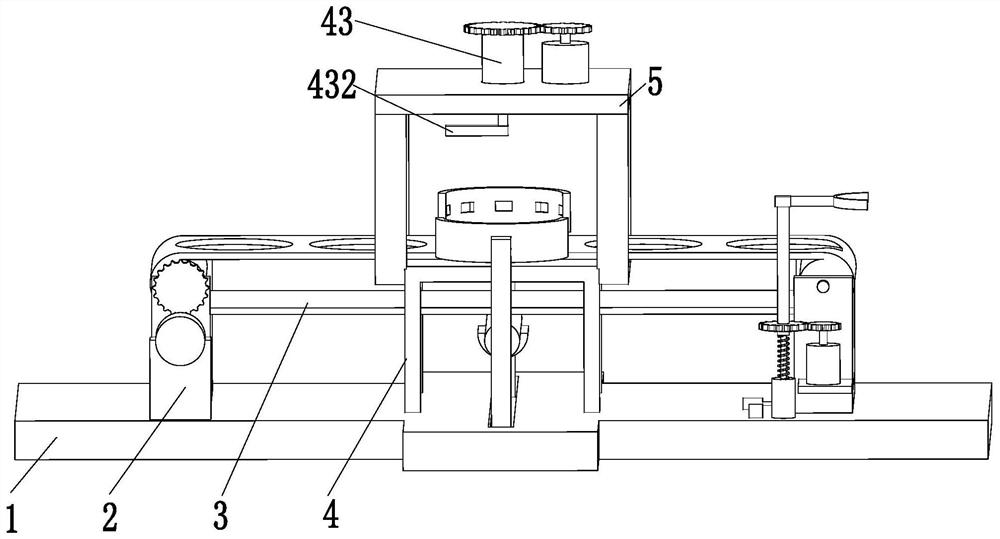

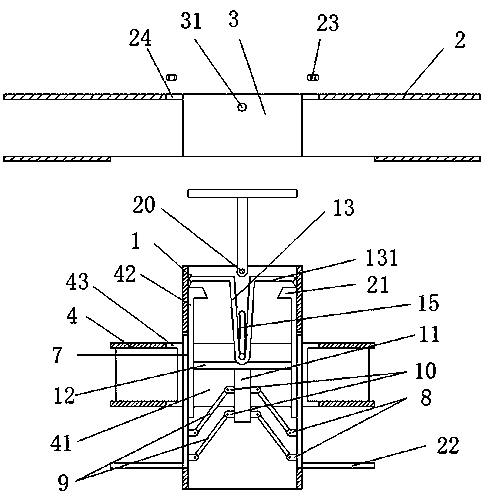

Silicon wafer cleaning system

PendingCN110176419ASimple dockingSemiconductor/solid-state device manufacturingButt jointCleaning station

The invention relates to a silicon wafer cleaning system. The silicon wafer cleaning system comprises a wafer inserting station, a cleaning station, a turnover mechanism, a first rotating mechanism and a conveying rail, wherein the turnover mechanism is used for turning a flower basket loaded with the silicon wafers output by the wafer inserting station to a horizontal state; the first rotating mechanism is used for driving the flower basket which is overturned to the horizontal state to rotate in the horizontal direction at a preset angle; and the conveying rail is used for conveying the flower basket rotated by the first rotating mechanism to the cleaning station. The silicon wafer cleaning system is characterized in that the conveying rail is arranged between the wafer inserting stationand the cleaning station, so that the flower basket loaded with the silicon wafers output by the wafer inserting station is directly conveyed to the cleaning station through the conveying rail afterbeing overturned by the turnover mechanism and rotated by the first rotating mechanism. Only one conveying rail is arranged between the wafer inserting station and the cleaning station, and the problem that the wafer inserting output rail of a traditional wafer inserting machine is not consistent with the feeding structure of a cleaning machine, and the problem that butt joint structure of the wafer inserting machine and the feeding machine is complex can be solved; and in other words, the butt joint mode between the wafer inserting station and the cleaning station is simplified.

Owner:阜宁协鑫光伏科技有限公司

Surface contact type bus device

ActiveCN106005425AIncrease contact areaPoor contactMilitary adjustmentBus networksButt jointContact type

The invention provides a surface contact type bus device. A missile-borne surface contact bus is installed on the surface of an airborne weapon. A missile-borne signal adjustment modulator is connected with the missile-borne surface contact bus. The missile-borne signal adjustment modulator is installed in the airborne weapon. Meanwhile, an airborne surface contact bus is installed in the position, in contact with the missile-borne surface contact bus correspondingly, of the surface of an aircraft. An airborne signal adjustment modulator is connected with the airborne surface contact bus. In addition, the airborne surface contact bus and the missile-borne surface contact bus are each composed of a plurality of contact plates. The contact plates are of a grid structure. The missile-mounted signal adjustment modulator is used for modulating a signal transmitted from the airborne signal adjustment modular and processing the modulated signal into a feedback signal, then the feedback signal is modulated and input into an alternating-current power supply signal provided by the airborne weapon, and therefore communication between a carrying aircraft and the airborne weapon is achieved. The butt joint mode between the carrying aircraft and the airborne weapon is substantially simplified, the integrity of an airborne weapon missile structure is maintained, and the surface contact type bus device is especially suitable for hypersonic platforms and weapons.

Owner:JIANGXI HONGDU AVIATION IND GRP

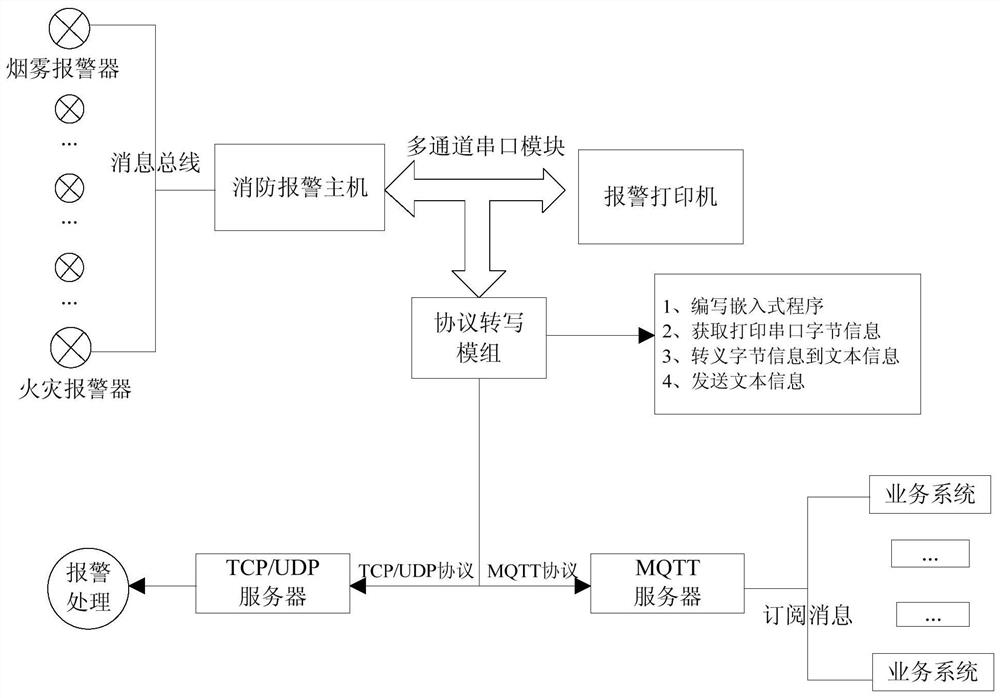

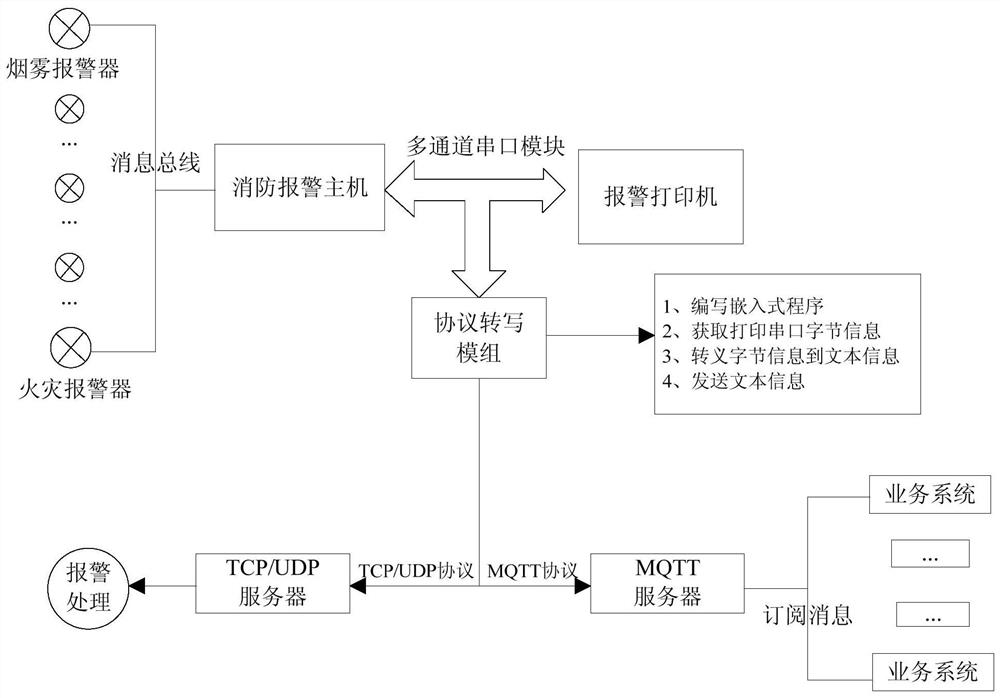

Method and system for monitoring alarm message in real time in intelligent fire fighting

