System for dynamically predicating power load of iron and steel enterprise in short period

A power load and dynamic forecasting technology, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as poor reusability and adaptability, poor availability of forecast results, and no consideration of real-time changing factors in the process, etc., to achieve good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The specific implementation process:

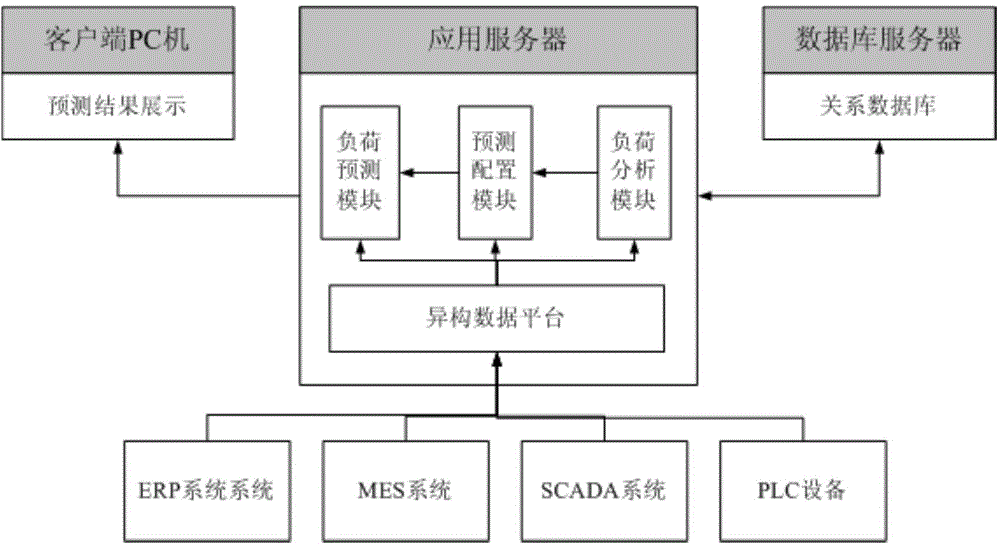

[0067] 1. If figure 1 Shown is the system structure diagram. The hardware includes application server, database server, client PC and network equipment connected to the computer. The heterogeneous data platform and forecasting system are deployed on the application server, the relational database is installed on the database server, and the client software is installed on the client PC or browses the forecast results in B / S mode.

