A corrugated packaging carton manufacturing molding processing machine and molding processing technology

A technology for forming processing and cartons, which is applied in the direction of container manufacturing machinery, packaging, transportation and packaging, etc. It can solve the problems of affecting the quality of round corrugated cartons, falling off of the joint between the cylinder and the bottom bracket, and poor fixing effect, etc., to achieve fast loading Integrated treatment of nail butt joints, improving stability and load capacity, and ensuring the effect of quality in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

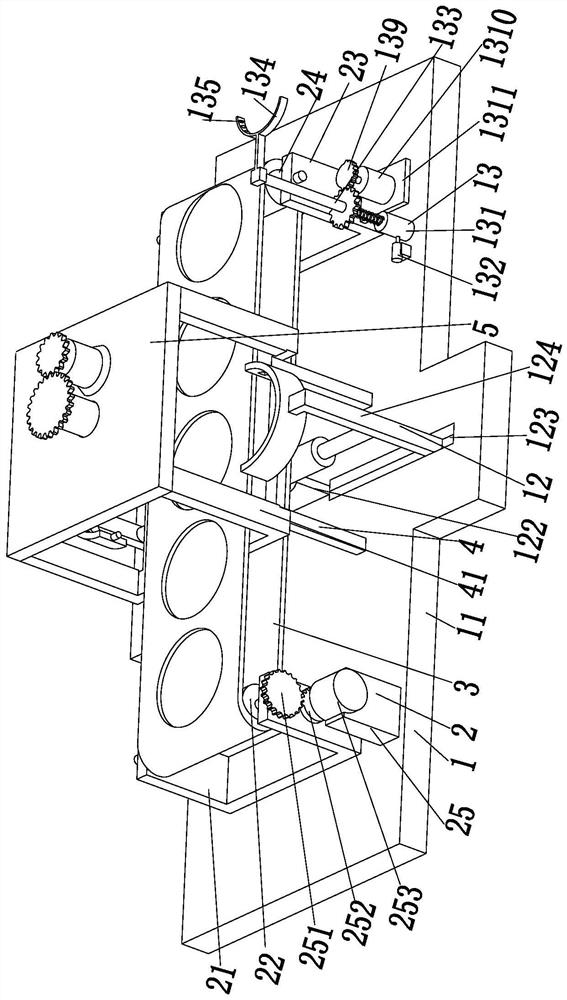

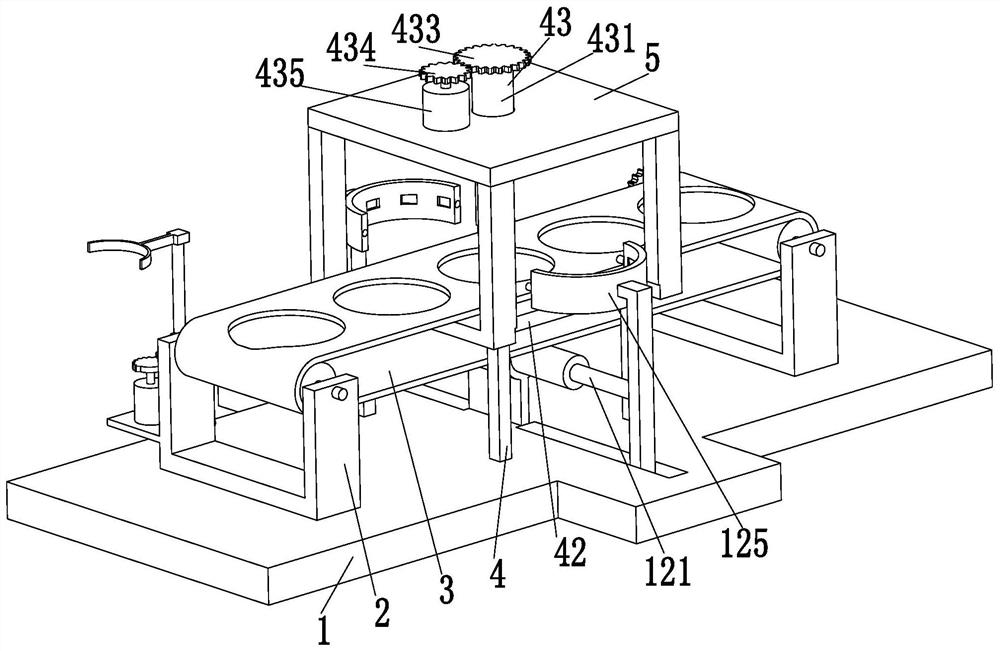

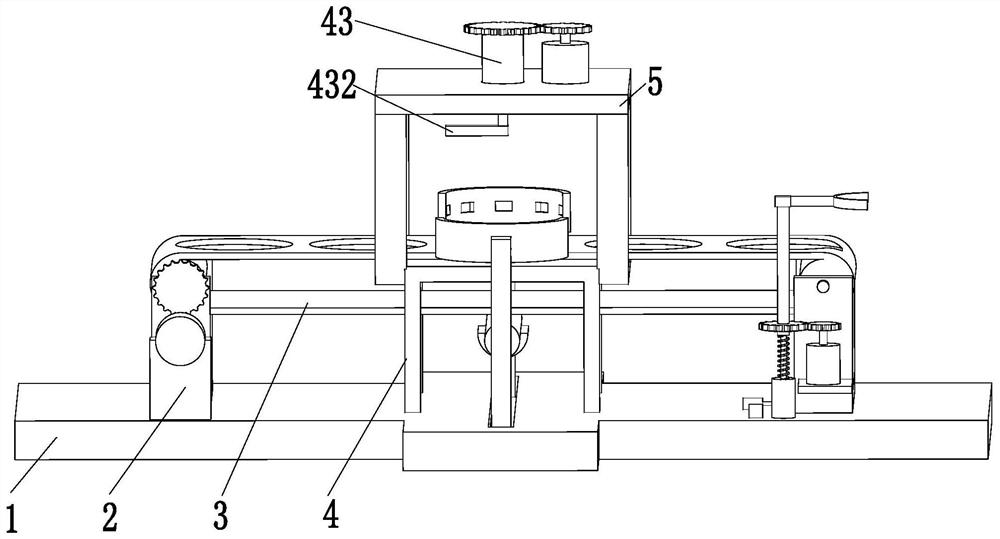

[0028] Such as Figure 1 to Figure 4 As shown, a corrugated packaging carton making and forming processing machine includes a fixed base 1, a transmission device 2, a transmission belt 3, a mounting frame 4 and a mounting plate 5, the upper end of the fixed base 1 is provided with a transmission device 2, and the transmission device The upper end of 2 is connected with the conveying belt 3 through the mode of sliding fit, and the circular fixing groove with the same radius is evenly arranged on the described conveying belt 3; A mounting plate 5 is fixed.

[0029] The fixed base 1 includes a fixed base plate 11, a pressure maintaining mechanism 12 and a docking mechanism 13. The upper middle part of the fixed base plate 11 is equipped with a pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com