PendingCN113963525ARealize joint defense and joint controlAvoid load pressureAlarmsBus networksAlarm messageComputer printing

The invention discloses a method and a system for monitoring an alarm message in real time for intelligent fire fighting, and the method comprises the steps: providing a protocol transfer module which is connected between a fire fighting alarm host and an alarm printer through a multi-channel serial port module; and the protocol transfer module acquiring the alarm message sent by the multi-channel serial port module, and performing protocol transfer and outward sending of the alarm message. By adding the multi-channel serial port module and the protocol transfer module, the fire-fighting host alarm message can be monitored in real time, and processing of multiple protocols and multiple service scenes is supported. The butt joint mode is more stable, simpler and more flexible, and the load pressure on the main machine of the fire extinguishing system is avoided. By means of the mode, joint defense, linkage and joint control of the fire fighting system can be achieved, and unified management and unified operation of messages can be achieved.

Owner:UNISOUND SHANGHAI INTELLIGENT TECH CO LTD

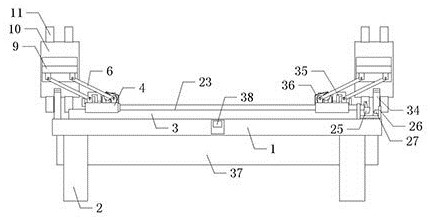

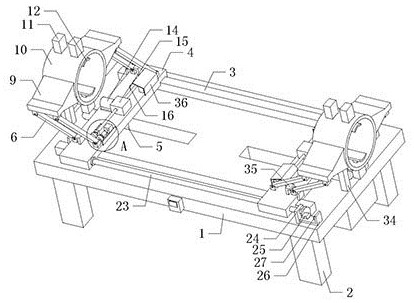

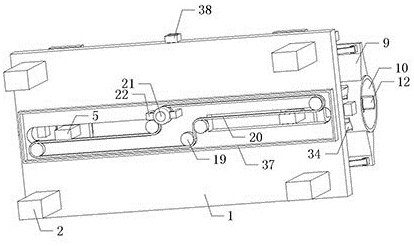

An automatic docking equipment for automobile muffler production

ActiveCN112059515BEasy to isolate and protectAvoid harmWelding/cutting auxillary devicesAuxillary welding devicesMechanical equipmentSlide plate

The invention relates to the technical field of mechanical equipment, in particular to an automatic docking device for the production of automobile mufflers, which can effectively simplify the docking method by performing automatic docking processing on the muffler parts, save physical strength and time during manual operation, and simultaneously The accuracy of the docking position of the muffler parts is improved, the stability and firmness of the parts are improved, which facilitates subsequent welding work, effectively improves product production quality, and improves practicability and reliability; including workbench, four sets of outriggers, two sets of second One guide rail, two sets of slide plates and two sets of push plates. The left and right sides of the middle of the workbench are horizontally provided with through grooves that penetrate up and down. The tops of the four sets of legs are evenly installed on the outside of the bottom of the workbench. The guide rails are installed horizontally on the top front side and the rear side of the workbench respectively.

Owner:山东艾泰克环保科技股份有限公司

A corrugated packaging carton manufacturing molding processing machine and molding processing technology

ActiveCN111805975BImprove stabilityIncrease loading capacityBox making operationsPaper-makingCartonConveyor belt

The present invention relates to a corrugated packing carton making molding processing machine and molding processing technology, comprising a fixed base, a transmission device, a transmission belt, a mounting frame and a mounting plate, the upper end of the fixed base is provided with a transmission device, and the upper end of the transmission device passes through A transmission belt is connected in a sliding fit mode, a mounting frame is installed in the middle of the upper end of the fixed base, and a mounting plate is fixed in the upper end of the mounting frame. The invention can solve the problem that in the traditional round corrugated box forming automatic processing process, glue is often used at the joint between the cylinder and the bottom support. For heavy items, the load-bearing capacity of the glued round corrugated box is relatively low. Poor, it will cause the butt joint of the cylinder and the bottom bracket to fall off, and in the process of processing, it is necessary to manually fix the position of the cylinder and the bottom bracket of the corrugated box, and then deal with the joint, usually lack of joints Pressure-holding treatment, and the manual fixing effect is poor, which is not convenient for automatic production and other problems.