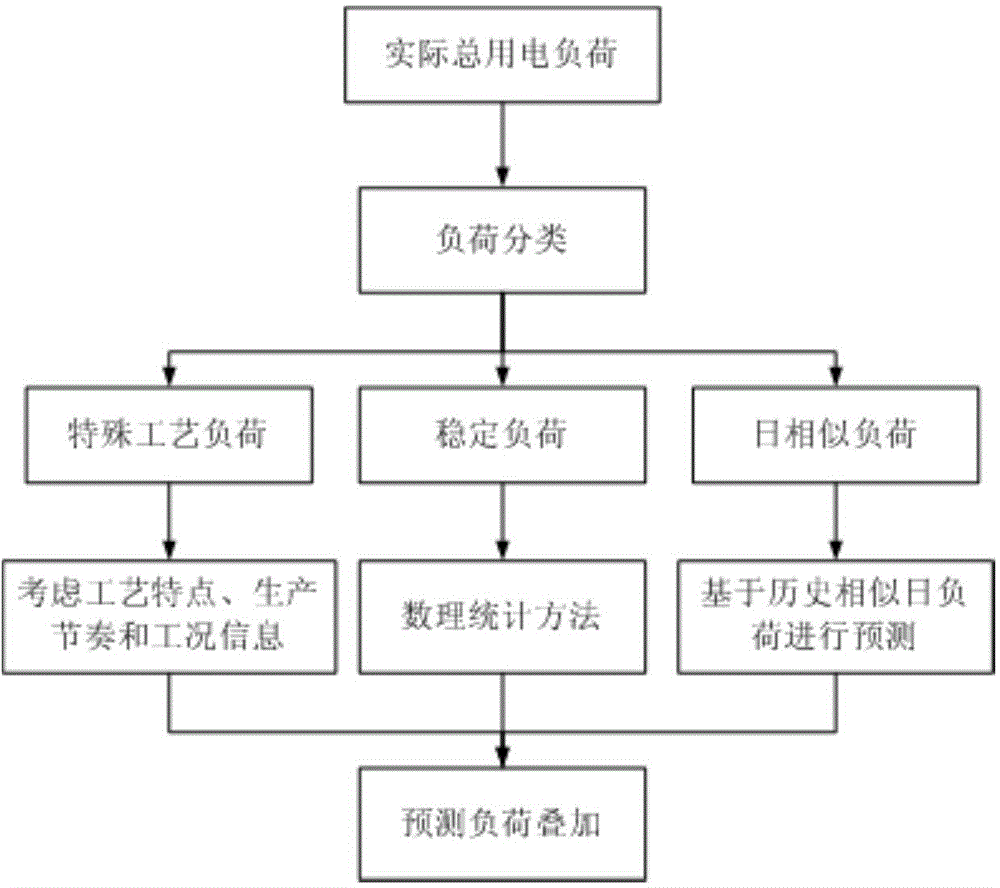

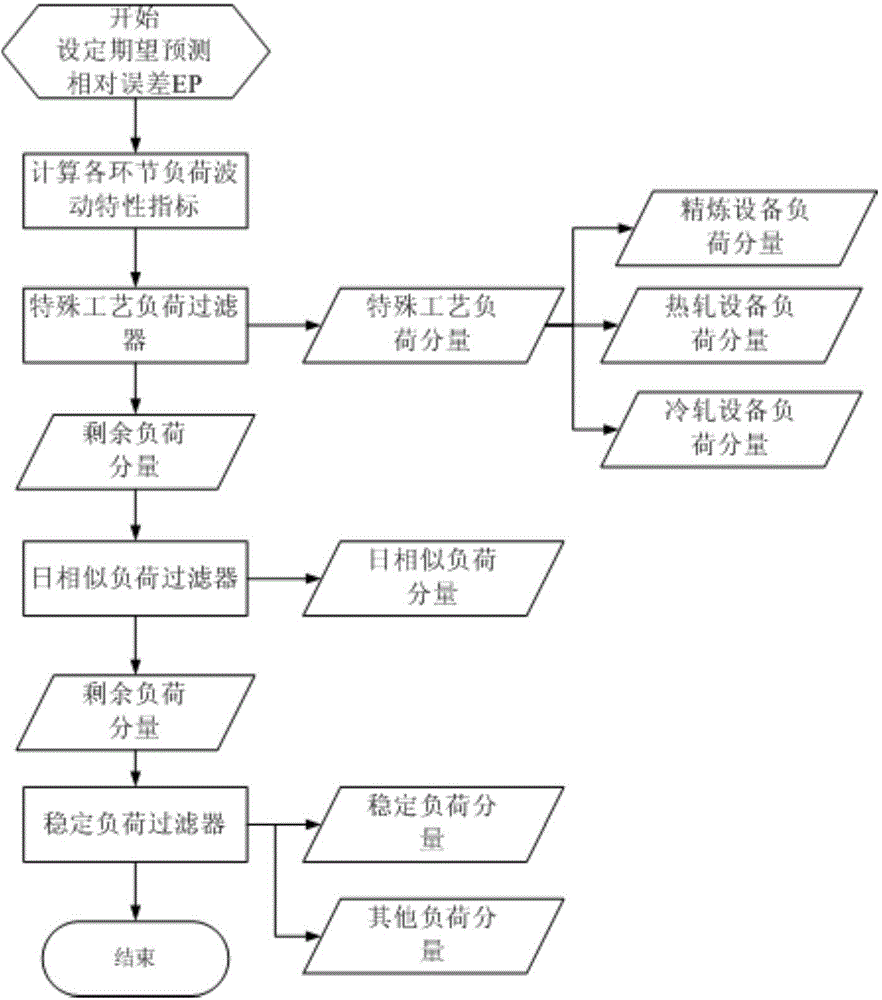

[0068] 2. If Figure 3-4 Run the flowchart for the Predictive System Load Analysis module. Start the load analysis module service, and use the average value, standard deviation, maximum value, minimum value, average fluctuation rate, maximum fluctuation rate, minimum fluctuation rate, minimum, maximum, average load as a percentage of the total load, load trend and total load trend The gray correlation degree is used as a quantitative index, and the total load is decomposed and classified based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com