Automatic baiting needling device of vehicle roof board production chain

An automatic feeding and acupuncture device technology, applied in the field of mechanical structure, can solve the problems of reduced production efficiency of automatic assembly line, inability to pick up soft materials such as carpets, low positioning efficiency and positioning accuracy, etc., to reduce labor intensity of workers, The structure is simple and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

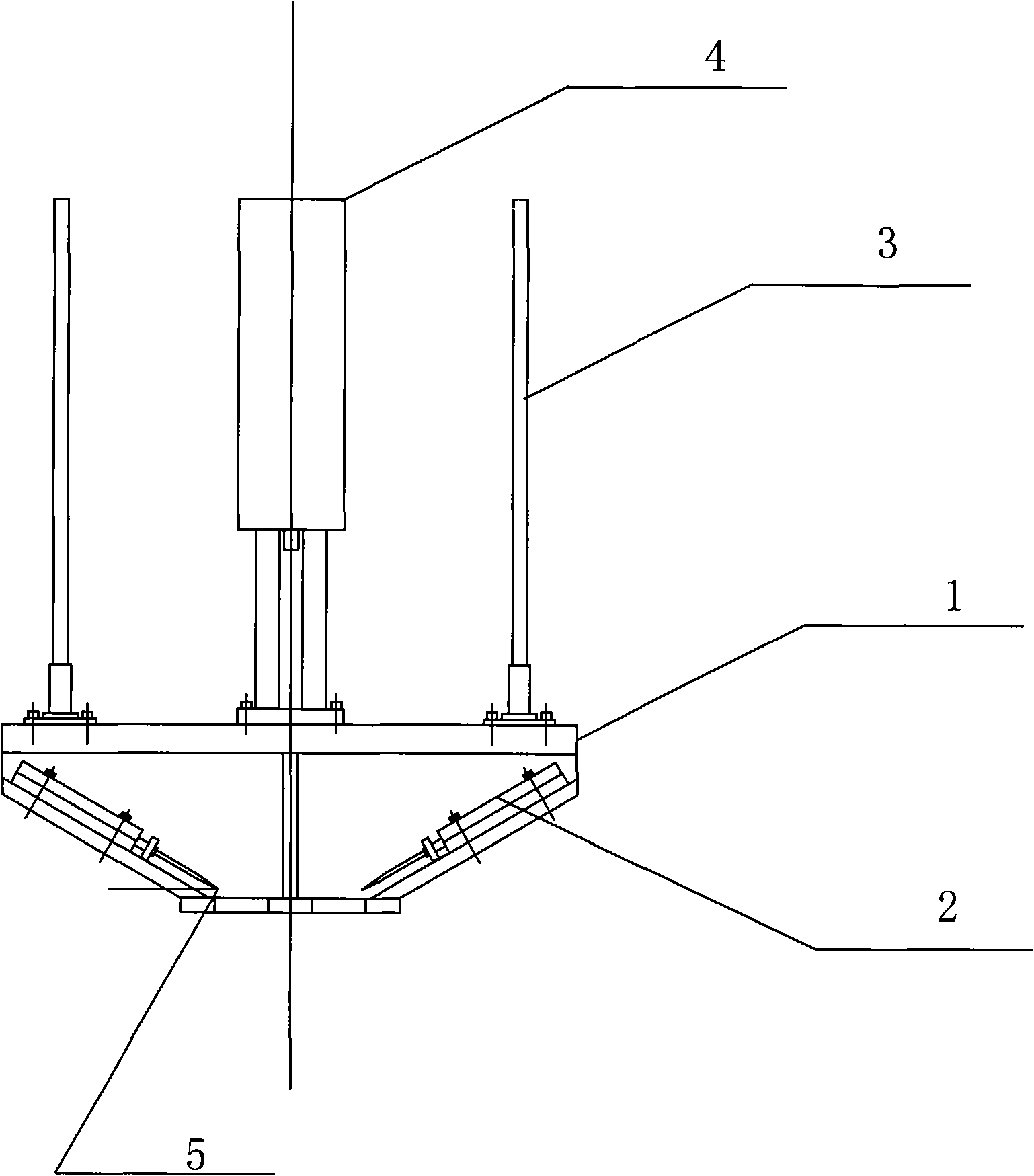

[0010] The invention comprises a cylinder base fixing frame 1, a slanting slide seat cylinder 2, a guide column 3, a lifting slide seat cylinder 4, and a needle 5. The present invention adopts to respectively install lifting slide seat cylinder 4, oblique thorn slide seat cylinder 2 and guide column 3 on the cylinder base fixed frame 1, and described oblique thorn slide seat cylinder 2 is provided with needles 5.

[0011] The invention is fixed on the suction cup automatic feeding movable frame, and moves up and down together with the suction cup automatic feeding mechanism. When the automatic feeding mechanism of the suction cup is lowered in place, the lifting slide cylinder 4 of the needle punching mechanism moves downward to stick to the raw material, and the inclined needle slide cylinder 2 drives the needle 5 to penetrate into the material, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com