Owner:二十四小时包装科技(深圳)有限公司

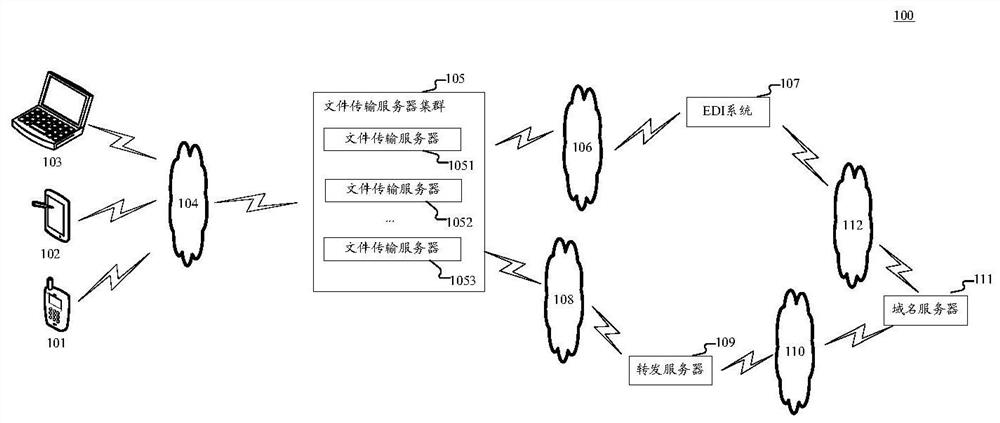

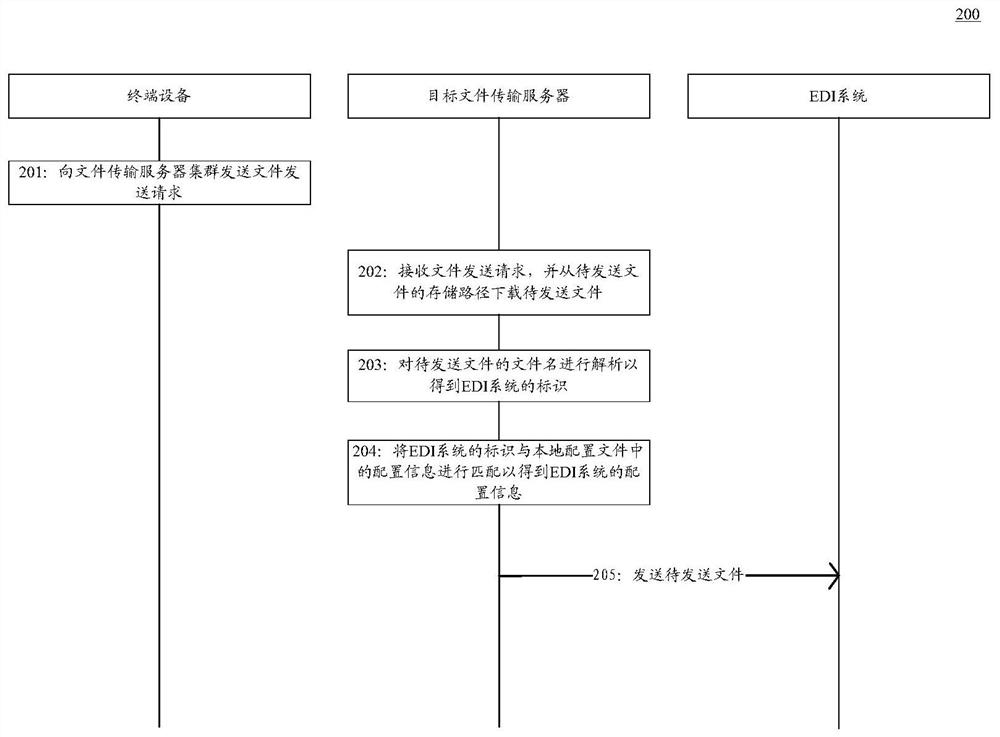

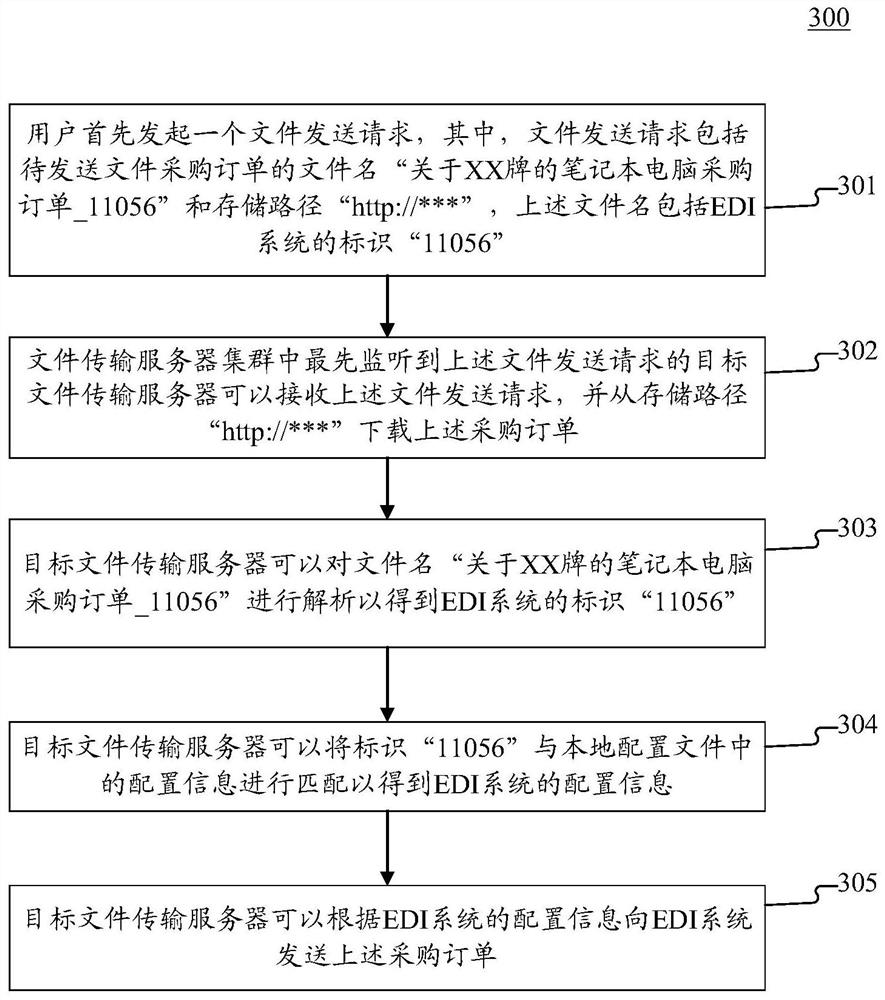

file transfer system

This application discloses a file transfer system. A specific embodiment of the system includes: a terminal device and a file transfer server cluster; the terminal device is configured to: send a file transmission request to the file transfer server cluster, so that the target file transfer server in the file transfer server cluster receives the file transmission request ; The target file transfer server is used to: receive the above-mentioned file sending request, and download the above-mentioned file to be sent from the storage path of the file to be sent; the file name of the file to be sent is analyzed to obtain the identification of the electronic data interchange EDI system; the above-mentioned identification Matching the configuration information in the local configuration file to obtain the configuration information of the EDI system; sending the file to be sent to the EDI system according to the configuration information of the EDI system. This embodiment realizes efficient file transfer.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

A surface contact bus device

ActiveCN106005425BImprove the communication transmission rateSimple dockingMilitary adjustmentBus networksButt jointContact type

A surface contact bus device, wherein the missile-borne surface contact bus is installed on the surface of the airborne weapon, the missile-borne signal adjustment modulator is connected to the missile-borne surface contact bus, and the missile-borne signal adjustment modulator is installed in the airborne weapon; At the same time, the airborne surface contact bus is installed at the corresponding contact position between the aircraft surface and the missile-borne surface contact bus, and the airborne signal adjustment modulator is connected to the airborne surface contact bus; in addition, the airborne surface contact bus and the missile-borne surface contact bus are respectively It is composed of several contact plates, and the contact plate is a grid structure; the missile-borne signal adjustment modulator is used to demodulate the signal sent by the airborne signal adjustment modulator and process the demodulated signal into a feedback signal, and then inject the feedback signal into the In the AC power supply signal provided by the airborne weapon, the communication between the carrier aircraft and the airborne weapon is realized; the docking method between the carrier aircraft and the airborne weapon is greatly simplified, so as to maintain the structural integrity of the airborne weapon body, especially suitable for hypersonic platforms and weapon use.

