Magnetic collector for magnetic pulse forming

A magnetic pulse forming and magnetic collector technology, applied in the field of magnetic collectors, can solve the problems of forming production chain damage, short-circuit of the longitudinal seam of the magnetic collector and structural damage, reduction of the insulation capacity of the magnetic collector, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

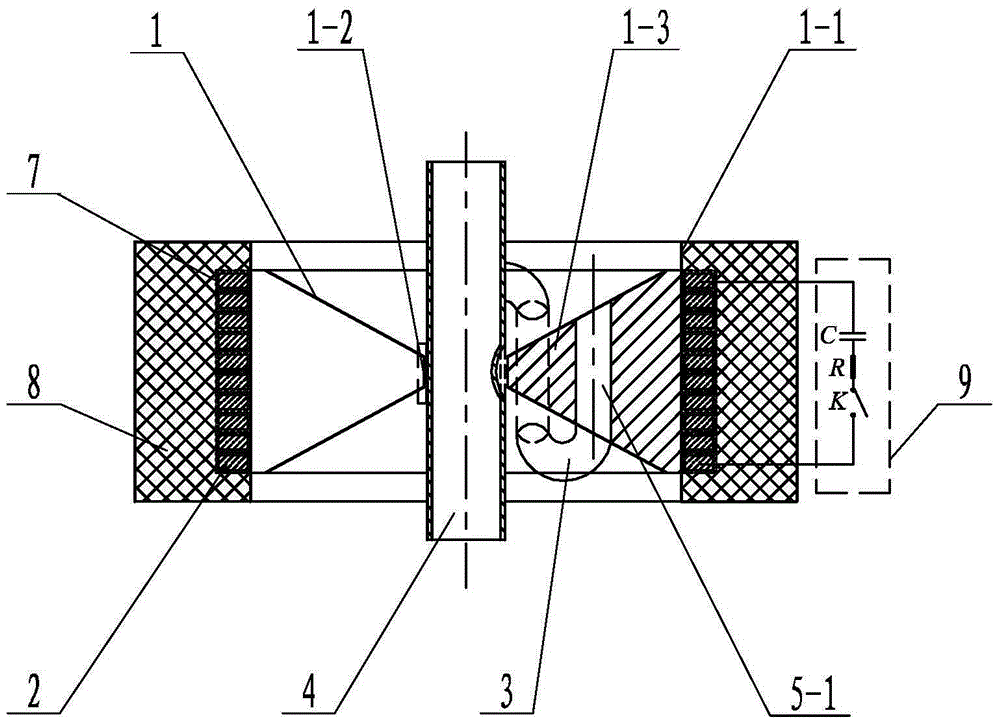

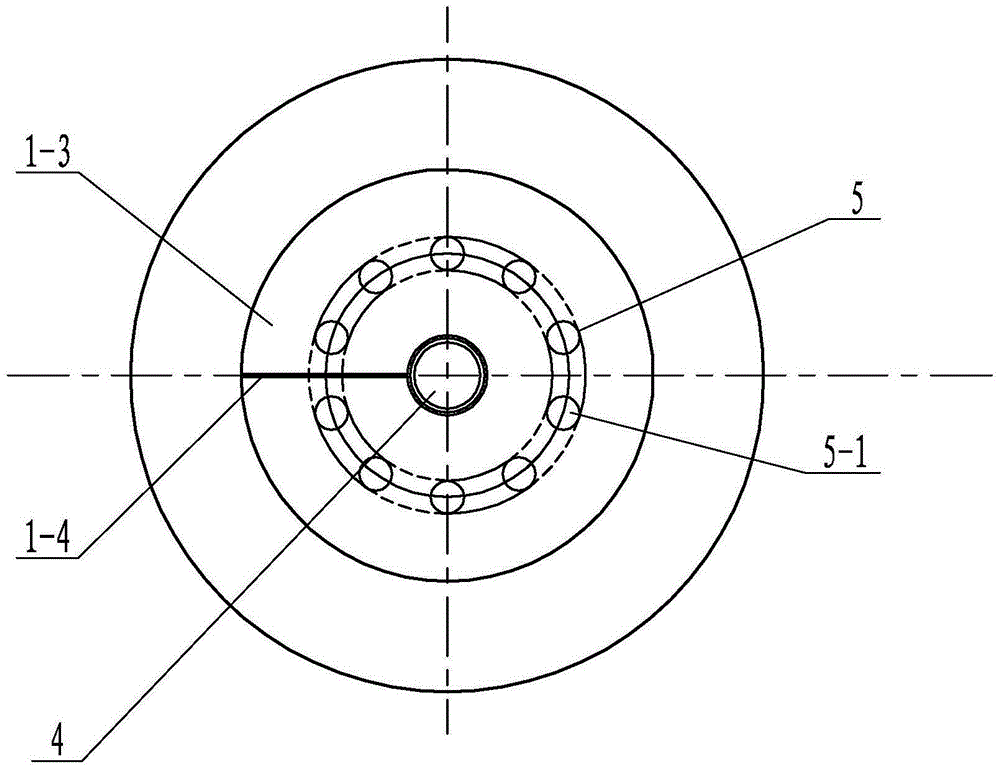

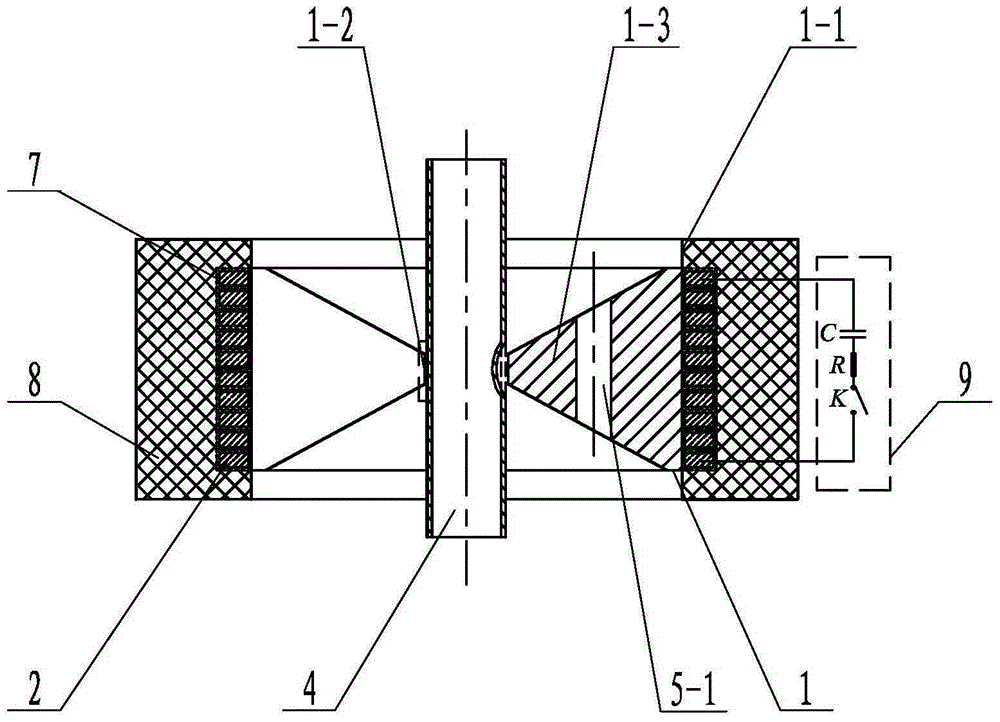

[0020] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment. This embodiment includes a magnetic collector body 1 and a coil 2. The magnetic collector body 1 includes an outer casing 1-1, an inner casing 1-2, and a longitudinal arm 1-3. The coil 2 is sleeved on the outer casing. Outside the body 1-1, the outer wall of the outer body 1-1 is set opposite to the inner wall of the coil 2, the inner body 1-2 is set inside the outer body 1-1, and the inner body 1-2 is provided with a tube blank 4, and the inner body 1-2 The inner wall of the sleeve body 1-2 is set opposite to the outer wall of the tube blank 4, and the outer sleeve body 1-1 and the inner sleeve body 1-2 are fixed and connected as a whole through the longitudinal arm 1-3. There is a longitudinal slit 1-4 in the process, the outer casing 1-1, the inner casing 1-2 and the longitudinal arm 1-3 are cut apart by the longitudinal slit 1-4, and insulating material is added in the longit...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 and figure 2 To describe this embodiment, the longitudinal section of the magnet collector body 1 in this embodiment is trapezoidal or T-shaped. The magnetic collector can be a single-slit overall structure or a symmetrical split structure. The cross-sectional shape of the magnetic collector can be trapezoidal or approximately trapezoidal, or T-shaped. Other structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 and figure 2 The present embodiment is described. In this embodiment, the longitudinal length of the inner sleeve body 1-2 is smaller than the longitudinal length of the outer sleeve body 1-1. Other structures and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com