Hybrid genetic algorithm-based MES (Manufacturing Execution System) production planning and scheduling method

A hybrid genetic algorithm and production planning technology, applied in the direction of comprehensive factory control, instrumentation, and comprehensive factory control, can solve the problems of inefficient MES production scheduling method, enhance local search ability, avoid falling into premature convergence, and maintain population diversity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

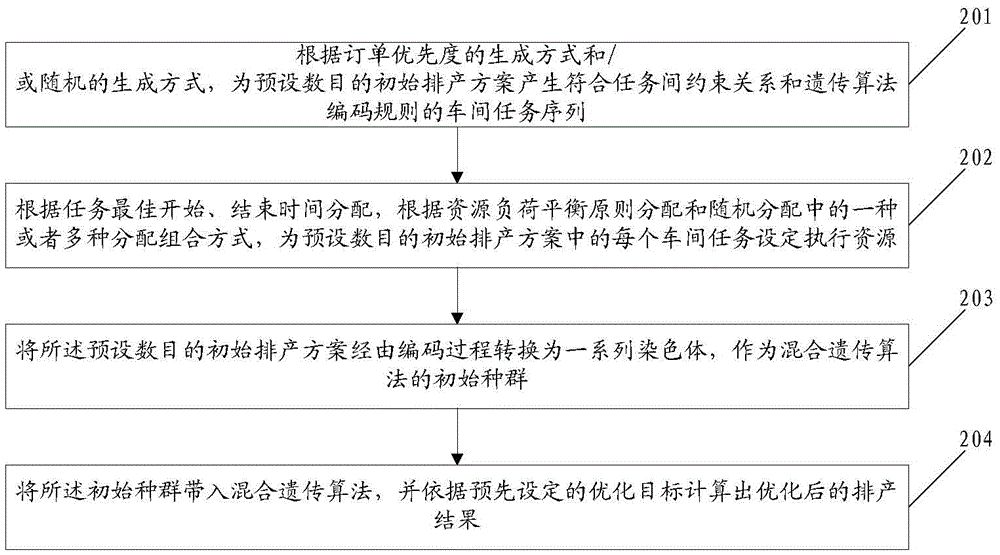

[0059] like figure 1 Shown is a MES production planning and scheduling method based on a hybrid genetic algorithm provided by the present invention, there are one or more orders in the MES production planning and scheduling, and there are one or more execution resources in the workshop, the Methods include:

[0060] In step 201, according to the generation of order priority (OS initialization based on order priority, abbreviated as: OSIOP) method and / or random generation (Random OS initialization, abbreviated as: ROSI) method, generate a preset number of initial production scheduling schemes that meet the constraints between tasks Workshop task sequences for relational and genetic algorithm coding rules;

[0061] In step 202, according to the task optimal start and end time allocation (resource selection according to appropriate planned time, abbreviated as: RSAPT), according to resource load balancing principle allocation (resource selection for working time balance, abbrevi...