Owner:JIANGXI HONGDU AVIATION IND GRP

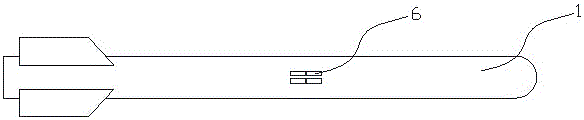

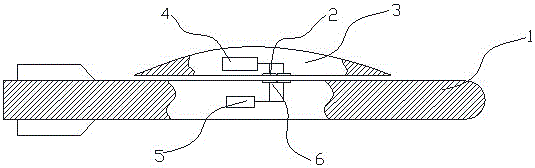

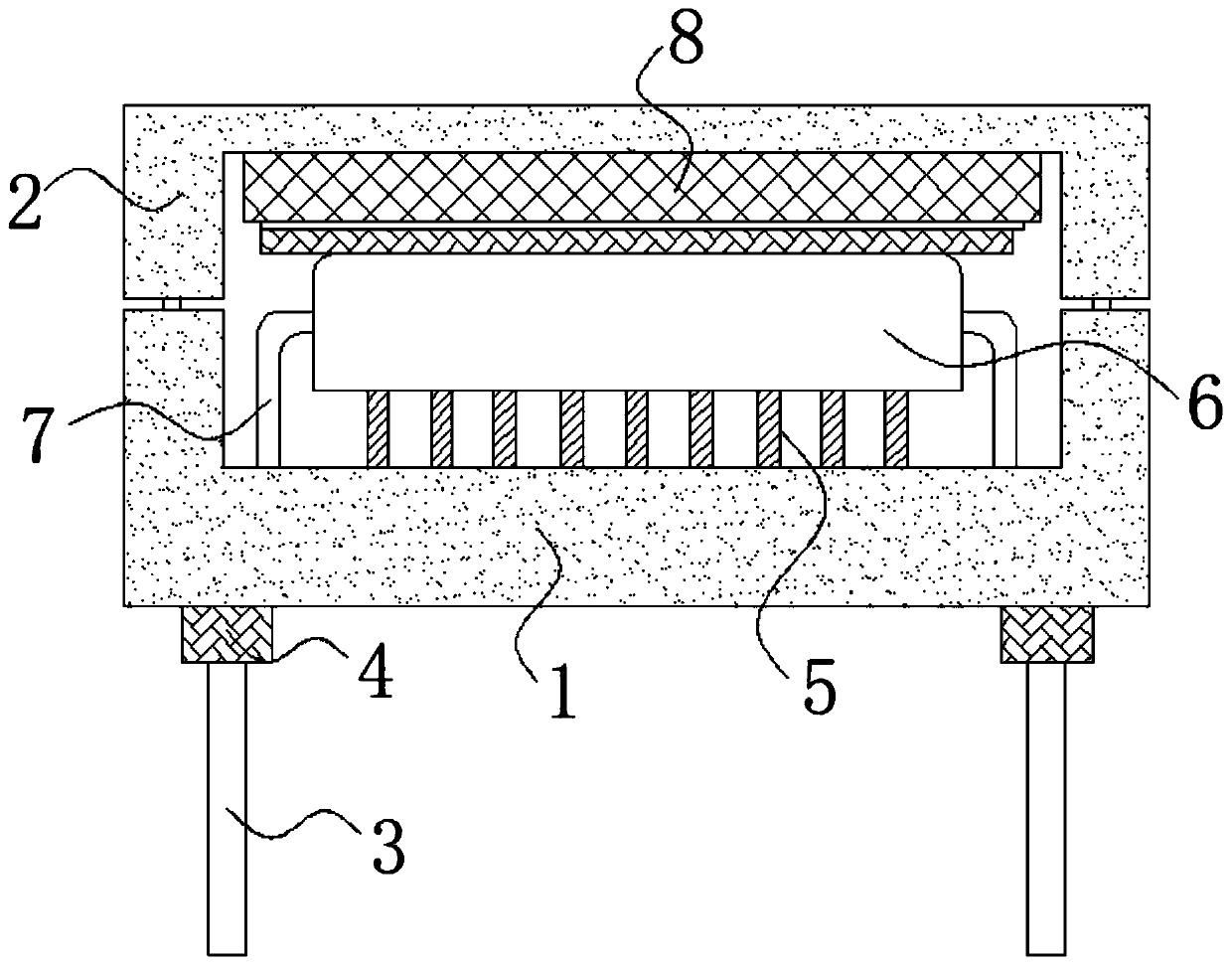

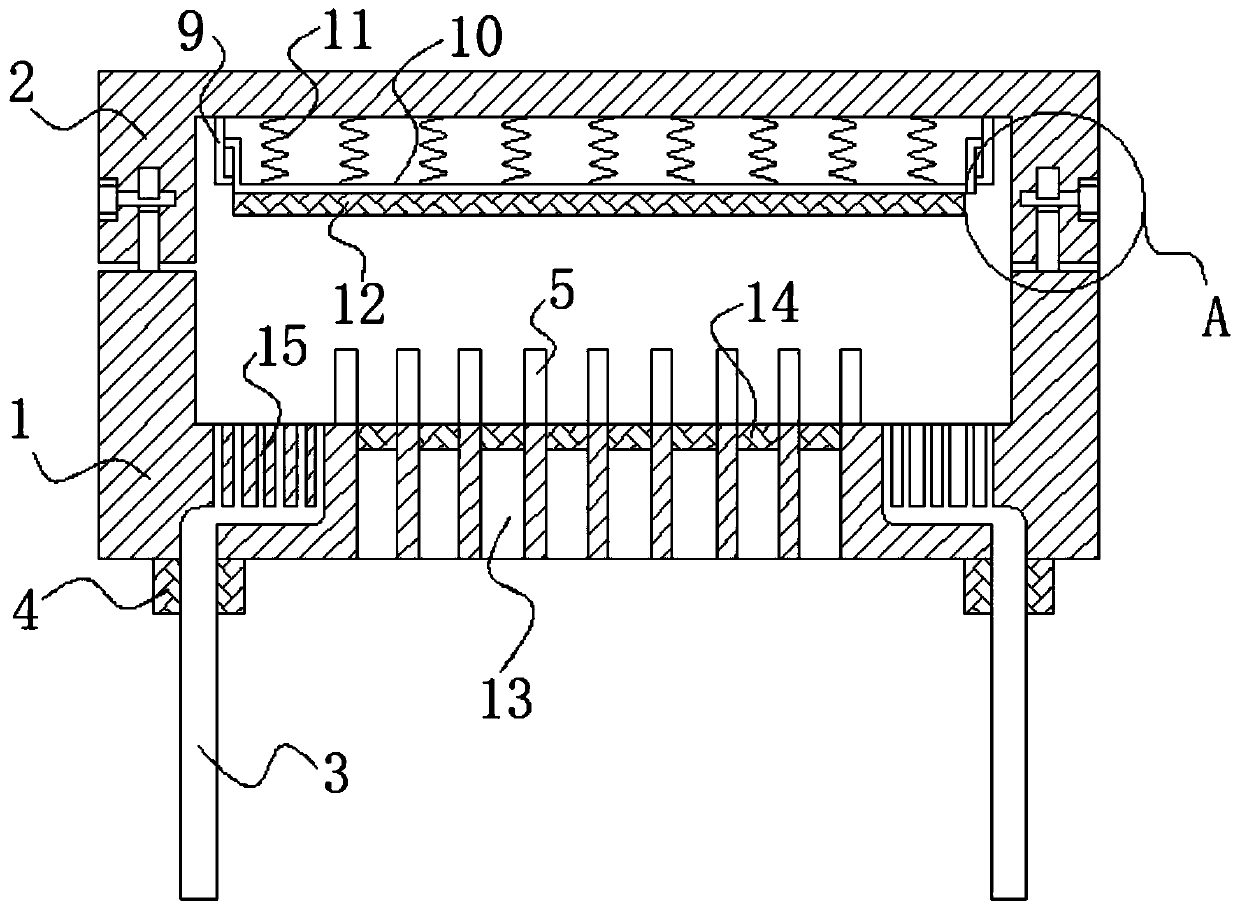

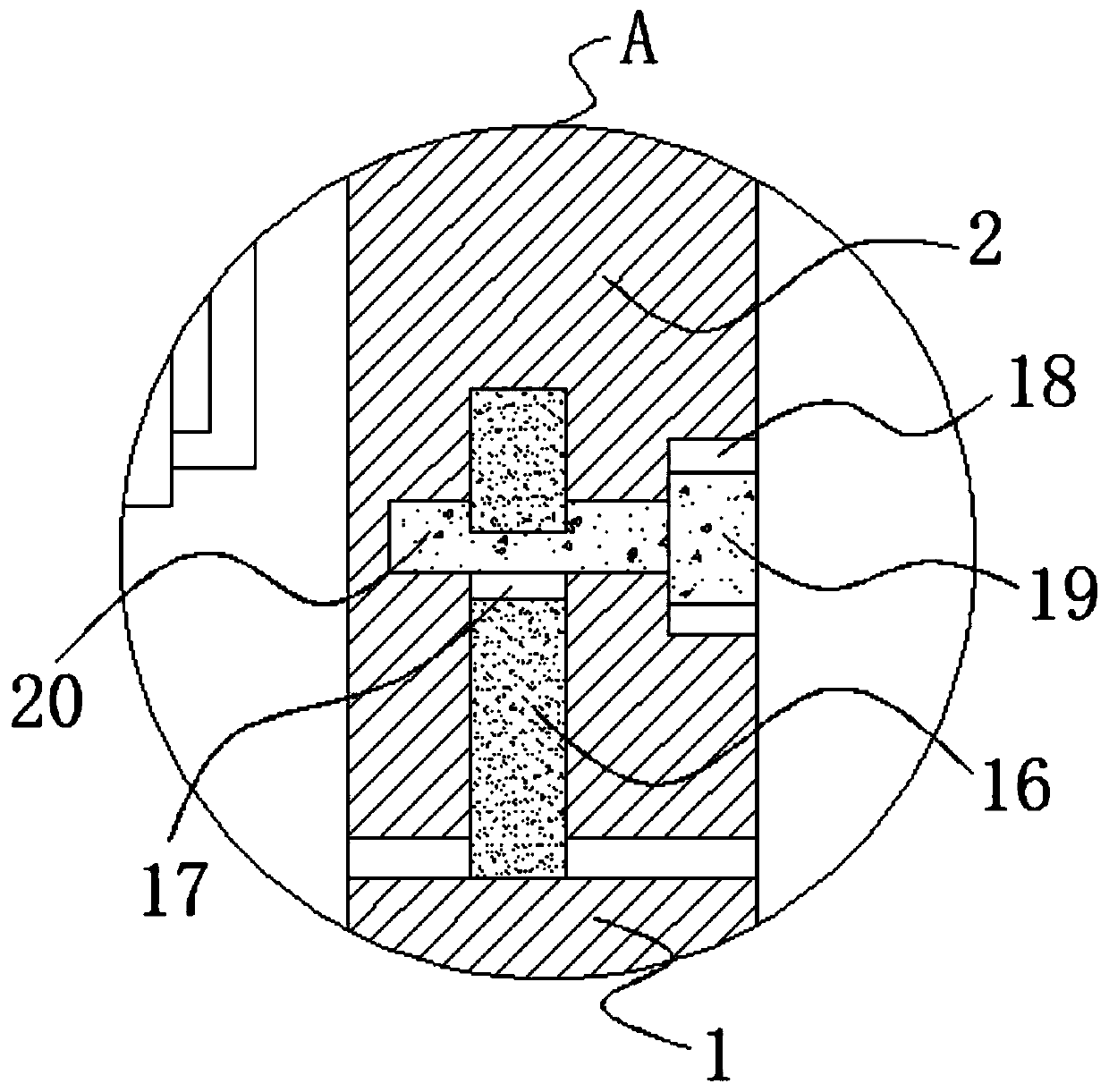

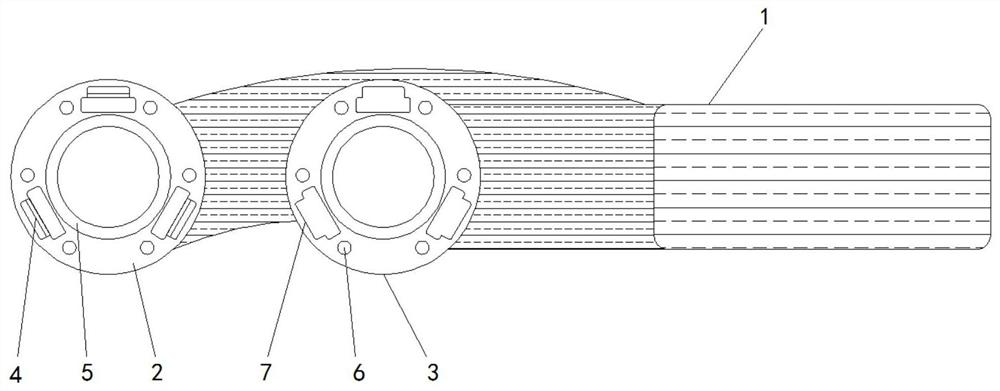

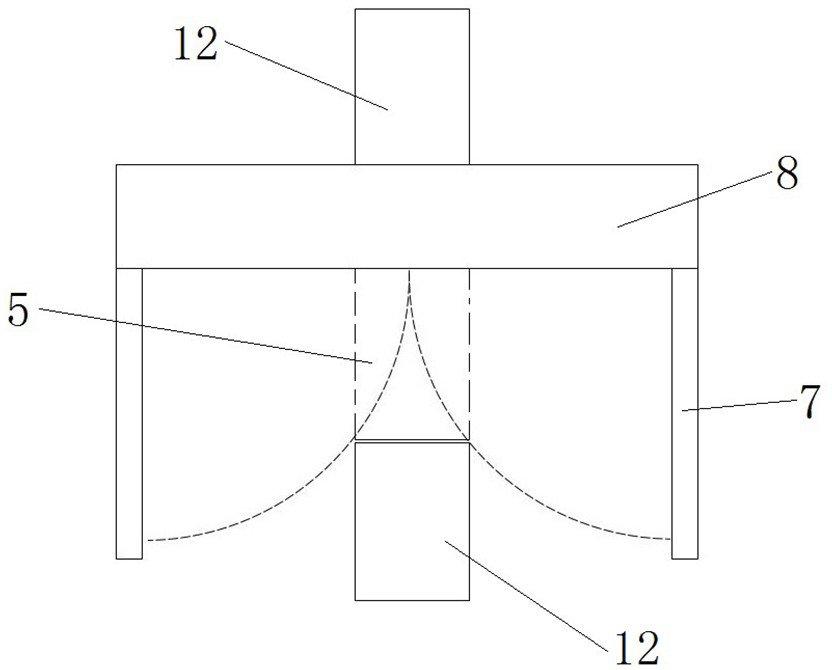

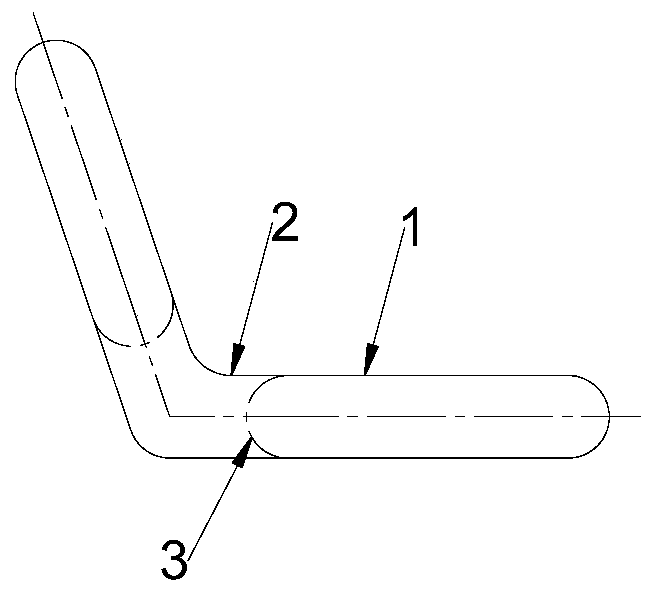

Connecting structure of multi-limb lattice type special-shaped column head and steel beam

ActiveCN110952662ASimple docking and installationReliable connection strengthBuilding constructionsSteel platesSteel columns

The invention discloses a connecting structure of a multi-limb lattice type special-shaped column head and a steel beam. The connecting structure comprises a steel column (1) and two cross beams (2),wherein the two cross beams (2) are connected and fixed into a whole through a beam sleeve (3); two insertion grooves (31) are formed in the position of the lower bottom surface of the beam sleeve (3); an axial positioning device is arranged on the top of the steel column (1), and comprises a steel plate (4) vertically welded in the position of the upper end surface of the steel column (1); positioning plates (5) capable of realizing clearance insertion connection fit with the insertion grooves (31) are vertically welded and fixed at the two sides of the upper top surface position of the steelplate (4); the positioning plates (5) and the beam sleeve (3) are fixed into a whole through screw bolts; and a radial positioning device is arranged between the two positioning plates (5). The connecting structure has the advantages that the butt joint and installation modes are simple; the gravity of the cross beams is used, so that the combination intensity among the beams, columns and haunched beams is improved; meanwhile, the connection intensity is stable and reliable; and the population of the connecting structure in assembled building application is facilitated.

Owner:SHANGHAI GREENLAND CONSTR GRP

A connection structure between multi-leg lattice structure special-shaped column head and steel beam

ActiveCN110952662BHigh bonding strengthSimple dockingBuilding constructionsClassical mechanicsStructural engineering

The invention discloses a connection structure between a multi-leg lattice type special-shaped column head and a steel beam, which comprises a steel column (1) and two beams (2), and the two beams (2) are connected by beam sleeves (3) fixed into one body, two slots (31) are provided on the lower bottom surface of the beam sleeve (3), and an axial positioning device is installed on the top of the steel