Fireproof door system

A technology of fire doors and door openings, which is applied in the field of fire door systems, can solve the problems of docking rails and fixed rails that cannot be docked, and achieve the effects of improved docking accuracy, simple docking methods, and simple overall moving tracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

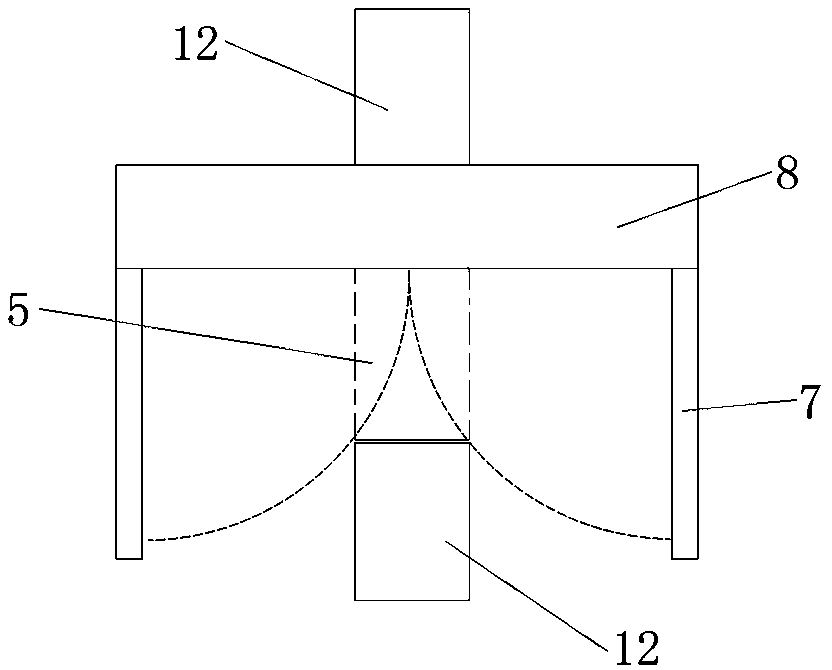

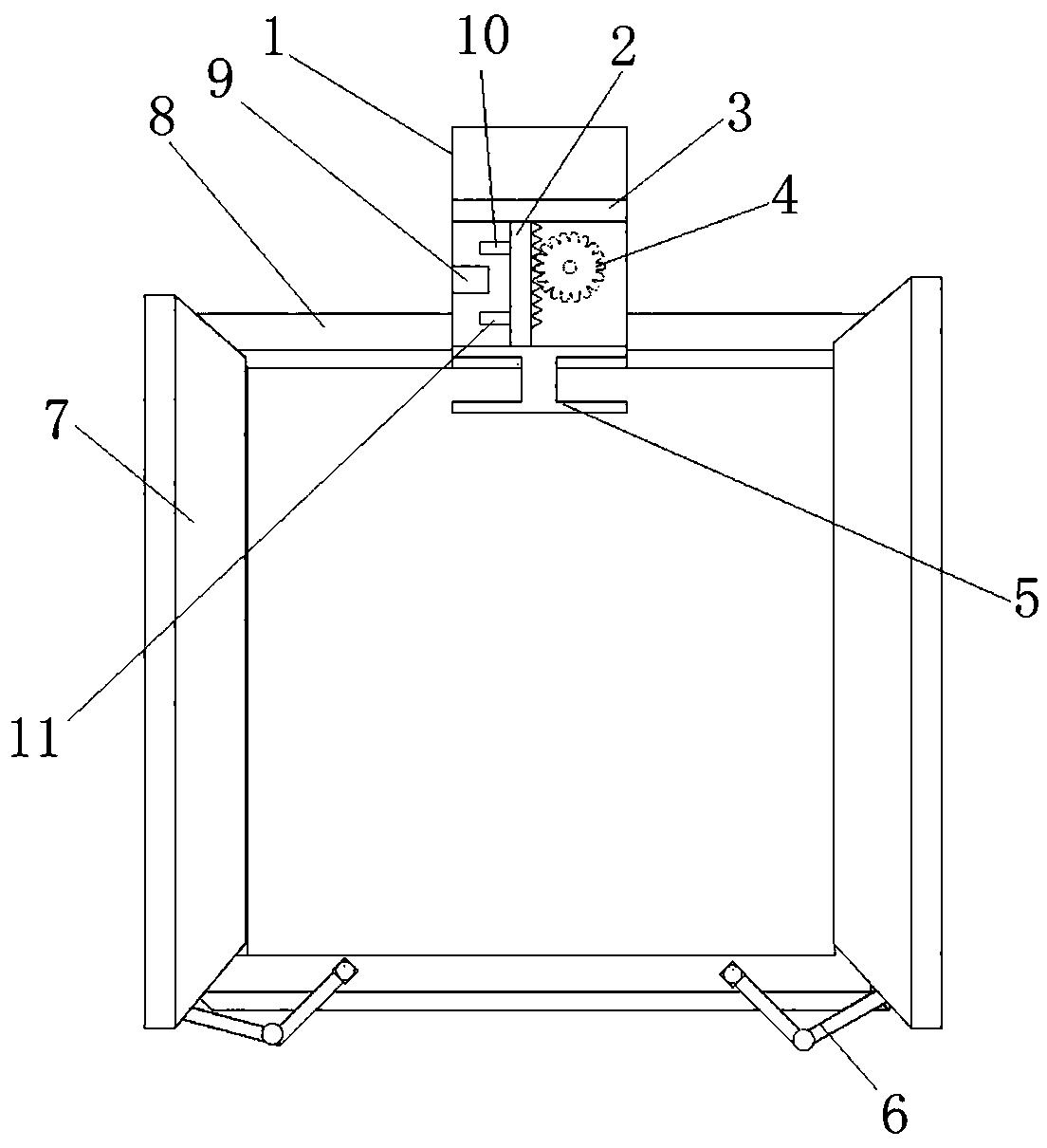

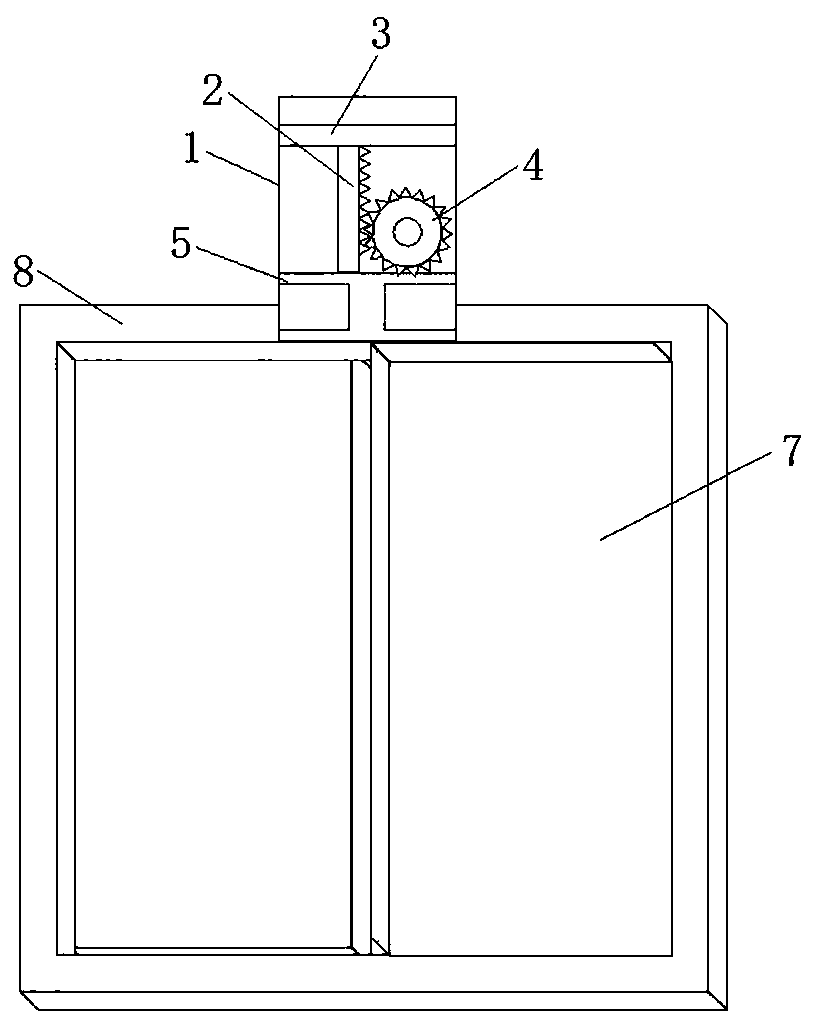

[0027] The fire door system of the present invention includes a door frame and a fire door. The fire door is installed in the door opening of the door frame. The door frame and the fire door can cooperate to isolate the two sides of the fire door. The track of the inspection robot is disconnected at the fire door, and is divided into fixed tracks arranged on both sides of the fire door and docking tracks corresponding to the fire door. The fire door system also includes a storage tank, the storage tank is located on one side of the fire door, the slot faces the door opening, the docking track is set in the storage tank, and driven by the linear drive mechanism, the docking track can move back and forth along a straight line to achieve The docking of the fixed track and the retraction from the fixed track to the receiving groove. The fire door system of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com