Intelligent control system for mine full-production chain

A management and control system and production chain technology, applied in the field of mine production, can solve problems such as difficulty in analysis, increased difficulty in system management and maintenance, and no occurrences, and achieve the effect of network security, efficient scheduling management and decision-making command

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

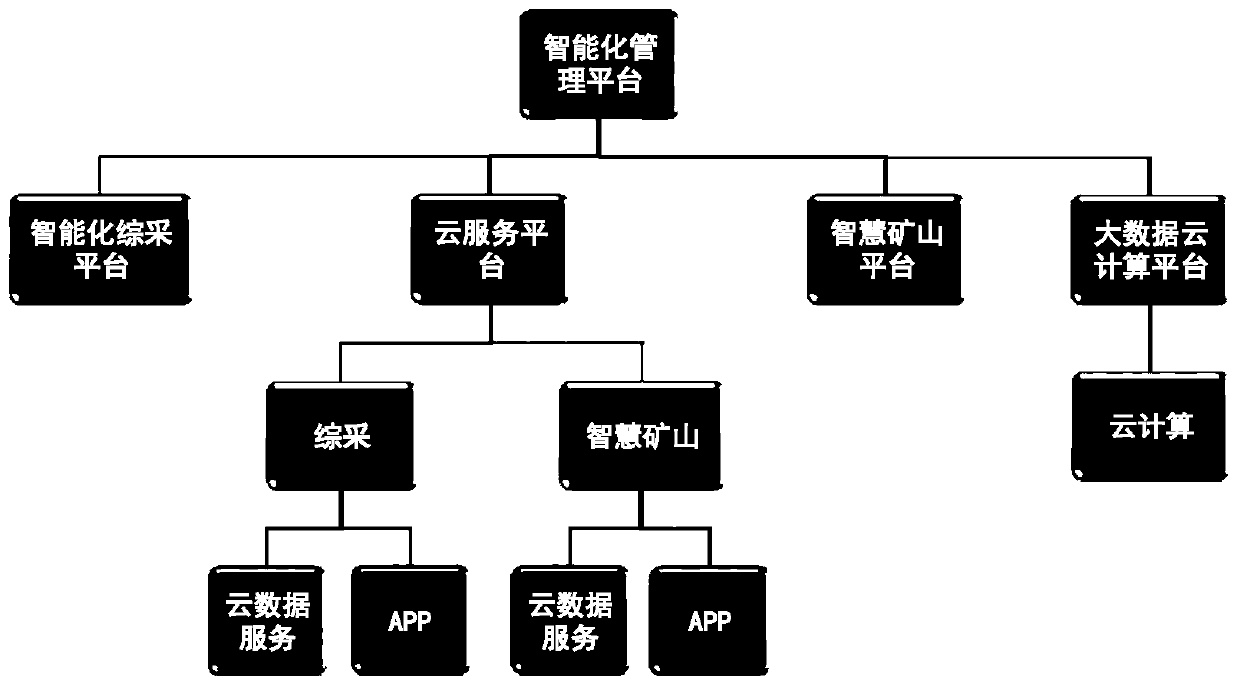

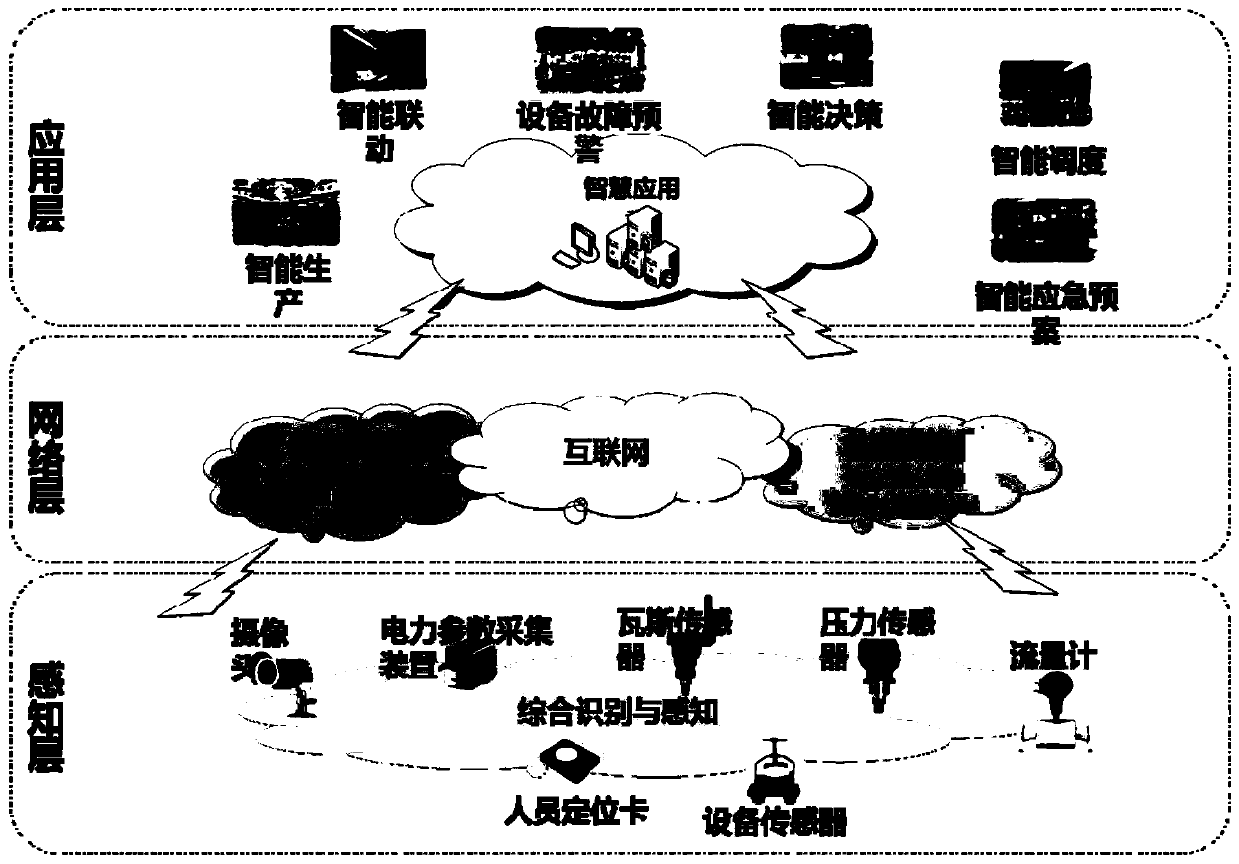

[0043] see Figure 1-3 As shown, the present invention provides an intelligent management and control system for the entire mine production chain, including: an intelligent management platform, an intelligent fully mechanized mining platform and an intelligent mine platform interconnected with the intelligent management platform through a network, and the intelligent management platform It is also interconnected with the cloud service platform through the network, and the cloud service platform is connected with the client through the network;

[0044]The intelligent management platform includes a monitoring platform for monitoring the working conditions of the intelligent fully mechanized mining platform and the intelligent mine platform; a storage platform for storing various real-time working parameter information of the intelligent fully mechanized mining platform and the intelligent mine platform; The analysis platform realizes production guidance and safety guidance for ...

Embodiment 2

[0082] see Figure 5 As shown, it is a block diagram of another intelligent management and control system for the whole production chain of a mine provided in this embodiment. The system includes an intelligent management platform and an intelligent operation and maintenance service cloud platform interconnected through a network. It is connected with substation system, water supply and drainage pump room system, main transport belt system, main ventilator room system, compressor room system, intelligent mechanized mining platform, fixed gas drainage pump room, local ventilator, overhead passenger equipment, Selective washing system and downhole water treatment system; among them,

[0083] The substation system, water supply and drainage pump room system, main ventilator room system, compressor room system, intelligent fully mechanized mining platform, fixed gas drainage pump room, and local ventilators can all realize the unification of the ground remote data interface, Remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com