column (1); the axial positioning device includes a vertical The steel plate (4) welded on the upper end surface of the steel column (1), the two sides of the upper top surface of the steel plate (4) are respectively vertically welded and fixed with a positioning plate (5) that can be inserted and matched with the slot (31) , the positioning plate (5) is fixed integrally with the beam sleeve (3) through bolts, and a radial positioning device is arranged between the two positioning plates (5). The present invention has simple docking and installation methods, utilizes the gravity of the crossbeam to improve the bonding strength among beams, columns and haunched beams, and at the same time, the connection strength is stable and reliable, which is beneficial to its popularization in the application of prefabricated buildings.

Owner:SHANGHAI GREENLAND CONSTR GRP

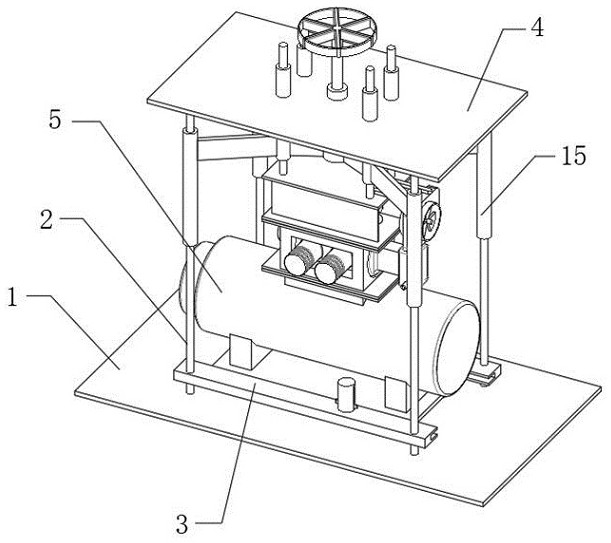

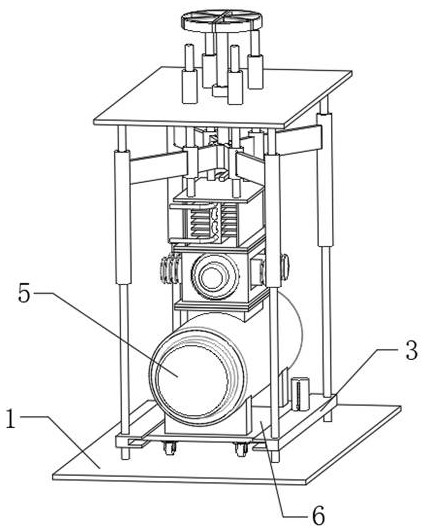

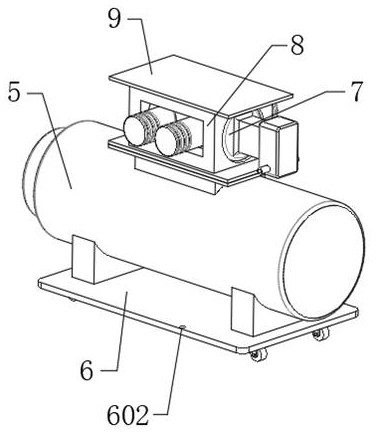

Safe, stable and efficient heat dissipation type air compressor and control method thereof

InactiveCN113969885APromote absorptionAvoid burnsPositive displacement pump componentsPump installationsEngineeringAir compressor

The invention relates to the technical field of air compressors, and discloses a safe, stable and efficient heat dissipation type air compressor and a control method thereof. According to the technical scheme, the safe, stable and efficient heat dissipation type air compressor comprises a bearing bottom plate, an air compressor air storage tank body and an efficient radiator heat conduction shell, wherein a reinforcing supporting stand column is fixedly connected to the top of the bearing bottom plate, and a bearing top plate is fixedly connected to the top of the reinforcing supporting stand column. According to the safe, stable and efficient heat dissipation type air compressor, heat absorbed by the efficient radiator heat conduction shell can be rapidly dissipated through the arrangement of heat dissipation fins and a heat dissipation fan body; for the air compressor used for a long time, the heat dissipation fins ensure that the contact area between air and the efficient radiator heat conduction shell is large through the heat dissipation fins, so that the heat dissipation effect is good, heat accumulation and high-temperature operation of the air compressor caused by long-time use are avoided, the phenomenon that an internal circuit is burnt out or a fire disaster occurs is avoided, the safety of the device can be guaranteed, and stable operation of the air compressor is guaranteed.

