Sustainable method for recovery of petroleum

a sustainable method and petroleum technology, applied in earth drilling, fluid removal, borehole/well accessories, etc., can solve the problems of complex viscosity-reducing agent, high cost of procedure, chemical, physical, physico-chemical and biological disequilibrium in said environment, etc., to improve the flow within the reservoir, reduce the viscosity of said viscous oil, and reduce the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0095]The example provided below presents a specific application of the invention to an oil produced in Brazil; due to the high-viscosity characteristics of the type of Brazilian paraffinic petroleum denominated Nativo Oeste (API-13, viscosity 3500 cP) the present invention was applied utilising a number of more-available substances having been tested with the objective of use as viscosity-reducing additives in the injection operation through injection wells in production activities.

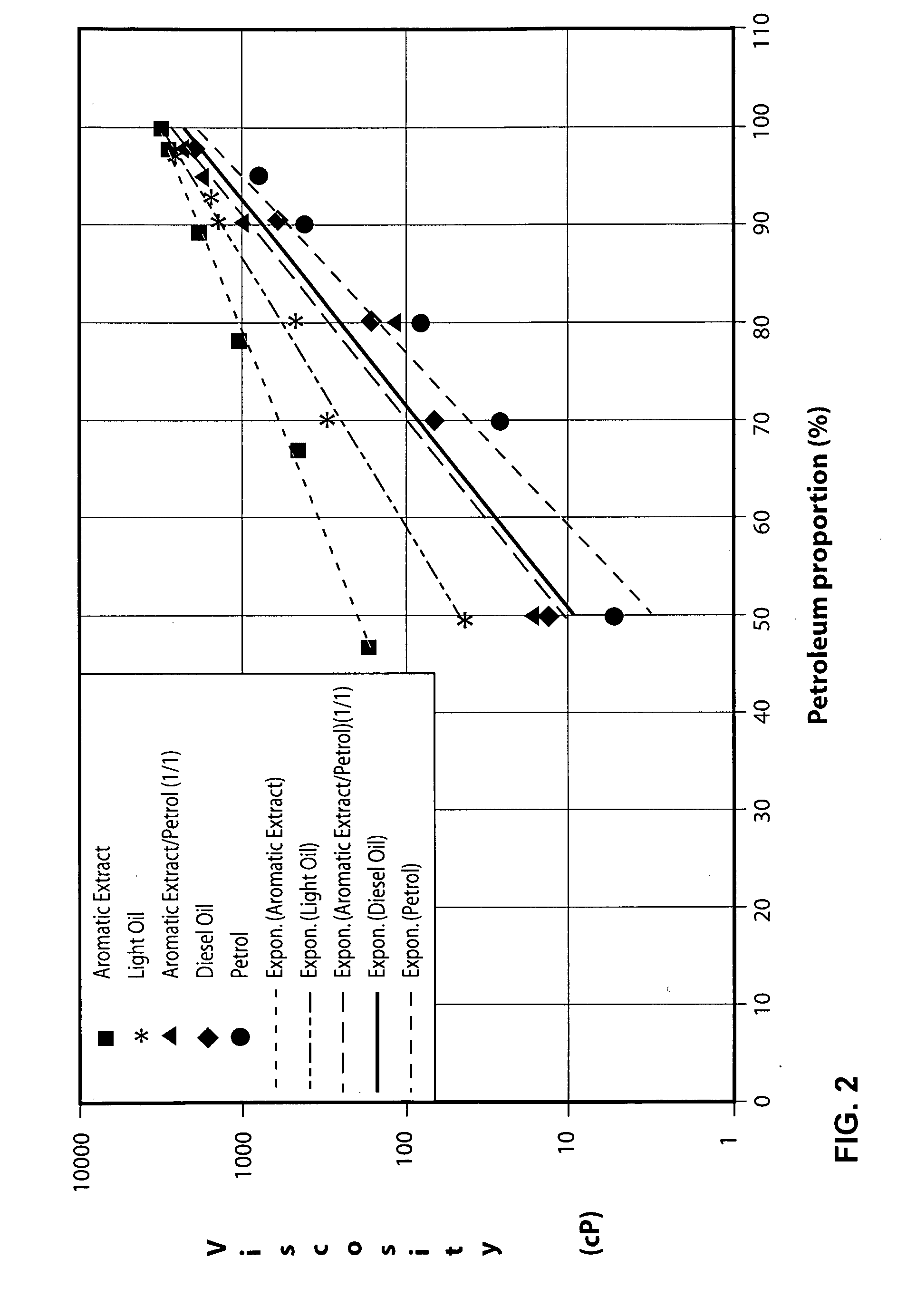

[0096]The application of the present invention in the rheology determination tests with the objective of selecting a more appropriate viscosity reducer for use in the field to render viable steam injection into a formation through the injection well, led to the graph shown in FIG. 2.

[0097]In accordance with FIG. 2, diesel achieves the result of lowering viscosity from 3500 cP to less than 250 cP at concentrations of solely 15-20%, placing it in an advantageous position with respect to the other reducers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com