Method for detecting left parts and device thereof

A technology of spare parts and leakage, which is applied in the direction of program control, instrument, computer control, etc. in the sequence/logic controller, and can solve the problems of high packaging cost, poor practicability, and long labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

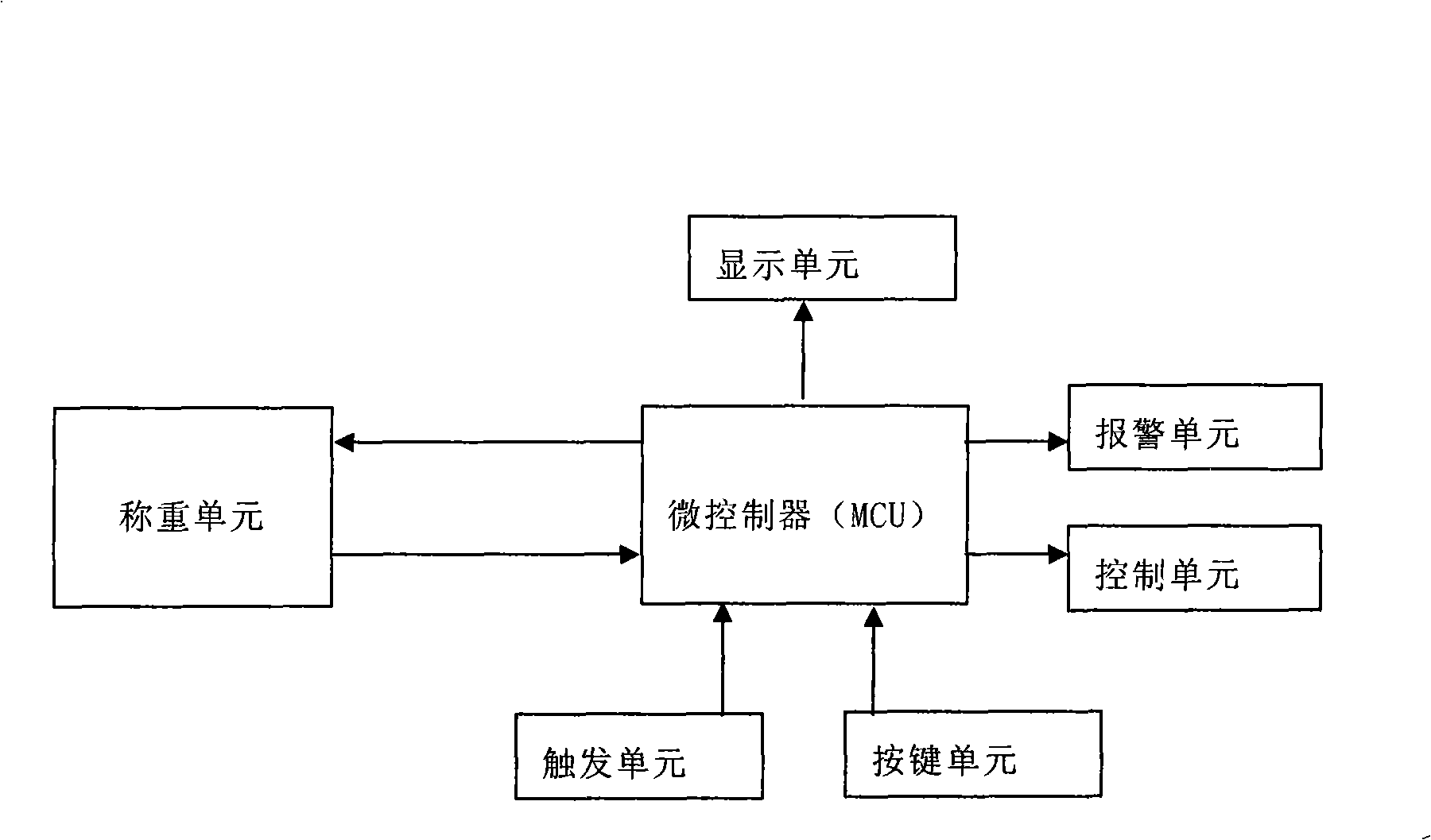

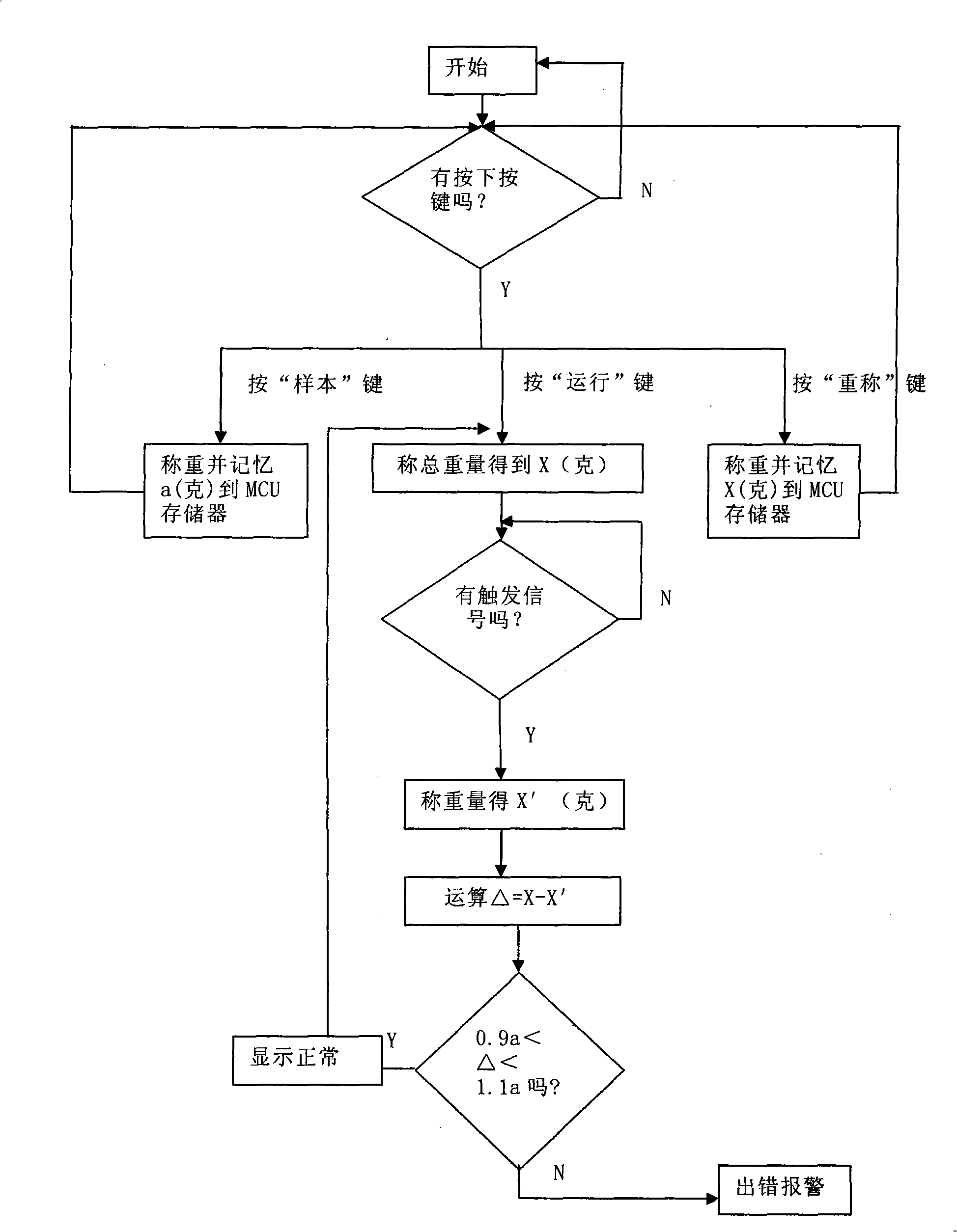

[0018] see figure 1 Shown, a kind of device of the present invention that detects missing spare parts comprises a weighing unit, a microcontroller (MCU) connected with the weighing unit, a trigger unit connected with the microcontroller, a button unit, a display unit, and an alarm unit with the control unit. Wherein, the weighing unit has an RS232 interface, and it performs data transmission with the MCU through the RS232 interface.

[0019] The weighing unit is an electronic scale with adjustable precision, memory function and RS232 output interface, which is used for weighing. Weigh the total weight of a spare part (including the box and all spare parts of a certain type contained in the box), and mark it as X grams; weigh a single sample of spare parts, and obtain the weight of a single spare part as a gram; and when triggered by the trigger signal each time, re-weigh the weight of the spare part, which is called X' gram. Whether the weight (data) of the spare part chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com