Owner:於赵勰

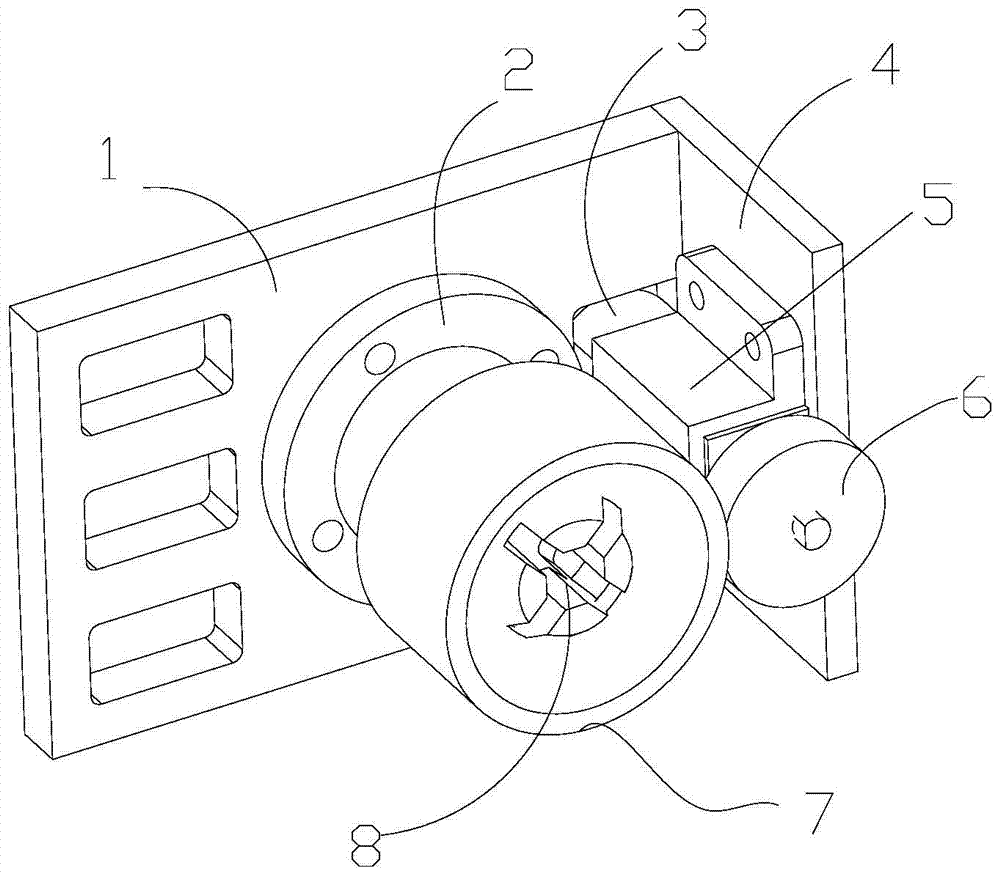

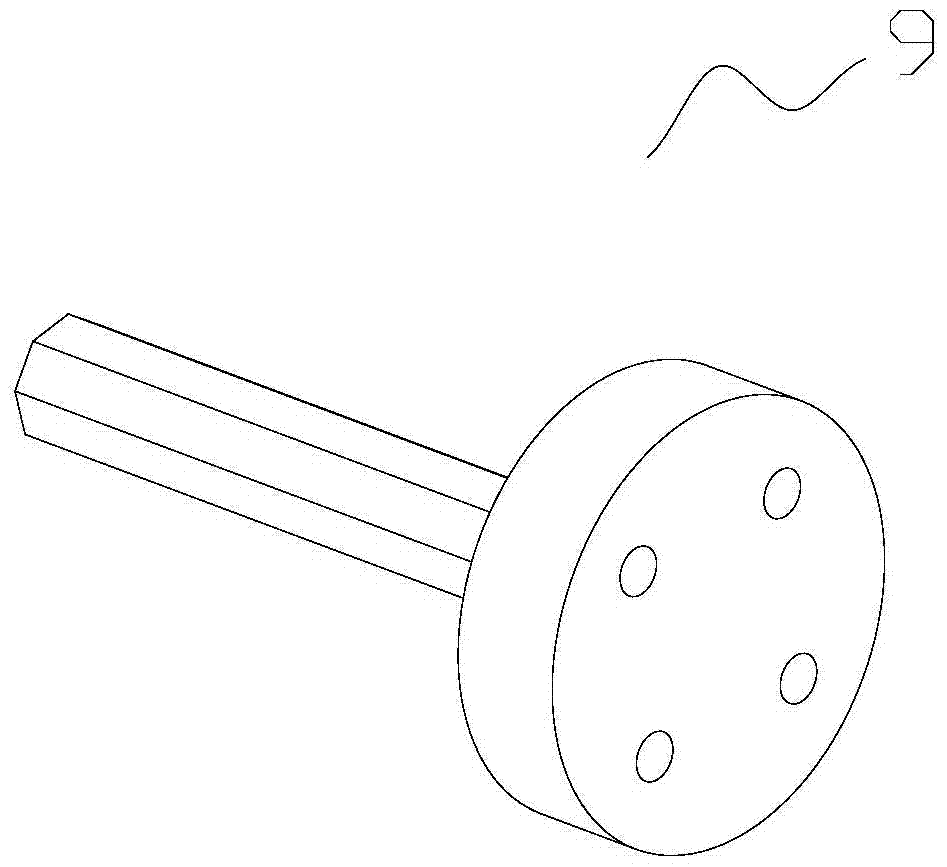

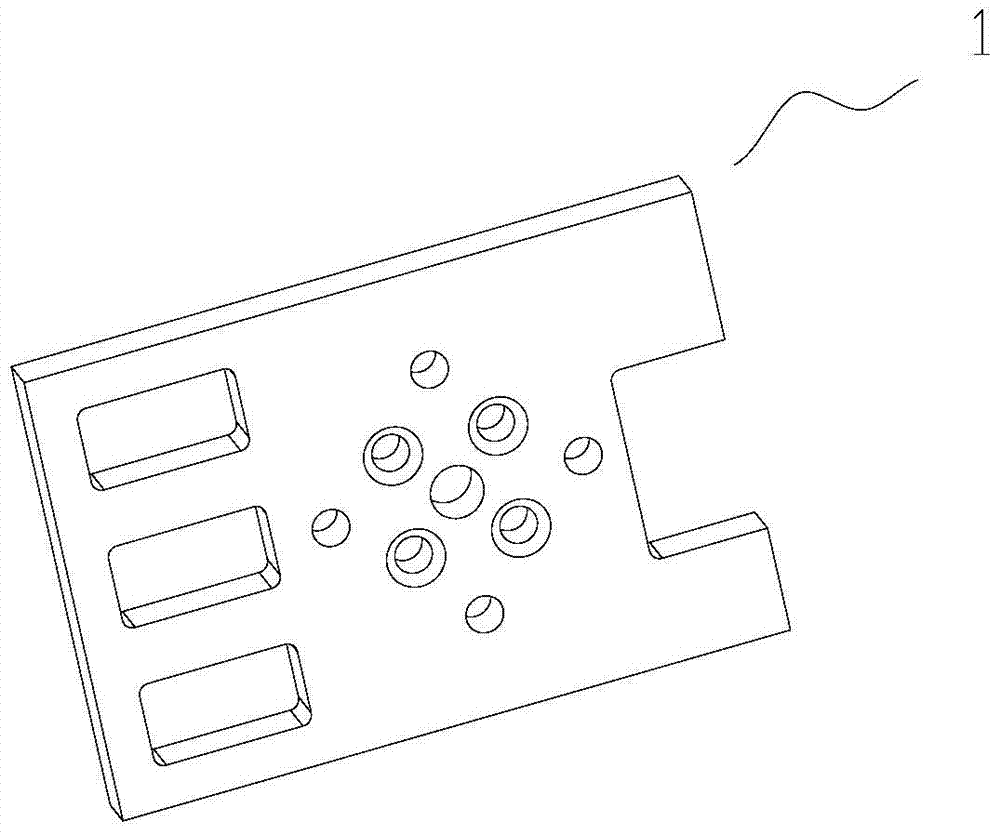

Mounting structure of electronic component

InactiveCN110769623ATo achieve a fixed connection positionThere will be no phenomenon of displacement and sheddingCasings/cabinets/drawers detailsSmall component housingsEngineeringStructural engineering

The invention discloses a mounting structure of an electronic component. The mounting structure comprises a mounting base, connecting inserting rods are fixedly connected with the two sides of the lower surface of the mounting base respectively, and can be fixedly connected on the surface of a PCB, the upper end of the mounting base is fixedly connected with an upper cover, heat dissipation platesare fixedly arranged at the middle portion of the inner surface of the mounting base and are fixedly arranged at the upper portion of the inner surface of the mounting base at an equal intervals, andvent holes are fixedly formed in the upper surface of the mounting base and penetrate the lower surface of the mounting base. In the present invention, the mounting structure of the electronic component is directly fixed on the PCB, the electronic component is fixed in the structure to achieve fixing of the position of the electronic component, and connecting insertion holes with different distances are fixedly formed in the structure and matched with joint operation of the upper compression part, so that fixed connecting positions are provided for electronic components of different sizes; and moreover, the upper portion and the lower portion of the structure are fixedly arranged in a butt joint mode, butt joint holes are formed in the structure, the butt joint mode is simple, and simpledisassembling, maintaining and replacing operation is achieved.

Owner:徐州陀微传感科技有限公司

Fire hose convenient to connect

PendingCN113007476AFirmly connectedSoft lightPipe couplingsCouplingsEngineeringStructural engineering

The invention relates to the technical field of fire hoses, and discloses a fire hose convenient to connect. The fire hose comprises a fire hose body, wherein the two ends of the fire hose body are fixedly connected with a connector and a sleeve head correspondingly, and a buckle is fixedly installed on the front face of the connector. According to the fire hose convenient to connect, noctilucent plates are fixedly installed on the front face of the connector and the front face of the sleeve head, the number of the noctilucent plates is twelve, the twelve noctilucent plates are equally divided into two groups to be installed on the front face of the connector and the front face of the sleeve head correspondingly, and every two noctilucent plates in each group form a pair and are distributed on the left side and the right side of the buckle and the left side and the right side of a clamping groove correspondingly; even in a dark environment, fluorescent light emitted by the noctilucent plates facilitates a common person to quickly find a butt joint point in the dark and then quickly butt joint a plurality of fire hose bodies, during butt joint, the buckle is aligned with the clamping groove and inserted into the clamping groove, then the buckle is rotated by 60 degrees, a trapezoidal clamping block can be automatically clamped on two compression spring supports, the butt joint mode is simple and quick, and the time can be effectively saved.