Embodiment 2

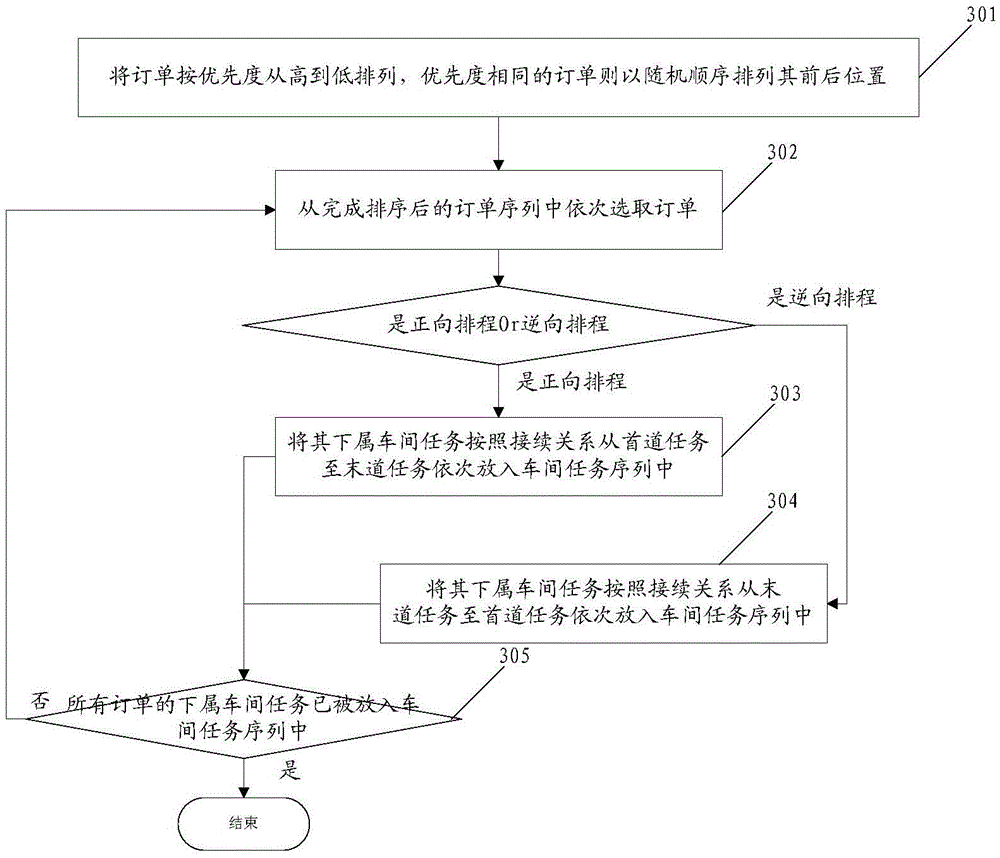

[0073] The embodiment of the present invention further elaborates on the technical features involved in step 201 in the first embodiment, and gives specific examples of its implementation, wherein, according to the generation method of the order priority described in step 201, the generated Inter-task constraint relations and workshop task sequences of genetic algorithm encoding rules, such as figure 2 shown, including:

[0074] Step 301: arrange the orders from high to low priority, and arrange the front and back positions of orders with the same priority in random order;

[0075] Step 302: Orders are sequentially selected from the sorted order sequence. If it is an order that is forward scheduled, go to step 303; if it is an order that is reverse scheduled, go to step 304.

[0076] Step 303, putting its subordinate workshop tasks into the workshop task sequence sequentially from the first task to the last task according to the succession relationship;

[0077] Step 304, p...

Embodiment 3

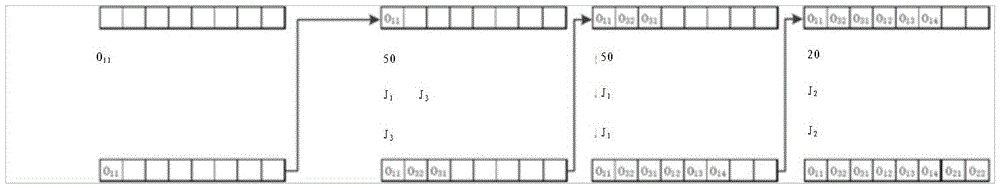

[0081] The embodiment of the present invention further elaborates on the technical features involved in step 201 in the first embodiment, and gives a specific example of its implementation, wherein, according to the random generation method described in step 201, a Constraint relationships and genetic algorithm coding rules for workshop task sequences, such as Figure 4 As shown, the specific implementation is:

[0082] Step 401: put the workshop tasks included in the order into the workshop task sequence in any order;

[0083] Step 402: Generate an optional shop floor task set Oa, select the shop floor tasks without previous tasks from the forward scheduled orders, and select the shop floor tasks without subsequent tasks from the unstarted reverse scheduled orders, and then select these Workshop tasks are put into Oc;

[0084] Step 403: Randomly select a workshop task Oc from Oa to be placed in the next position of the workshop task sequence, and then move Oc out of Oa;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com