Multidirectional pipeline butt joint device

A docking device and pipeline technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of low efficiency, poor precision, and inconvenient operation of pipe fittings, so as to improve the scope of use and practicality of use performance, efficiency improvement, and fast docking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

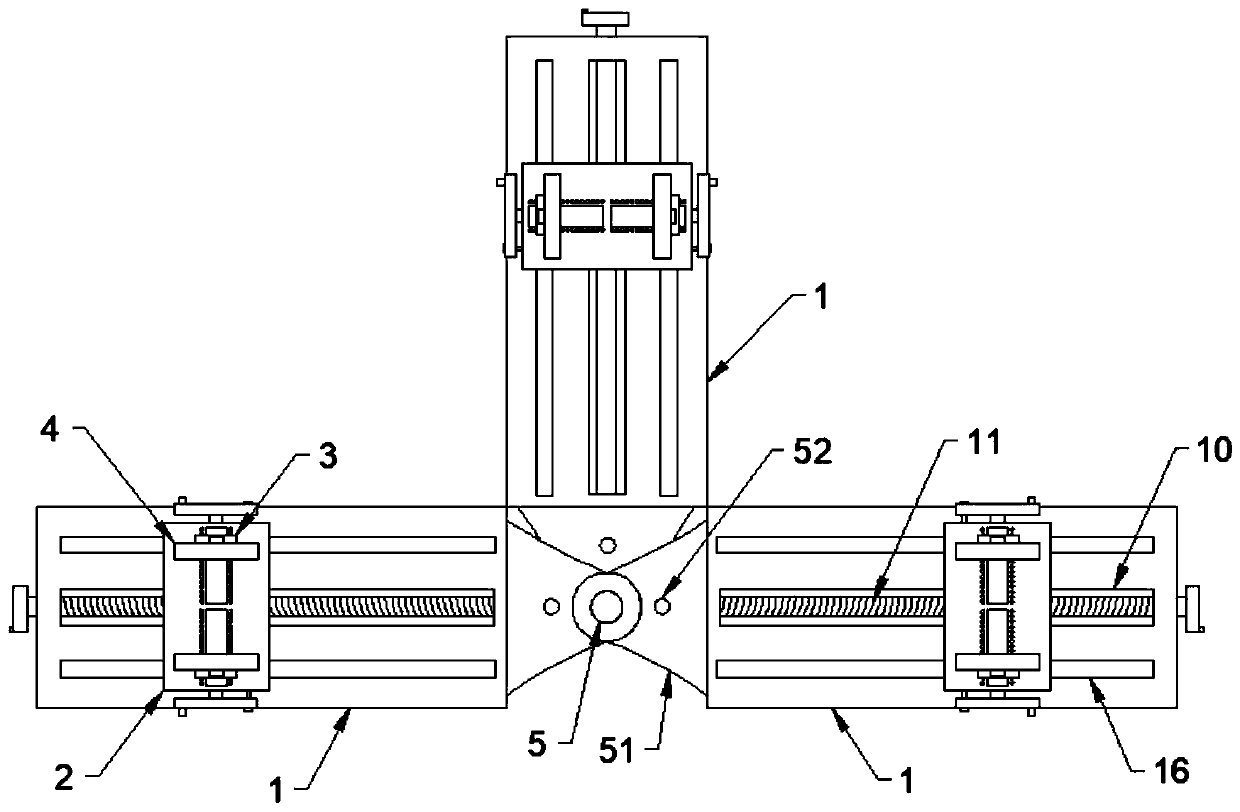

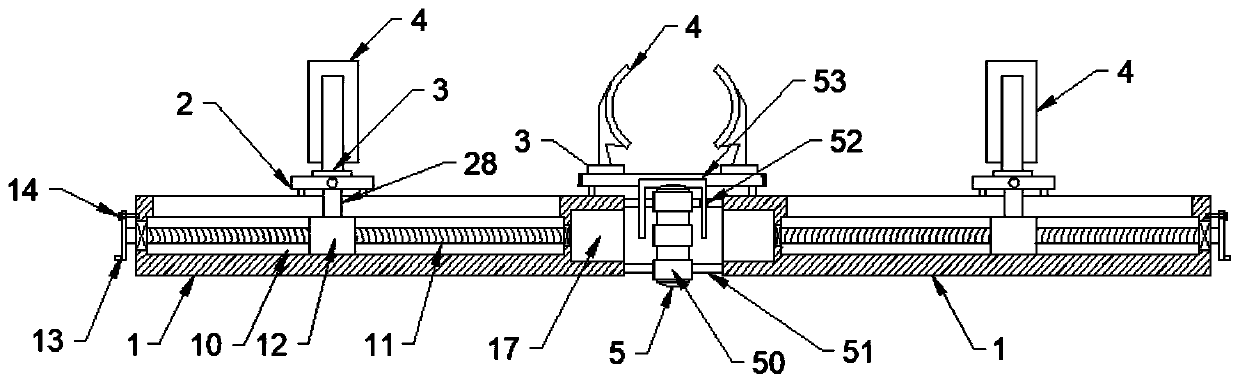

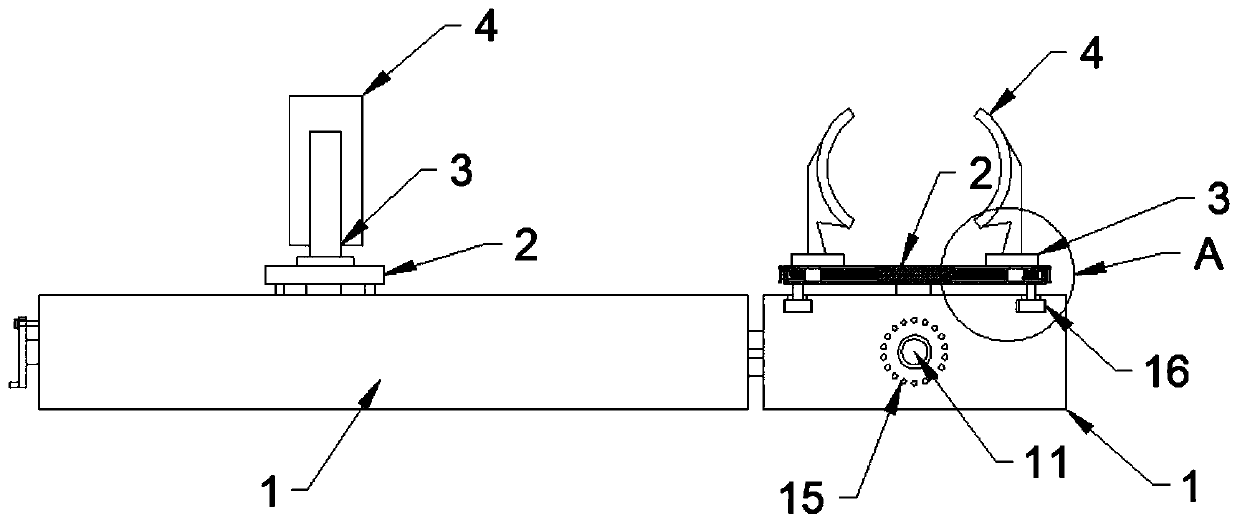

[0025] see Figure 1~5 , in an embodiment of the present invention, a pipe multi-directional docking device, including a sliding base 1, a docking slide 2, a clamp slide 3 and a pipe splint 4, the front and rear sides of the top of the sliding base 1 are provided with clamping pipes The pipe splint 4 is installed on the top surface of the docking slide 2 through the clamp slide 3, and the top surface of the sliding base 1 is provided with a docking adjustment device that drives the docking slide 2 to move laterally. A pipe diameter adjusting device for adjusting the clamping pipe diameter of the pipe splint 4 is installed on the top surface of the seat 3. One end of the sliding base 1 is fixed on the rotating column 5 by rotating the connecting rod 51, and the rotating column 5 is vertical. It is arranged on one side of the side wall of the sliding base 1 , and a plurality of sliding bases 1 are rotatably fixed on the rotating column 5 , and an angle limiting mechanism for lim...

Embodiment 2

[0034] see figure 2 with Image 6 , the difference between this embodiment and embodiment 1 is:

[0035] The side wall of the sliding base 1 on one side of the rotating column 5 is provided with an open-ended rotating groove 17 on the front, rear and right sides. The rotating groove 17 provided here is mainly when the adjacent sliding base 1 rotates around the rotating column 5. In order to prevent the side wall of the sliding base 1 from drying out when the rotating connecting rod 51 rotates, the rotation angle range of the sliding base 1 is increased.

[0036] The front and rear panels of the docking slide 2 are vertically fixed with a scale pointer 29, and the ends of the scale pointers 29 on the front and rear sides of the docking slide 2 are respectively located outside the front and rear panels of the sliding base 1, and the front and rear panels of the sliding base 1 are horizontally A scale 18 is provided, and the end of the scale pointer 29 points to the scale 18. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com