Owner:扬州双星消防科技有限公司

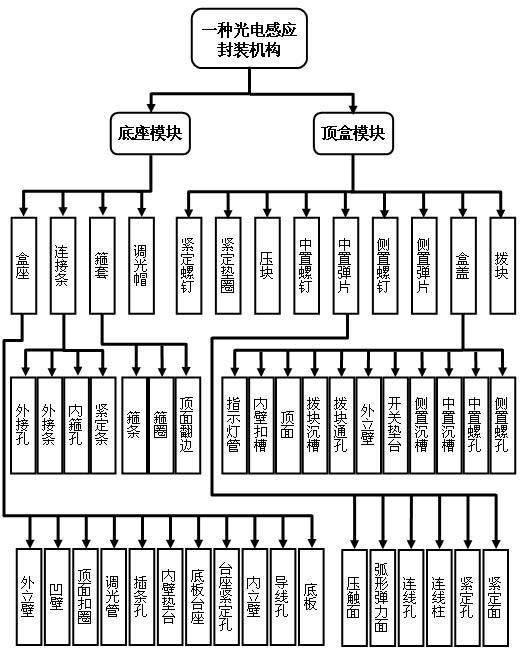

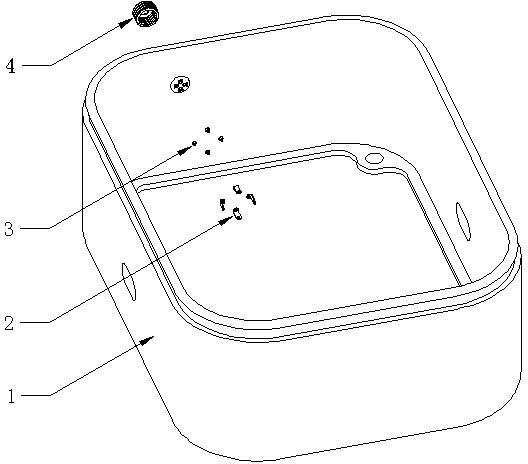

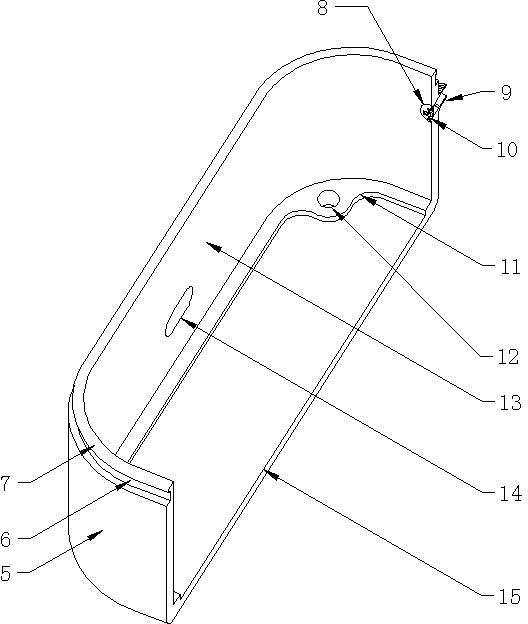

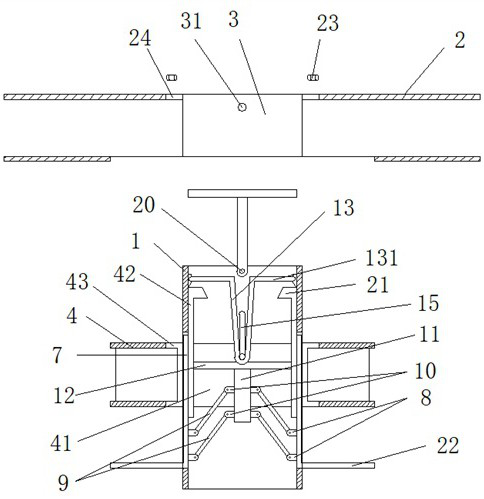

Photoelectric packaging mechanism

InactiveCN102595820AMeet the needs of useWide adaptabilityCasings/cabinets/drawers detailsSet screwChemical industry

The invention relates to a box type packaging mechanism, and particularly relates to a box type packaging mechanism which can bidirectionally turn on and turn off a power source and has a photoelectric sensing function. The box type packaging mechanism disclosed by the invention consists of two modules, namely, a base and a top box, comprising thirteen parts, namely, a box base, a connecting strip, a hoop, a light adjusting cover, set screws, a fastening washer, a press block, a centrally-arranged screw, a centrally-arranged elastic plate, a side screw, a side elastic plate, a box cover, a shifting block and the like. A packaging closing device for electronic component circuits has the characteristics of being capable of bidirectionally turning on and turning off a power supply, retaining external elements, adjusting the lightness of light, and being wide in adaptability. The packaging mechanism is widely applied in working environments, such as plains, mountainous areas, hills, islands, high altitude and the like, and accords with the use requirements of electric industry, mechanical industry, chemical industry and the like, and has the advantages of easiness in operation and manufacturing, beautiful appearance of formed products, solid and durable structure, use convenience, wide marketing space, and high application value and additional economic value.

Owner:CETC NINGBO MARINE ELECTRONICS RES INST

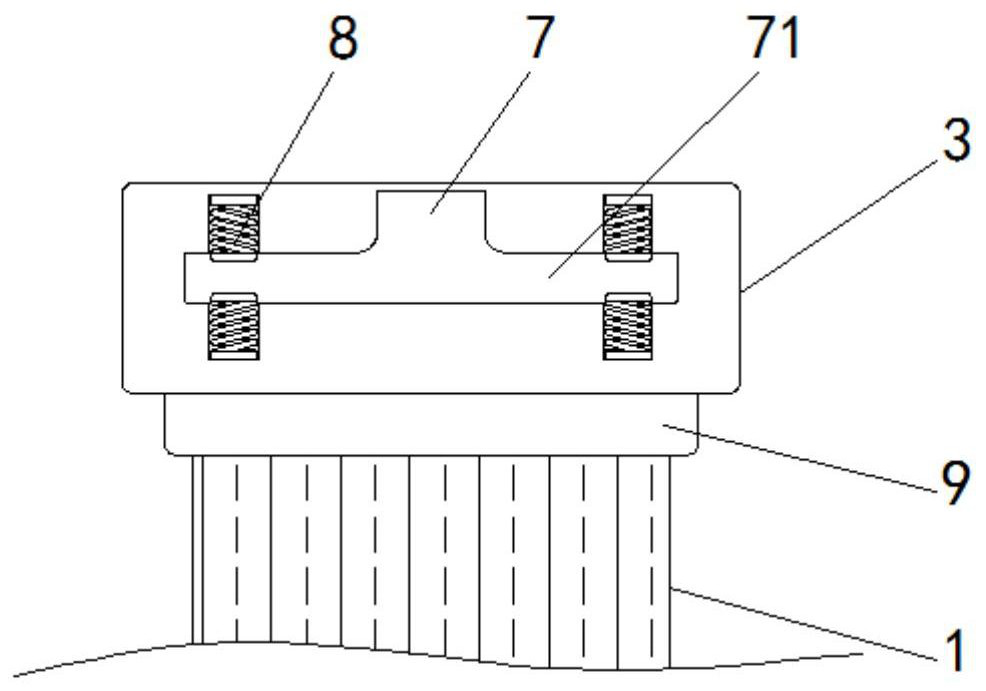

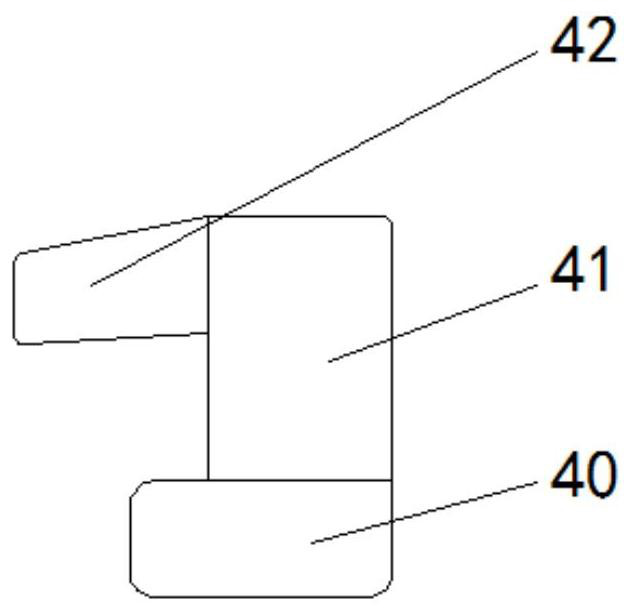

A special-shaped column-beam-column joint structure

ActiveCN110984374BHigh bonding strengthSimple dockingBuilding constructionsClassical mechanicsMechanical engineering

The invention discloses a special-shaped column-beam-column joint structure, which comprises a square column (1) with a rectangular tubular structure in section and two beams (2), and the two beams (2) are connected and fixed by a sleeve (3) Integrate, the sleeve (3) can be socketed and matched with the square column (1) with an axial gap, and the two sides of the square column (1) are respectively provided with axillary beams (4) located below the cross beam (2), The ends of the added haunch beams (4) can be attached to the outer side of the square column (1) and slide; the two added haunch beams (4) are connected and fixed into one body through two parallel guide plates (41). The two ends of the guide plate (41) are respectively welded and fixed with positioning baffles (42) that can slide against the inner wall of the square column (1). The present invention has simple docking and installation methods, utilizes the gravity of the crossbeam to improve the bonding strength among beams, columns and haunched beams, and at the same time, the connection strength is stable and reliable, which is beneficial to its popularization in the application of prefabricated buildings.

Owner:SHANGHAI GREENLAND CONSTR GRP

A fire door system

ActiveCN110778256BSimple moving trackImprove docking accuracyFireproof doorsPower-operated mechanismClassical mechanicsFire door

The present invention relates to a fireproof door system. The fireproof door system includes: a door frame, a fireproof door is movably installed in the doorway of the doorframe; a docking track is controlled to move to the doorway to dock with the fixed track after the fireproof door is opened; before the fireproof door is closed, It is controlled to be removed from the door opening; the fire door system also includes: a receiving groove, corresponding to the door opening along the extension direction perpendicular to the fixed track, and arranged outside the door opening, the receiving groove can accommodate the docking track, and the receiving groove is set on the door frame The inner surface of the housing or the receiving groove runs through the door frame, and the receiving groove has a notch facing the door opening along the extending direction perpendicular to the fixed track; the linear drive mechanism is located in the receiving groove and has a linear output end connected to the docking track. The linear drive mechanism The docking track can be driven to move to the door opening through the notch and be removed from the door opening and retracted into the receiving groove. Compared with the prior art, the docking accuracy is improved to ensure that the docking track can be docked with the fixed track.

Owner:XJ ELECTRIC +2

Corrugated packaging carton manufacturing, moulding and processing machinery and moulding forming process

ActiveCN111805975AImprove stabilityIncrease loading capacityPaper-makingBox making operationsCartonIndustrial engineering

The invention relates to corrugated packaging carton manufacturing, moulding and processing machinery and a moulding forming process. The corrugated packaging carton manufacturing, moulding and processing machinery comprises a fixed base, a transfer device, a transfer belt, a mounting frame and a mounting plate, wherein the upper end of the fixed base is provided with the transfer device; the upper end of the transfer device is connected to the transfer belt in a sliding fit mode; the middle part of the upper end of the fixed base is equipped with the mounting frame; and the upper end of the mounting frame is fixedly equipped with the mounting plate. The corrugated packaging carton manufacturing, moulding and processing machinery can solve the problems that drop at a butt-joint of a cylinder and a bottom support is caused as load bearing ability for glued circular corrugated cartons is relatively poor for relatively heavy objects if a gluing way is adopted for the butt-joint of cylinders and the bottom supports in a conventional automatic processing process for circular corrugated carton moulding, and manual fixing effect is relatively poor, automatic production is inconvenient andthe like as the cylinders and the bottom supports of the corrugated cartons need to fix in position manually, joints need to process in a processing process, and pressure-maintaining treatment on thejoints is generally absent.

Owner:二十四小时包装科技(深圳)有限公司

A robot self-assembly docking device

Owner:SHENZHEN TAIYANG TECH CO LTD

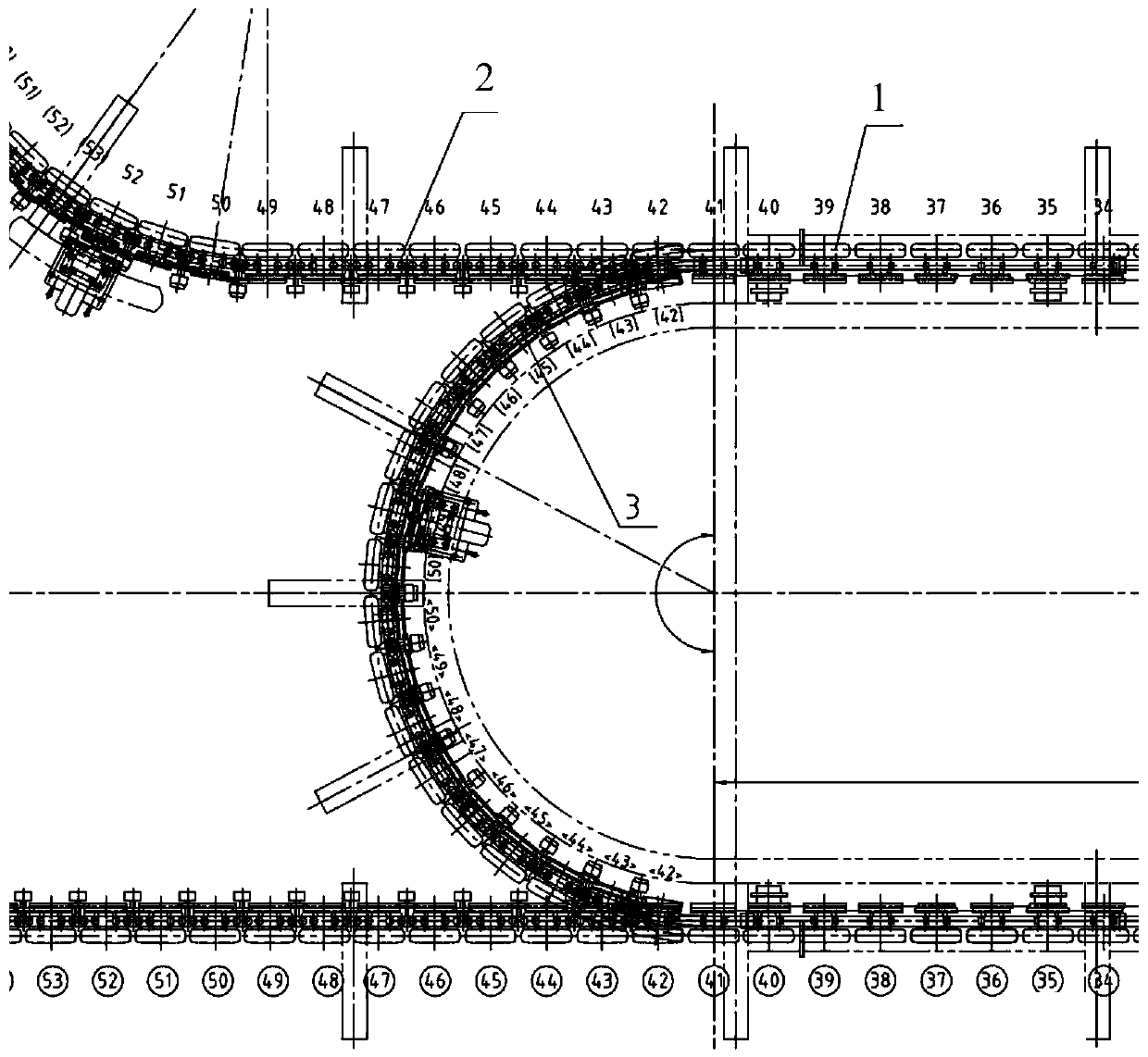

Support beam switching device

The invention relates to the technical field of cableway, and discloses a support beam switching device. The support beam switching device is used for butt joint between a first support beam and a second support beam or between the first support beam and a third support beam. The support beam switching device comprises a positioning device; the positioning device comprises a pin shaft assembly anda plug pin seat assembly; the first support beam is connected with the pin shaft assembly or the plug pin seat assembly; the second support beam and the third support beam are each provided with thepin seat assembly matched with the pin shaft assembly or the pin shaft assembly matched with the pin seat assembly; the pin shaft assemblies comprise linear driving parts, positioning seats and pin shafts; the output ends of the linear driving parts are connected with the first ends of the pin shafts; the pin shafts penetrate through the positioning seats, and the second ends of the pin shafts canextend out of positioning bosses at the end parts of the positioning seats; the positioning bosses are coaxial with the pin shafts; the plug pin seat assemblies comprise plug pin seats; the plug pinseats comprise positioning grooves matched with the positioning bosses and pin shaft holes matched with the pin shafts; and the positioning grooves are coaxial with the pin shaft holes. The supportingbeam switching device is simple and compact in structure and saves installation space.

Owner:BEIJING MATERIALS HANDLING TECH INST CO LTD

Special-shaped column beam and column node structure

The invention discloses a special-shaped column beam and column node structure. The special-shaped column beam and column node structure comprises a square column (1) with a rectangular tubular structure in cross section and two cross beams (2), wherein the two cross beams (2) are connected and fixed into a whole through a sleeve (3), the sleeve (3) can be in sleeve connection and matched with anaxial clearance of the square column (1), haunched beams (4) located below the cross beams (2) are arranged at the two sides of the square column (1), and the end parts of the haunched beams (4) can be attached to the outer side surface of the square column (1) to slide; and the two haunched beams (4) are connected and fixed into a whole through two guide plates (41) arranged in parallel, and positioning baffles (42) capable of being attached to the inner wall of the square column (1) to slide are welded and fixed to the two ends of the guide plates (41) correspondingly. According to the special-shaped column beam and column node structure, the butt joint and the mounting mode are simple, the gravity of the cross beams is used for improving the combined strength among the beams, the columnand the haunched beams, the connection strength is stable and reliable at the same time, and the special-shaped column beam and column node structure is beneficial to popularization in the prefabricated building application.

Owner:SHANGHAI GREENLAND CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com